Production method of algae iodate salt

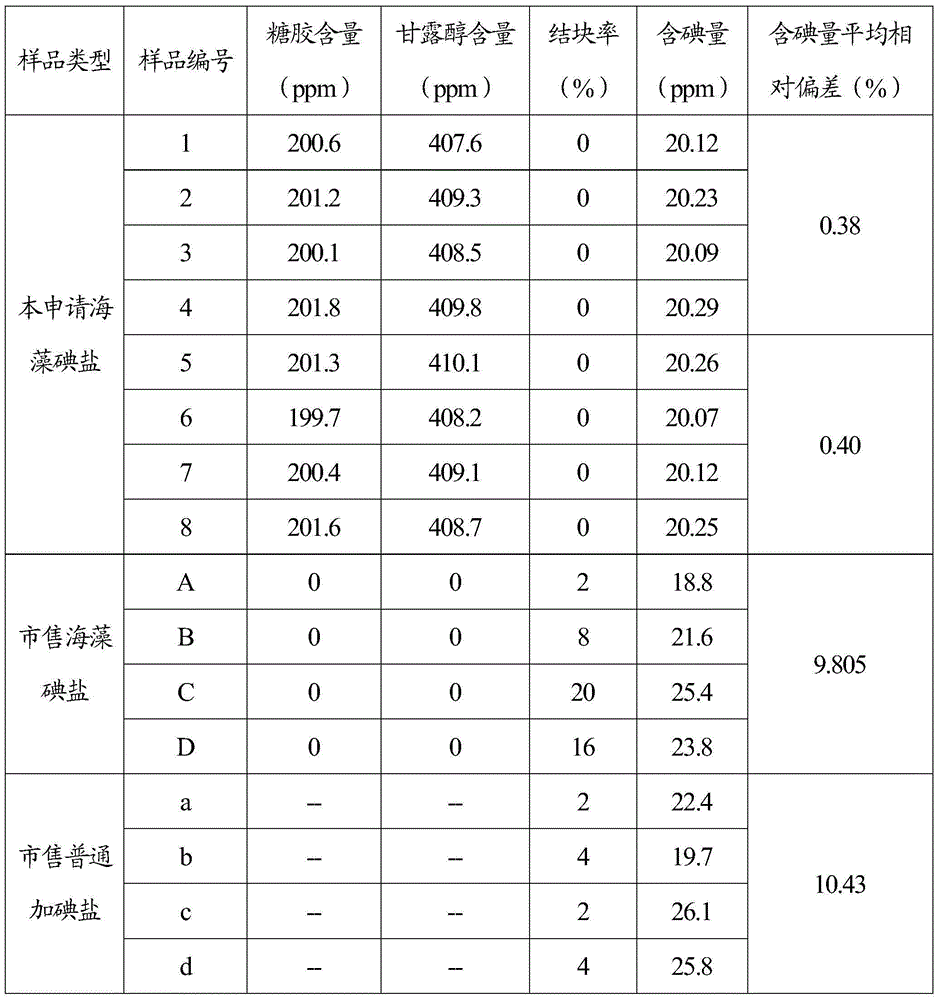

A seaweed iodized salt and production method technology, applied in the field of edible salt production, can solve the problems of uneven distribution of iodine element, uneven size of salt grains, and large difference in surface area, so as to achieve easy control of iodine addition and relative salt grain size Uniform, particle uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

[0028] A production method of seaweed iodized salt, comprising the following steps:

[0029] (1) Screening of raw material salt: Screen non-iodine raw material salt with a particle size grading sieve. Well mine salt, the weight percentage of NaCl in the well mine salt is greater than 99%, and the anticaking agent is ferric ammonium citrate;

[0030] (2) Preparation of iodine mother salt: get the non-iodine raw material salt of any particle size in step (1), by weight percentage, take out 2% of the non-iodine raw material salt of described particle size again, add seaweed concentrate, stir , to obtain iodine mother salt, the content of iodine element in the seaweed concentrate is 5g / L; the weight percent of organic iodine in total iodine is greater than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com