Three-degree-of-freedom parallel mechanism and machine tool adopting same

A degree of freedom and parallel technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the obstacles to the development of five-axis linkage CNC machine tools with parallel mechanism spindle head, less configuration of parallel mechanism spindle head, high assembly accuracy requirements, etc. problems, to achieve the effect of easy high-speed movement, small mass of moving parts, and strong load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure, principle and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

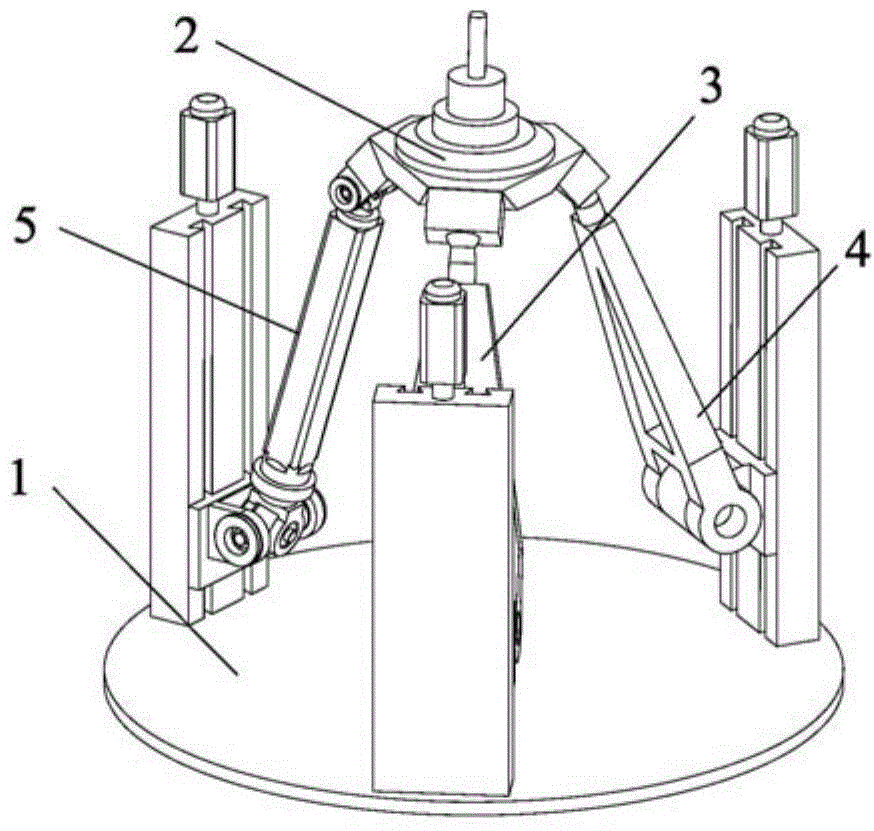

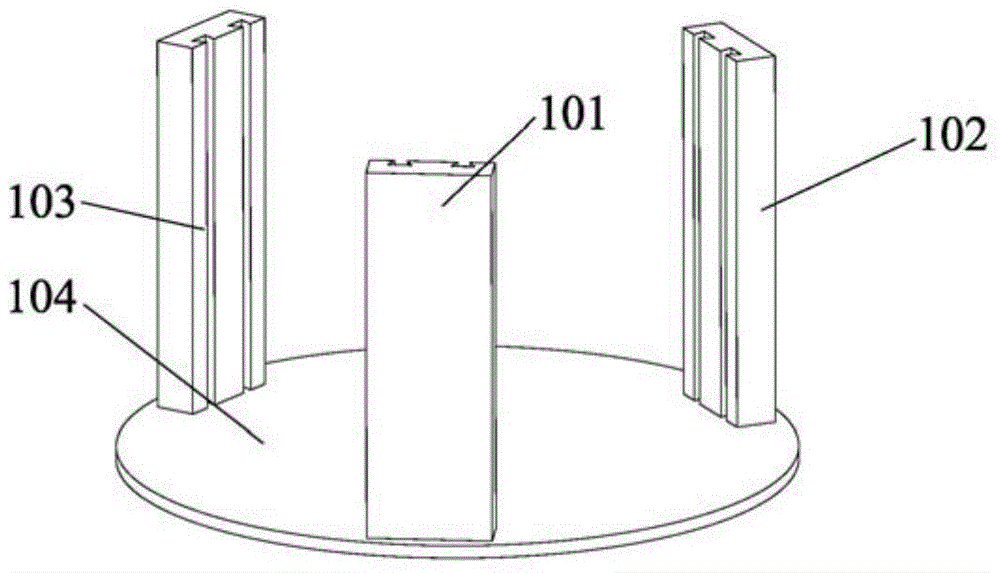

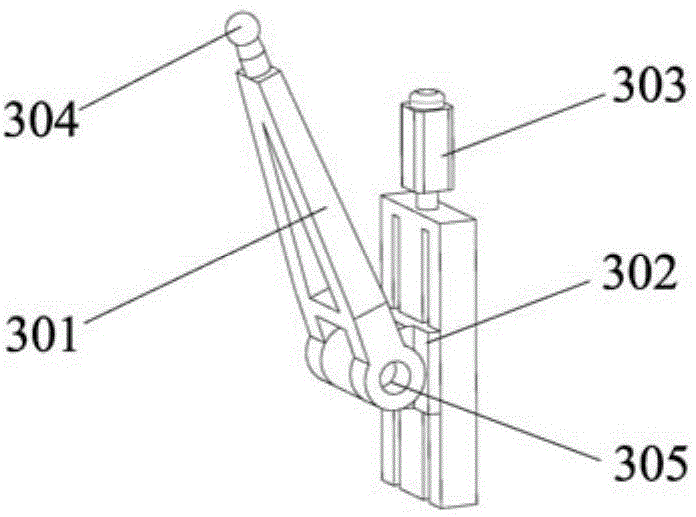

[0020] figure 1 The three-dimensional structural schematic diagram of the embodiment of the three-degree-of-freedom parallel mechanism provided by the present invention, the three-degree-of-freedom parallel mechanism includes a fixed platform 1, a moving platform 2, a first branch 3, a second branch 4 and a third branch 5; the fixed platform 1 passes through The coordinated movement of the first branch 3 , the second branch 4 and the third branch 5 realizes the three-degree-of-freedom movement of the moving platform 2 . figure 2 It is a structural schematic diagram of an embodiment of the fixed platform of the present invention. The fixed platform 1 includes a first frame 101, a second frame 102, a third frame 103 and a base 104, and the three frames are arranged and fixed at the vertices of an equilateral triang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com