High speed nano two-end nonvolatile storage and manufacturing method thereof

A non-volatile memory technology, applied in nanotechnology, nanotechnology, nanotechnology for information processing, etc., can solve the problem of large size, long read/write time and preparation process of nano field effect tube memory, difficult threshold Problems such as voltage drift, to improve the effect of large memory size, fast read/write speed, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

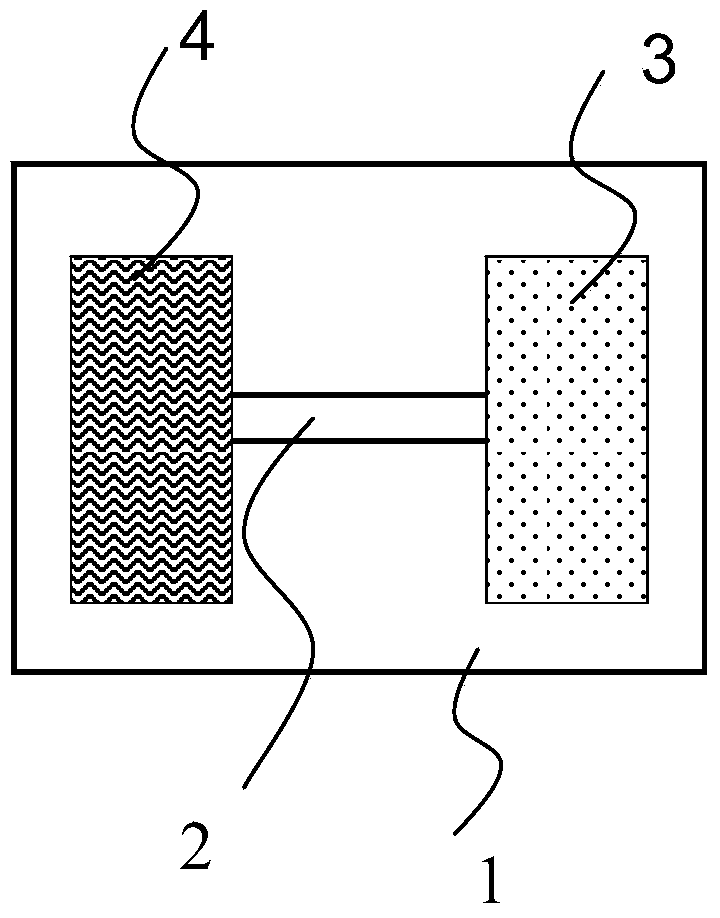

[0031] In this embodiment, Cu-doped p-type ZnS nanobelts are used as p-type doped one-dimensional nanomaterials 2, Cu electrodes are used as metal electrodes 4, and silicon wafers with a thickness of 300 nm on the surface are used as insulating substrates. 1. A p-type ZnS nanoribbon / Cu electrode high-speed non-volatile memory with both ends was prepared. The specific steps are as follows:

[0032] (1) At room temperature, after ultrasonically cleaning the silicon wafer with a thickness of 300nm on the surface of silicon oxide, alcohol is used as the dispersion liquid, and the p-type doped ZnS nanoribbons synthesized by chemical vapor phase are added to the dispersion liquid, and the nanobelts are ultrasonically oscillated. The ribbon is evenly suspended in the dispersion; and the dispersion containing the ZnS nanoribbon is spin-coated on a clean long silicon wafer with a silicon oxide layer;

[0033] (2) Spin-coat photoresist on the silicon wafer coated with ZnS nanoribbons, a...

Embodiment 2

[0039] In this example, p-type ZnS nanobelts were prepared by using Ag-doped p-type ZnS nanobelts as p-type doped one-dimensional nanomaterials 2, using Ag electrodes as metal electrodes 4, and using quartz glass as insulating substrate 1. / Ag electrode high-speed non-volatile memory at both ends, the specific steps are as follows:

[0040] (1) At room temperature, after the quartz glass is ultrasonically cleaned, alcohol is used as a dispersion liquid, and p-type doped ZnS nanobelts synthesized by chemical vapor phase are added to the dispersion liquid, and the nanobelts are evenly suspended in the dispersion liquid by ultrasonic vibration; and Spin-coat the dispersion containing ZnS nanobelts on clean quartz glass;

[0041] (2) Spin-coat photoresist on the silicon wafer coated with ZnS nanoribbons, and photoetch the electrode pattern of the metal electrode 4;

[0042](3) A layer of Ag electrode is prepared in the electrode pattern area of the photolithographic metal elect...

Embodiment 3

[0047] In this embodiment, the Ag-doped p-type ZnSe nanobelt is used as the p-type doped one-dimensional nanomaterial 2, the Cu electrode is used as the metal electrode 4, and the silicon wafer with a thickness of 300 nm on the surface is used as the insulating substrate. Bottom 1, a p-type ZnSe nanoribbon / Cu electrode high-speed non-volatile memory with both ends was prepared. The specific steps are as follows:

[0048] (1) At room temperature, after ultrasonically cleaning the silicon wafer with a thickness of 300nm on the surface of silicon nitride, alcohol was used as the dispersion liquid, and the p-type doped ZnSe nanoribbons synthesized by chemical vapor phase were added to the dispersion liquid, and ultrasonic vibration was used to make Nanobelts are uniformly suspended in the dispersion; and the dispersion containing ZnSe nanobelts is spin-coated on a clean silicon wafer with silicon oxide;

[0049] (2) Spin-coat photoresist on the silicon wafer coated with ZnSe nanor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com