Plasma spray spectrometry ionization source

A technology of plasma and low-temperature plasma, which is applied in the field of mass spectrometry ionization source, can solve the problems of increasing energy consumption and achieve the effects of easy production and processing, expanded application range, and good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

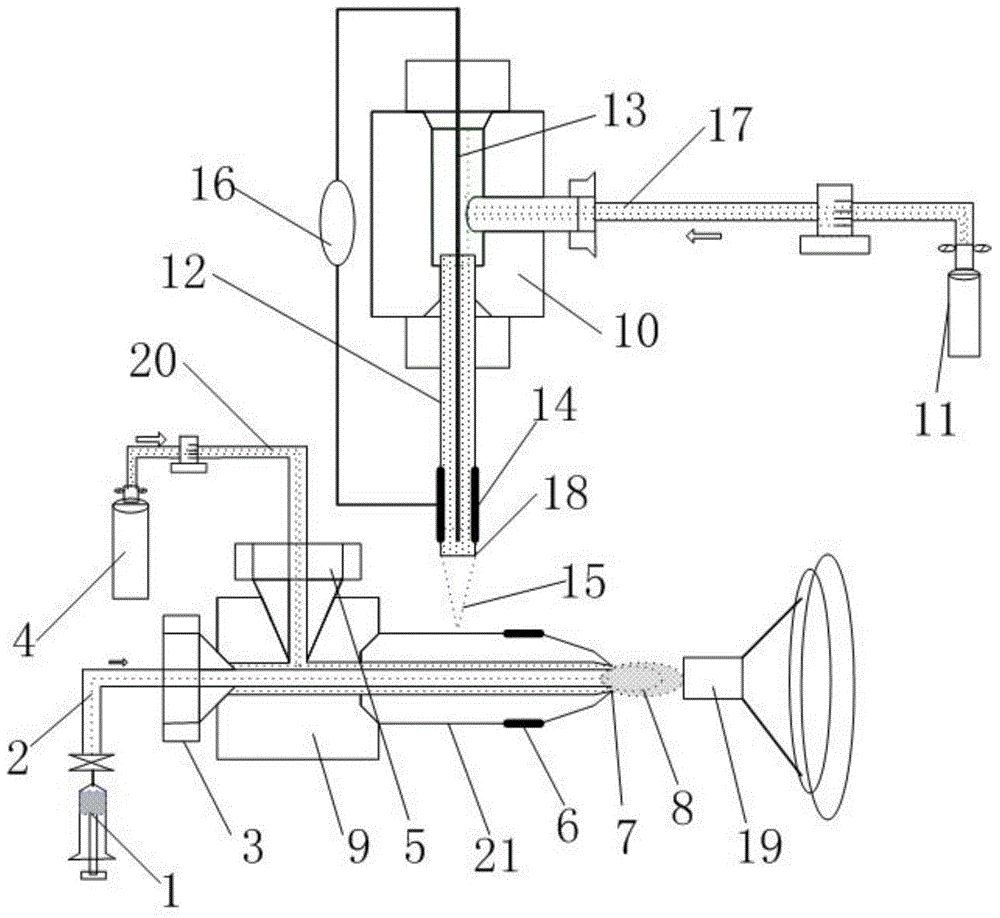

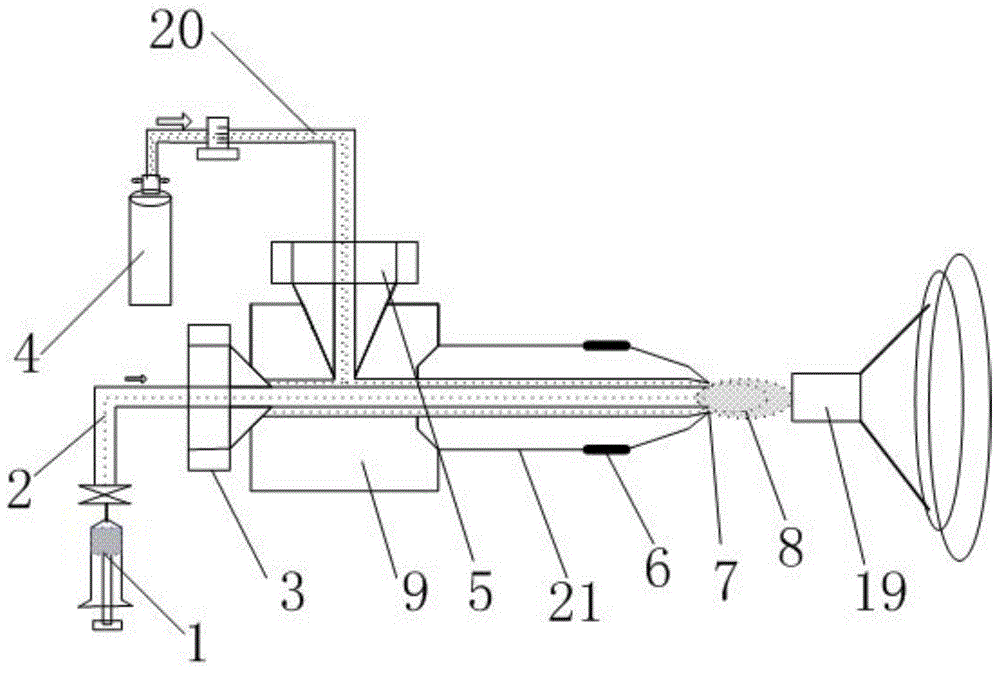

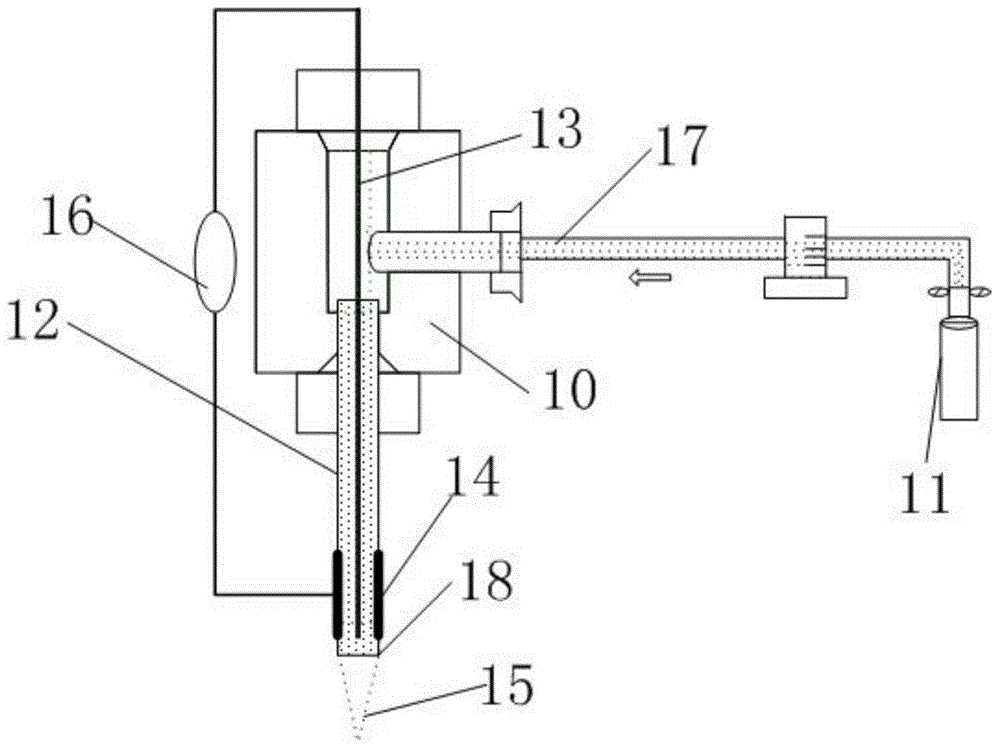

[0038] This embodiment provides a plasma spray mass spectrometry ionization source, the structure of the ionization source is as follows Figure 1-Figure 3 As shown, it includes a sampling device and a low-temperature plasma jet device.

[0039] Such as figure 2 As shown, the sampling device includes a sampling tube, a tee fitting 9 connected with the sampling tube, and a heating device 6, and the heating device 6 is coated on the outside of the tee fitting 9 for heating liquid samples. Specifically, the heating device 6 is an electric heating wire, and the outer layer is wrapped with thermal insulation cotton; the nozzle 7 of the metal nozzle 21 of the three-way pipe fitting 9 is located directly in front of the mass spectrometer port 19, and the distance between the two ports is 5mm.

[0040] Wherein the sampling tube comprises a liquid sampling tube 2 and a gas sampling tube 20; the nozzle 7 of the three-way pipe fitting 9 is a liquid outlet, and is provided with an inwar...

Embodiment 2

[0049] This embodiment provides a plasma spray mass spectrometry ionization source, the structure of the ionization source is as follows Figure 1-Figure 3 As shown, it includes a sampling device and a low-temperature plasma jet device.

[0050] Such as figure 2 As shown, the sampling device includes a sampling tube, a tee pipe fitting 9 communicated with the sampling tube, and a heating device 6. Specifically, the heating device 6 is an electric heating wire, and the outer layer is wrapped with thermal insulation cotton; The heating device 6 is coated on the outside of the three-way pipe fitting 9, and is used for desolventizing the heated liquid sample. The nozzle 7 of the metal nozzle 21 of the three-way pipe fitting 9 is located directly in front of the mass spectrometer port 19, and the distance between the two ports is 3mm.

[0051] Wherein the sampling tube comprises a liquid sampling liquid sampling tube 2, a gas sampling tube 4 and a heating device 6 three-way pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com