Cyclodextrin super-molecular micro-capsule and preparation method thereof

A cyclodextrin and supramolecular technology, applied in the field of microcapsule production, can solve the problems of complicated process, organic solvent residue, low encapsulation efficiency, etc., and achieve the effects of good sustained release effect, favorable release and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

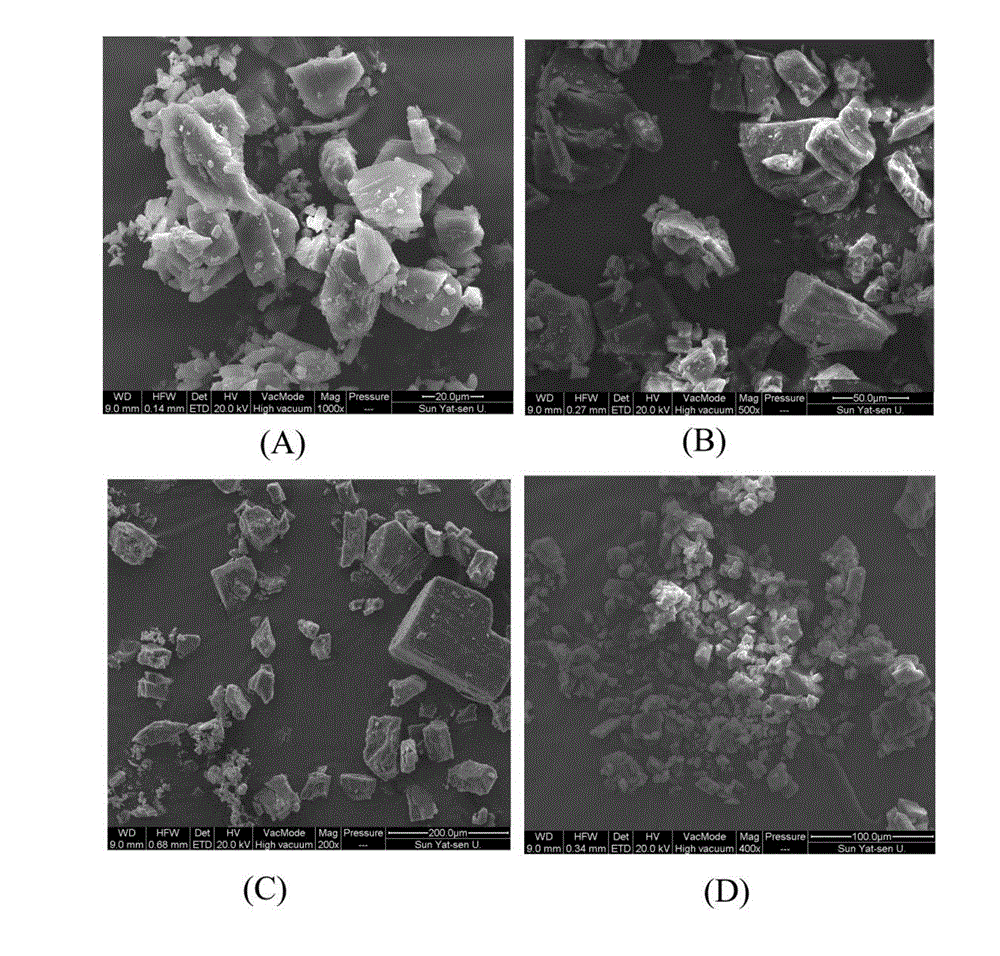

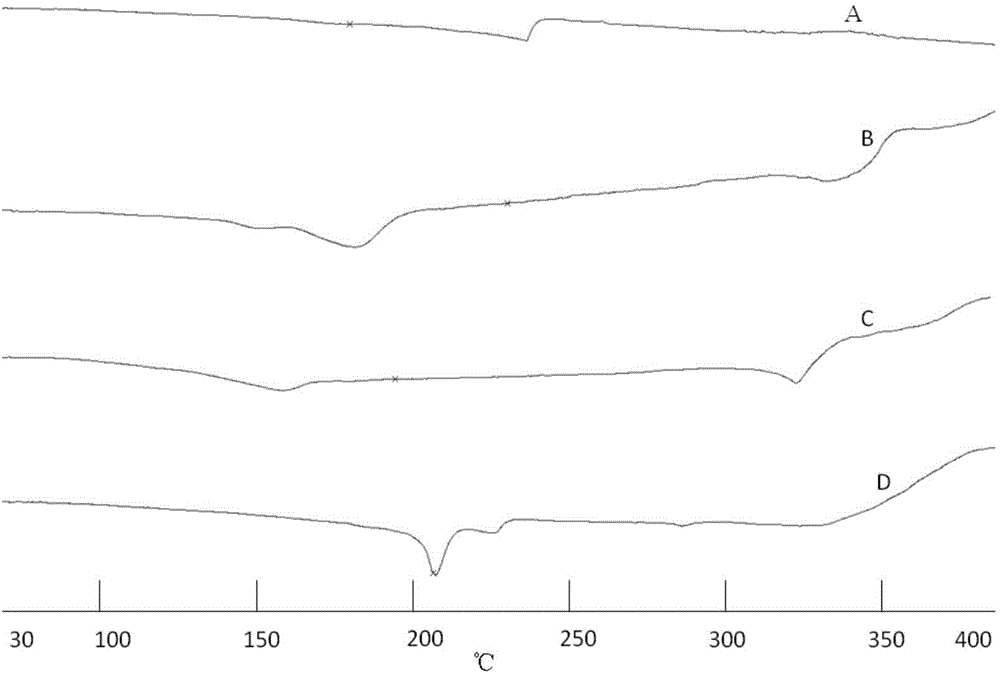

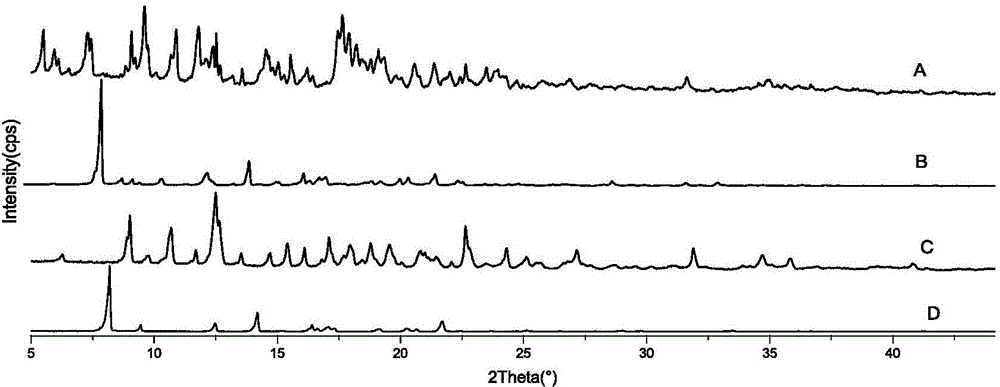

[0032] Weigh 1.56g of menthol and 15.6g of β-cyclodextrin in a 500ml stoppered round-bottom flask for mixing, then pour it into a filter paper tube, put the filter paper tube into a 1L reaction kettle, and add 50ml of water to the reaction kettle As a co-solvent, heat the reactor so that its temperature is between 30-100°C, and feed about 1kg of CO into the reactor 2 gas, make the kettle pressure between 8-10MPa, keep it for 24h, release the pressure within 10min, take out the filter paper tube, and vacuum dry it at 20-50℃ to get cyclodextrin supramolecular microcapsules, and measure the encapsulation The rate is 56.85%. The instrumental analysis spectrum of the cyclodextrin supramolecular microcapsules formed by it is as attached Figure 1-2 shown;

[0033] The measuring method of specific encapsulation efficiency is as follows:

[0034] Encapsulation efficiency is an important index to measure the preparation process of supramolecular microcapsules. The encapsulation effici...

Embodiment 2

[0044] Weigh 0.19g of angelica oil and 15.6g of β-cyclodextrin in a 500ml stoppered round-bottomed flask for mixing, then pour it into a filter paper tube, put the filter paper tube into a 1L reaction kettle, and add 200ml of water to the reaction kettle As a co-solvent, feed about 1 kg of CO into the kettle 2 Gas, so that the temperature in the reactor is 30-80 ° C, the pressure is 30-40 MPa, after keeping for 0.5 hours, the pressure is released within 1-60 minutes, the filter paper tube is taken out, and after drying, the supramolecular microcapsules of volatile oil are obtained. The encapsulation rate was 85.37%. The encapsulation rate was measured with artebenolactone as an index component. The method for measuring the encapsulation rate was the same as in Example 1.

Embodiment 3

[0046] Weigh 1.48g of star anise oil and 15.6g of β-cyclodextrin in a 500ml stoppered round bottom flask to mix well, then pour it into a filter paper tube, put the filter paper tube into a 1L reaction kettle, and add 10ml of Water is used as a co-solvent, and about 1kg of CO is introduced into the kettle 2 gas, so that the temperature in the reactor is 60°C and the pressure is 35MPa. After keeping it for 8 hours, the pressure is released within 1-60min. The encapsulation rate was 88.25%. The encapsulation rate was measured with anethole as an index component. The method for measuring the encapsulation rate was the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com