A kind of high-boron iron-based erosion-corrosion resistant alloy and preparation method thereof

An erosion-resistant, iron-based technology, applied in the field of wear-resistant and corrosion-resistant metal materials, can solve the problems of high price and complicated preparation process, and achieve the effects of low production cost, simple process, and improved erosion and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

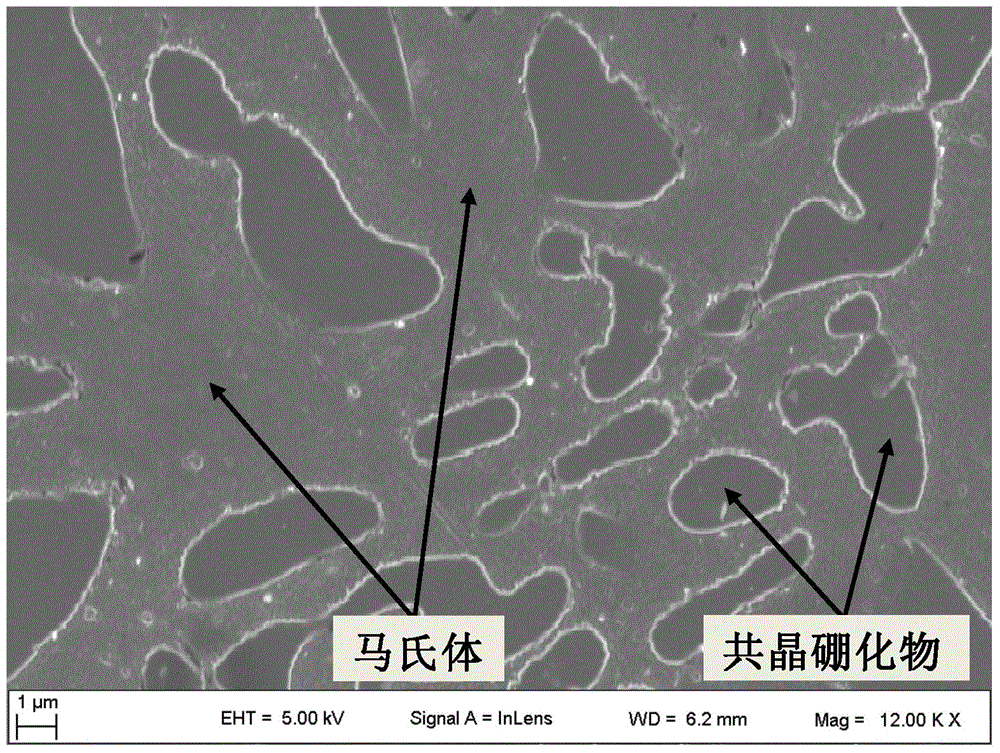

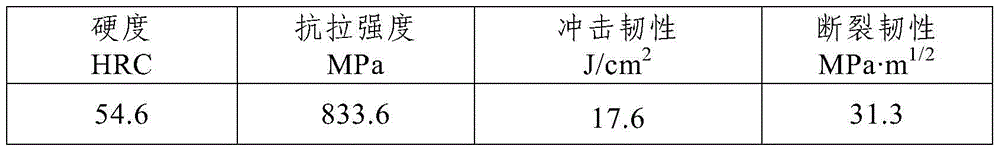

Embodiment 1

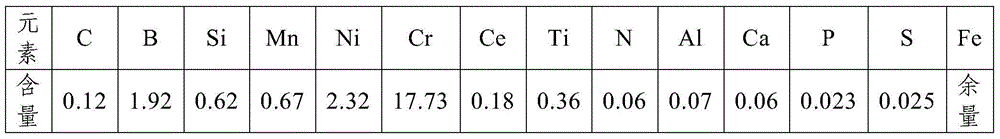

[0040] The high boron iron-based erosion corrosion resistant alloy of this embodiment is composed of the following components in weight percentage: C 0.12%, B 1.92%, Si 0.62%, Mn 0.67%, Ni 2.32%, Cr 17.73%, Ce0.18% , Ti 0.36%, N 0.06%, Al 0.07%, Ca 0.06%, P<0.03, S<0.03, the balance is Fe and other unavoidable impurities.

[0041] The high-boron iron-based erosion-resistant corrosion-resistant alloy of this embodiment is prepared by melting in a 500 kg intermediate frequency induction furnace, and the preparation method is specifically as follows:

[0042] Step 1, heating and melting pure iron and ferrochromium, adding ferrosilicon and ferromanganese to the molten solution after the molten solution is cleared, and then adding pure nickel plate, ferrotitanium and ferroboron;

[0043] Step 2. After the composition of the furnace is adjusted to pass, the temperature of the melt is raised to 1640°C, and then silicon-calcium alloy and aluminum are added to the melt to deoxidize, an...

Embodiment 2

[0053] The high boron iron-based erosion corrosion resistant alloy of this embodiment is composed of the following components in weight percentage: C 0.15%, B 1.76%, Si 0.57%, Mn 0.61%, Ni 2.56%, Cr 16.92%, Ce0.16% , Ti 0.41%, N 0.08%, Al 0.06%, Ca 0.08%, P<0.03, S<0.03, the balance is Fe and other unavoidable impurities.

[0054] The high-boron iron-based erosion-resistant corrosion-resistant alloy of this embodiment is prepared by melting in a 500 kg intermediate frequency induction furnace, and the preparation method is specifically as follows:

[0055] Step 1, heating and melting pure iron and ferrochromium, adding ferrosilicon and ferromanganese to the molten solution after the molten solution is cleared, and then adding pure nickel plate, ferrotitanium and ferroboron;

[0056] Step 2. After the composition of the furnace is adjusted to pass, the temperature of the melt is raised to 1620°C, and then silicon-calcium alloy and aluminum are added to the melt to deoxidize, an...

Embodiment 3

[0065] The high boron iron-based erosion corrosion resistant alloy of this embodiment is composed of the following components in weight percentage: C 0.16%, B 1.89%, Si 0.51%, Mn 0.66%, Ni 2.43%, Cr 18.12%, Ce0.15% , Ti 0.43%, N 0.06%, Al 0.07%, Ca 0.06%, P<0.03, S<0.03, the balance is Fe and other unavoidable impurities.

[0066] The high-boron iron-based erosion-resistant corrosion-resistant alloy of this embodiment is prepared by melting in a 500 kg intermediate frequency induction furnace, and the preparation method is specifically as follows:

[0067] Step 1, heating and melting pure iron and ferrochromium, adding ferrosilicon and ferromanganese to the molten solution after the molten solution is cleared, and then adding pure nickel plate, ferrotitanium and ferroboron;

[0068] Step 2. After the composition of the furnace is adjusted to pass, the temperature of the melt is raised to 1630°C, and then silicon-calcium alloy and aluminum are added to the melt to deoxidize, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com