A method of dyeing and rectifying the twisted and rectification of polyester cotton naturally bombed oblique fabric

A technology of twill fabric and processing method, which is applied in the direction of fabric surface trimming, textile material processing, mercerizing of indefinite length fabrics, etc., can solve the problem of increasing production costs, difficulty in accurately controlling the inclination, fabric strength, and adverse effects on physical and mechanical properties of hand feel, etc. problems, to achieve the effect of improving elasticity, reducing the degree of distortion, and plump feeling style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

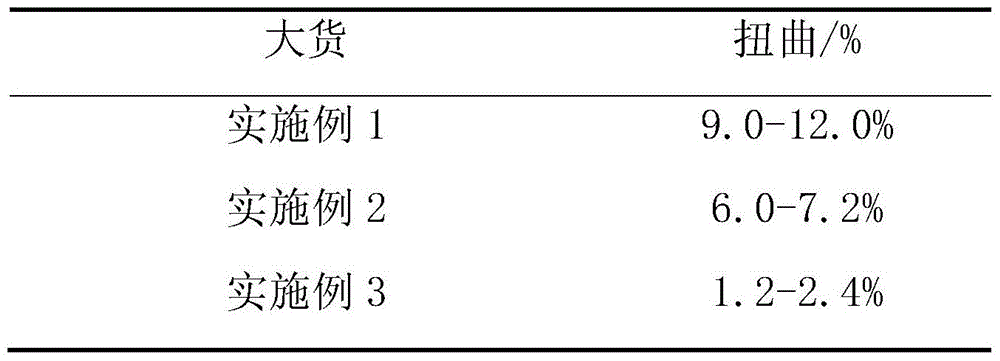

Examples

Embodiment 1

[0011] Material: 120*9045(55%T45%C)*45(55%T45%C), finished fabric width 57 / 58", right slanted 2 / 2;

[0012] The steps include singeing → desizing → mercerizing → shaping → preshrinking → code cloth, among which singeing: one positive and one negative gas singeing, the speed of the machine is 120m / min, and the oil volume is 12kg / h;

[0013] In the desizing process, amylase is used for desizing, the vehicle speed is 80m / min, stacked at 55°C for 35min, washed with water for 2 compartments at 85°C and 3 compartments at 55°C.

[0014] In the mercerizing process, the alkali concentration is 370g / L, and the fabric is normally dropped.

[0015] Shaping process, 120 ℃, polyurethane elastic finishing agent 50g / L, speed of 40m / min, normal falling cloth.

Embodiment 2

[0017] Material: 120*9045(55%T45%C)*45(55%T45%C), finished fabric width 57 / 58", right slanted 2 / 2;

[0018] The steps include singeing → desizing → mercerizing → shaping → preshrinking → code cloth, among which singeing: one positive and one negative gas singeing, the speed of the machine is 120m / min, and the oil volume is 12kg / h;

[0019] In the desizing process, amylase is used for desizing, the vehicle speed is 80m / min, stacked at 55°C for 35min, washed with water for 2 compartments at 85°C and 3 compartments at 55°C.

[0020] In the mercerizing process, the alkali concentration of 370g / L is used, and the speed of the clip chain is adjusted to ensure that the stroke of one side of the fabric is greater than that of the other side. When the fabric is loaded with alkali, it is skewed by 25cm, and the warp and weft are guaranteed to be perpendicular to each other when falling;

[0021] Shaping process, 120 ℃, polyurethane elastic finishing agent 50g / L, speed of 45m / min, normal...

Embodiment 3

[0023] Material: 120*9045(55%T45%C)*45(55%T45%C), finished fabric width 57 / 58", right slanted 2 / 2;

[0024] The steps include: singeing → desizing → mercerizing → primary setting → secondary setting → preshrinking → code cloth, among which singeing: one positive and one negative gas singeing, the speed of the machine is 120m / min, and the oil volume is 12kg / h;

[0025] In the desizing process, amylase is used for desizing, the vehicle speed is 80m / min, stacked at 55°C for 35min, washed with water for 2 compartments at 85°C and 3 compartments at 55°C.

[0026] In the mercerizing process, use an alkali concentration of 370g / L, adjust the chain speed of the cloth clips, reverse the skew by 25cm when the fabric is alkali-laden, and adjust the weft aligner after washing to ensure that the fabric falls normally;

[0027] Once setting, the temperature is 170°C, the water is squeezed, the speed of the vehicle is 30m / min, and the weft adjuster is adjusted to ensure that the fabric is sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com