Preparation method of oxidized-graphene-modified silica gel chromatography filling material

A technology of silica gel chromatography and graphene, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of uncontrollable graphene oxide content and achieve excellent chromatographic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

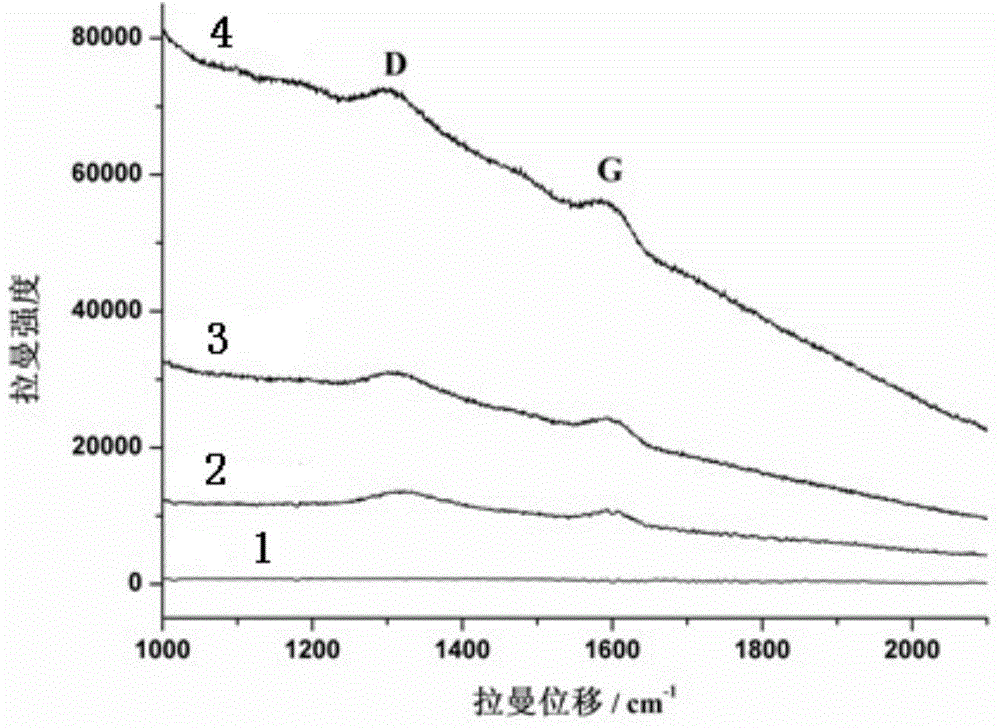

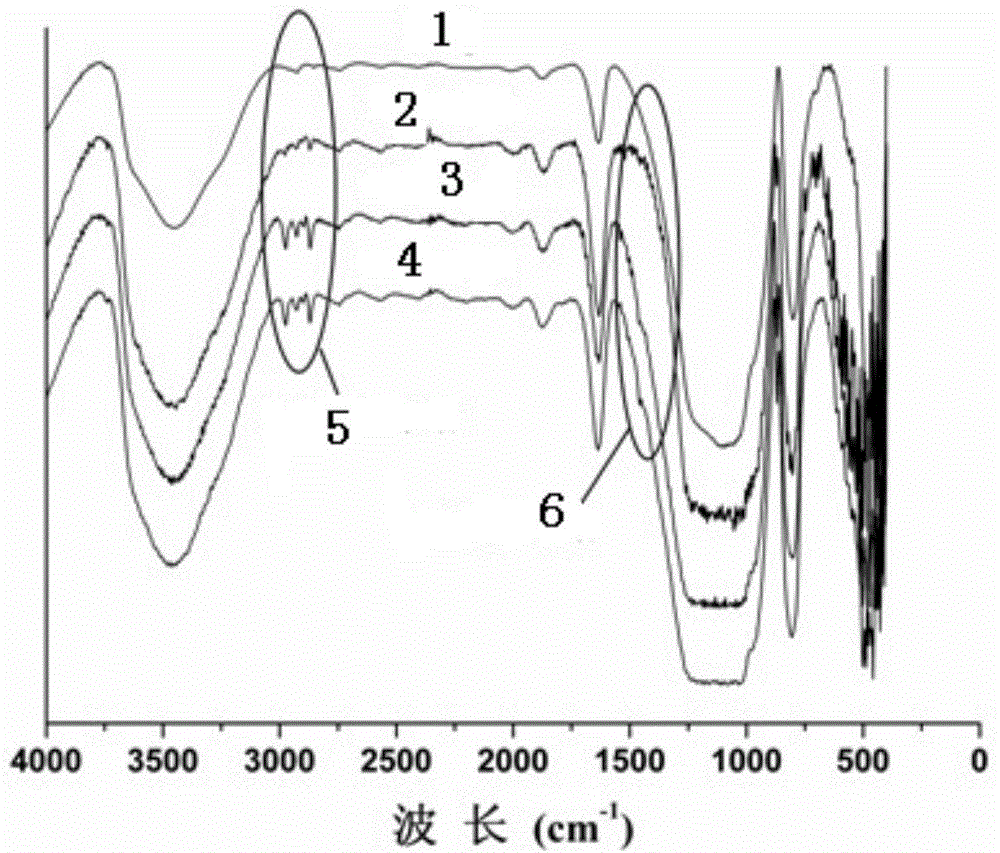

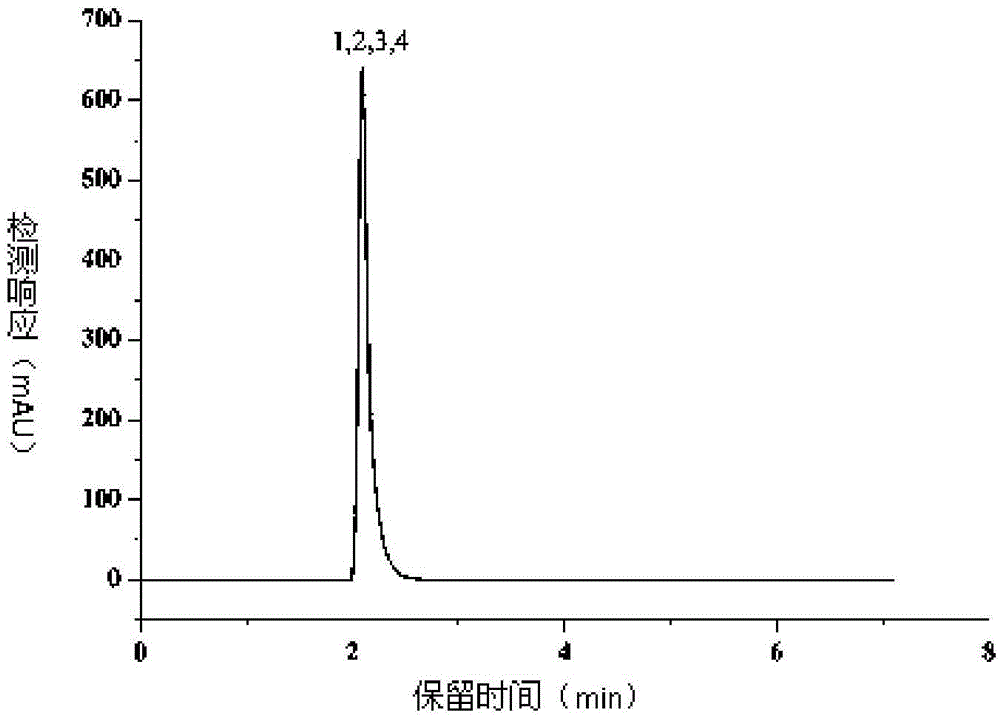

[0054] Preparation of Graphene Oxide Modified Silica Gel Chromatography Packing

[0055] Steps:

[0056] ① Put 10g of silica gel and 100mL of hydrochloric acid with a mass fraction of 37% into a reflux condensing device, heat and reflux at 110°C for 4h, then separate the silica gel, wash it with distilled water until neutral, and finally dry it in vacuum at 120°C for 6h to obtain the surface 10g of silica gel containing silanol;

[0057] ②Weigh 0.15g graphene oxide and add it into 100mL distilled water for 2h, centrifuge for 20min to obtain 1.5mg / mL yellowish-brown clear and transparent graphene oxide suspension;

[0058] ③Add 10g of silica gel pellets containing silanol on the surface prepared in step ① to 100g of the graphene oxide suspension prepared in step ②, sonicate for 20min, stir for 2h, wash with distilled water, and then vacuum dry at 60°C for 7h , to obtain micron-scale light gray GO / SiO 2 Small balls 10g;

[0059] ④The above-prepared GO / SiO 2 The pellets were...

Embodiment 2

[0062] Preparation of Graphene Oxide Modified Silica Gel Chromatography Packing

[0063] Steps:

[0064] ① Put 8g of silica gel and 80mL of hydrochloric acid with a mass fraction of 37% into a reflux condensing device, heat and reflux at 100°C for 5h, then separate the silica gel, wash it with distilled water until neutral, and finally dry it in vacuum at 120°C for 7h to obtain the surface Silica gel containing silanol 8g;

[0065] ② Weigh 0.08g graphene oxide and add it into 80mL distilled water for 2h, centrifuge for 20min to obtain 1mg / mL yellowish brown clear and transparent graphene oxide suspension;

[0066] ③ Add 8 g of silica gel pellets containing silanol produced in step ① to 80 g of the graphene oxide suspension prepared in step ②, sonicate for 25 minutes, stir for 3 hours, wash with distilled water, and then vacuum-dry at 70°C for 6 hours. Get micron-scale light gray GO / SiO 2 Small balls 8g;

[0067] ④The above-prepared GO / SiO 2 The microspheres were calcined ...

Embodiment 3

[0070] Preparation of Graphene Oxide Modified Silica Gel Chromatography Packing

[0071] Operation steps: ① Put 15g of silica gel and 150mL of hydrochloric acid with a mass fraction of 37% into a reflux condensing device, heat and reflux at 100°C for 5h, then separate the silica gel, wash it with water until neutral, and finally dry it in vacuum at 120°C for 7h. Obtain 15 g of silica gel containing silanol on the surface;

[0072] ② Weigh 0.15g of graphene oxide and add it to 150mL of distilled water, sonicate for 1.5h, and centrifuge for 20min to obtain a 1mg / mL yellow-brown, clear and transparent graphene oxide suspension;

[0073] ③Add 15g of silica gel pellets containing silanol on the surface prepared in step ① to 150g of the graphene oxide suspension prepared in step ②, stir for 4 hours after ultrasonication for 25 minutes, wash with distilled water, and then vacuum dry at 60°C for 8 hours , to obtain micron-scale light gray GO / SiO 2 Small balls 15g;

[0074] ④The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com