Vertical type continuous band steel surface scale cleaning line

A surface cleaning and oxide skin technology, which is applied in the direction of workpiece surface treatment equipment, other manufacturing equipment/tools, metal rolling, etc., can solve the problems of large dust, polluting the environment, poor cleaning effect, etc., to meet the process requirements, cleaning The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

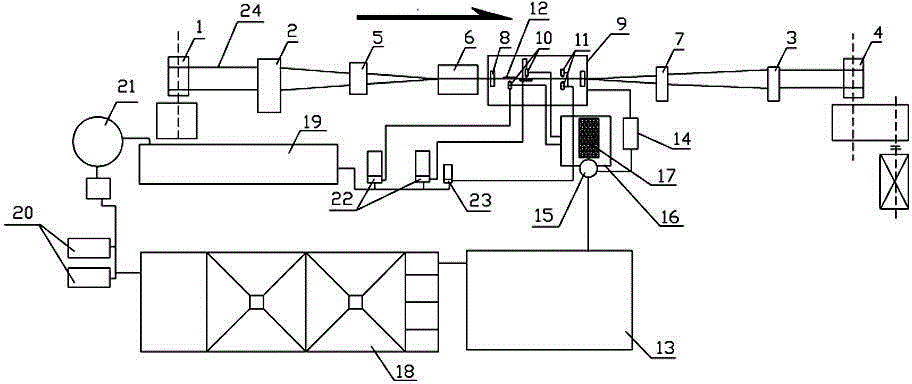

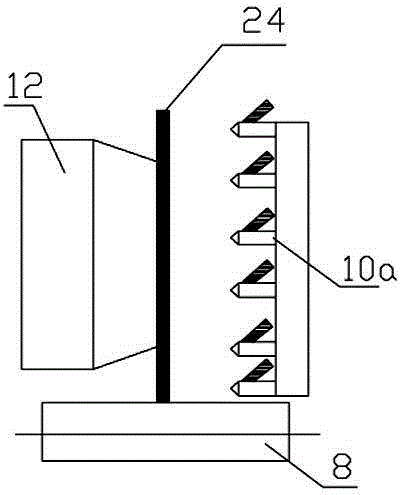

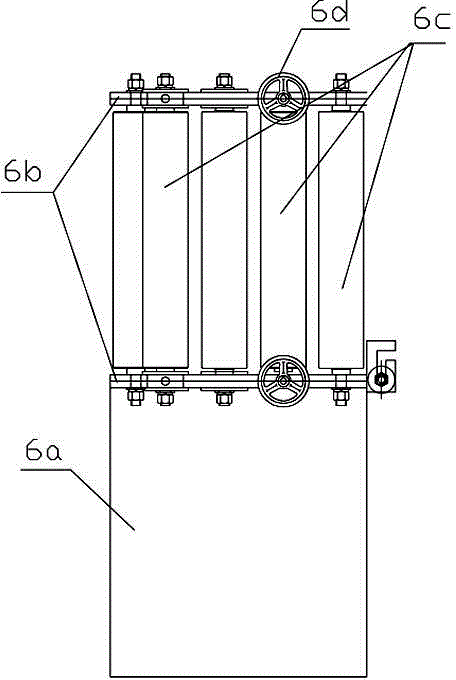

[0017] Such as figure 1 As shown in the present invention, the vertical strip steel surface scale continuous cleaning production line of the present invention includes a strip steel uncoiler 1, a welding machine 2, a strip steel surface cleaning device, a three-roller tension roll leveler 3 and a strip steel strip that are arranged in sequence. Winder 4, in order to change the horizontally placed strip into vertical placement, a strip vertical turning machine 5 is also arranged successively between the welding machine 2 and the strip surface cleaning device (the horizontal strip can be turned over 45 °, and then erected) and strip vertical leveler 6; between the strip surface cleaning device and the three-roller tension roller leveler 3, a strip horizontal turning machine 7 is arranged, which can turn the cleaned up vertical The strip steel in the state is first turned over 45 ° and then placed horizontally; in order to ensure the cleaning effect, the strip steel surface clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com