Electric fuse structure and formation method thereof

An electric fuse and fuse technology, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of inability to improve the fusing capacity of metal electric fuses, process capacity limitations, etc., to save chip area, low programming voltage, The effect of flexible settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the prior art, due to the limitation of process capability, an electric fuse with a smaller width cannot be obtained, so that the electric fuse is difficult to blow.

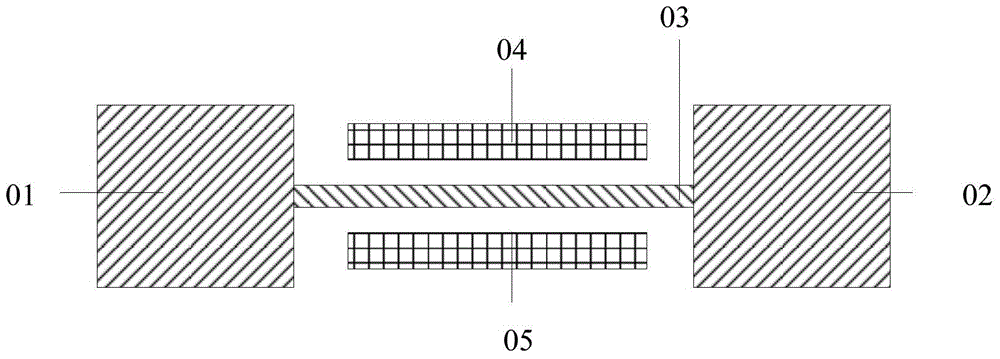

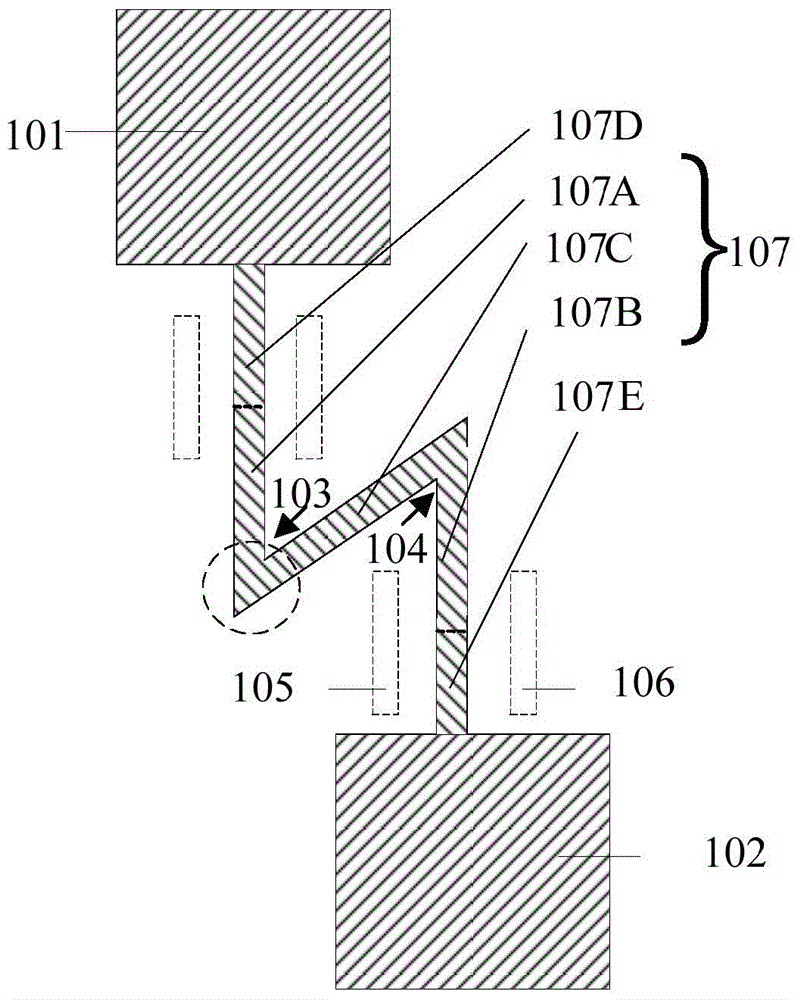

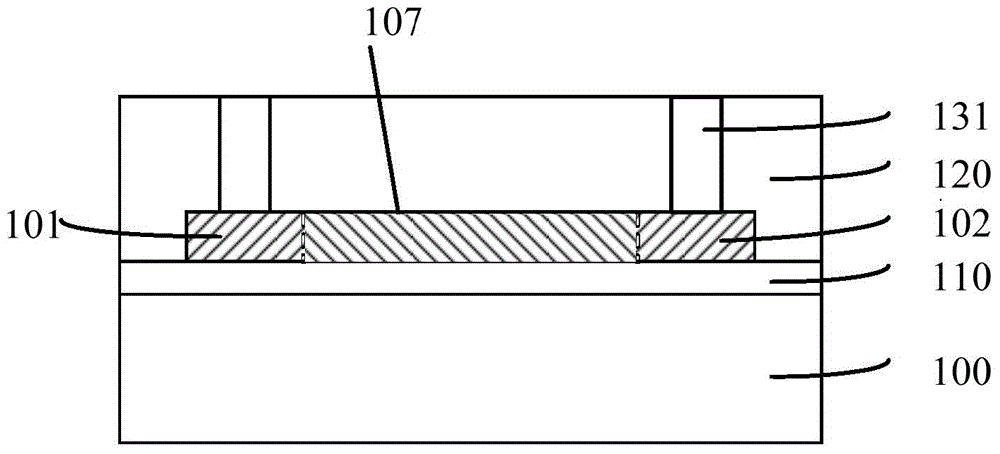

[0040]The present invention provides an electric fuse structure and its forming method. The electric fuse includes a first electrode, a second electrode, and a connection fuse connected to the first electrode and the second electrode; the connection fuse has at least A folded structure. The connection fuse at the corner will produce a current crowding effect, and the current density is greater than other parts of the electric fuse, which is beneficial to the self-heating effect of the electric fuse, making it easier to fuse at the toothed corner, and helping to reduce the electric fuse the programming voltage.

[0041] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com