Efficient tiny-dust-proof window gauze capable of releasing negative ions and manufacturing method thereof

A technology for anti-dust window screens and production methods, which is applied in the directions of chemical instruments and methods, insect prevention, lamination auxiliary operations, etc., can solve the problems of adding negative ion window screens, etc., and achieve the effects of reducing adverse effects, protecting health, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

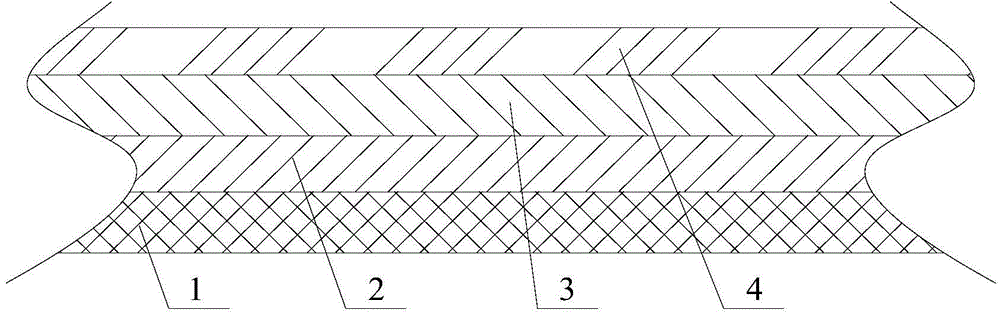

[0043] Embodiment 1, supporting layer 1 selects silk diameter as 0.02mm, 80 object glass fiber silk screens, on supporting layer 1 upper end face spraying is the negative ion functional film layer 4 that the thickness of 50 μ m is 50 μ m with tourmaline powder as the main raw material adding polyurethane adhesive, This type of window screen is lighter and thinner and is used in environments with better air quality.

[0044] Replace the original window screen of the building with the window screen made in this embodiment and carry out the 1-hour window ventilation experiment. The data are as follows:

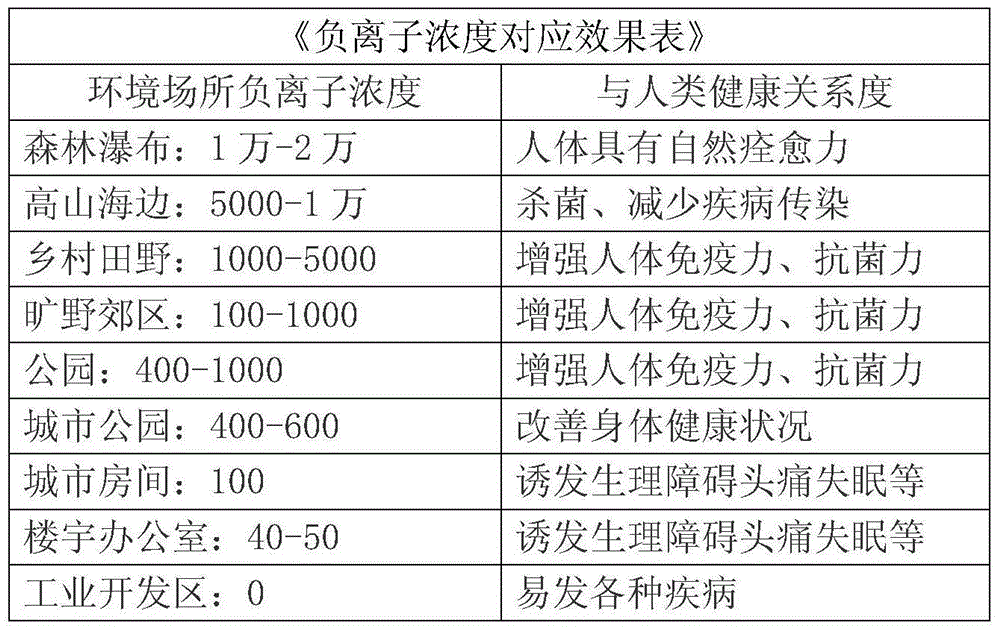

[0045] Before changing the window screen and opening the window for 1 hour to ventilate, the outdoor PM2.5 concentration is 120μg / m 3 , PM10 concentration is 308μg / m 3 , the negative ion concentration is 256 / cm 3 ; After opening the windows for 1 hour to ventilate, the indoor PM2.5 concentration is 110μg / m 3 , PM10 concentration is 280μg / m 3 , the negative ion concentration i...

Embodiment 2

[0047] Embodiment 2, the supporting layer 1 selects 304 stainless steel wire mesh with a wire diameter of 0.05mm and 30 meshes, and sprays a single square meter grammage of 15g / m on the upper end surface of the supporting layer 1 2 1. The polyethersulfone resin PES hot-melt adhesive mesh membrane with a pore size of 10 μm is used as the primary filter layer 2, and a negative ion functional membrane with a thickness of 20 μm, which is made of tourmaline powder as the main raw material and added with polyurethane adhesive, is sprayed on the upper surface of the primary filter layer 2 Layer 4.

[0048] Replace the original window screen of the building with the window screen made in this embodiment and carry out the 1-hour window ventilation experiment. The data are as follows:

[0049] Before changing the window screen and opening the window for 1 hour for ventilation, the outdoor PM2.5 concentration was 368 μg / m 3 , the negative ion concentration is 156 / cm 3 ; After opening t...

Embodiment 3

[0051] Embodiment 3, the support layer 1 selects a wire diameter of 0.05mm and 30 mesh polyethylene PE wire mesh, and sprays a single square meter grammage of 9g / m on the end surface of the support layer 1 2 , Polyethersulfone resin PES hot-melt adhesive mesh membrane with a pore size of 20 μm is used as the primary filter layer 2, and then the high polymer polypropylene PP material is used on the primary filter layer 2 to prepare micropores with a pore size of 2 μm by a melt blown process The membrane is used as the secondary filter layer 3, and the support layer 1, the primary filter layer 2, and the secondary filter layer 3 are hot-pressed on a hot press, and then the upper surface of the secondary filter layer 3 is sprayed with tourmaline powder as the main raw material. The thickness of the polyurethane adhesive is the negative ion functional film layer 4 of 10 μm.

[0052] Replace the original window screen of the building with the window screen made in this embodiment a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com