Method for separating and purifying N-acetylneuraminic acid produced by microbiological fermentation

A technology of acetylneuraminic acid and microbial fermentation, which is applied in the direction of sugar derivatives, sugar derivatives, sugar derivatives preparation, etc., can solve the problems of high price and high quality demand, reduce pressure, improve purity, and improve product quality. The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

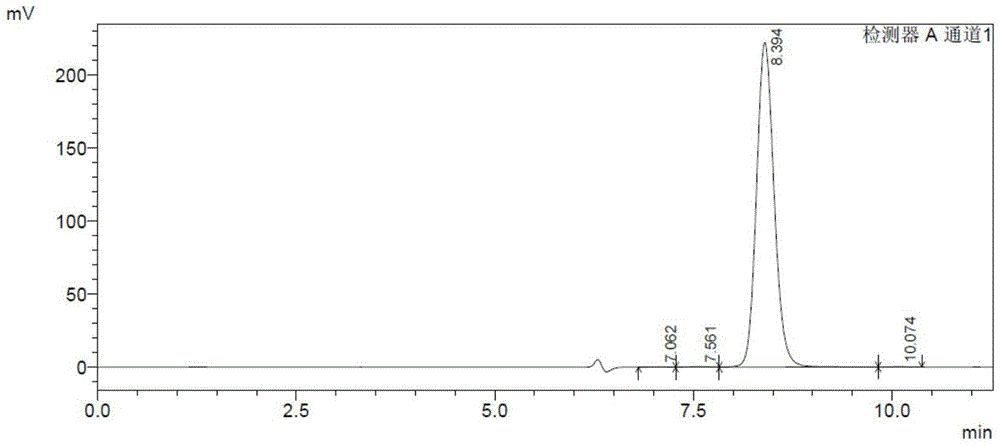

Image

Examples

Embodiment 1

[0032] In this implementation, the N-acetylneuraminic acid produced by microbial fermentation is separated and purified according to the following steps:

[0033] a. Separation of bacterial liquid: In the method disclosed in the invention patent with application number 201310600843.0, the fermented liquid containing N-acetylneuraminic acid produced by the fermentation of E. The base montmorillonite powder is used for flocculation and sedimentation of the bacteria, and then the filter cloth is used to squeeze and filter the filter cloth with a pore size of 2000 meshes. Bacterial fermentation broth, detected by high performance liquid chromatography, the content of the target product N-acetylneuraminic acid in the fermentation broth has almost no change before and after sterilization, that is, the use of montmorillonite powder to flocculate the bacteria will not cause loss of N-acetylneuraminic acid ;

[0034] b. Removal of impurity proteins: adding hydrochloric acid to the ste...

Embodiment 2

[0040] In this implementation, the N-acetylneuraminic acid produced by microbial fermentation is separated and purified according to the following steps:

[0041]a. Separation of bacterial liquid: In the method disclosed in the invention patent with application number 201310600843.0, the fermented liquid containing N-acetylneuraminic acid produced by the fermentation of E. The base montmorillonite powder is used for flocculation and sedimentation of the bacteria, and then the filter cloth is used to squeeze and filter the filter cloth with a pore size of 2000 meshes. Bacterial fermentation liquid;

[0042] b. Removal of impurity proteins: adding hydrochloric acid to the sterilizing fermentation broth, adjusting the pH to 3.8, heating at 90°C for 0.5h to precipitate the impurity proteins, centrifuging, removing the impurity protein precipitation, and obtaining the protein-removing fermentation broth;

[0043] c. Decolorization: adding activated carbon accounting for 3% of the ...

Embodiment 3

[0048] In this example, the same raw material as in Example 2 is separated and purified in the same manner as in Example 2, the only difference being that the temperature in step b is changed from 90°C to 70°C, and the purity of the final product in this implementation is 97.9% after testing. Compared with Example 2, it is worse. It shows that the effect of heat treatment at 90°C is better, it can completely denature the protein in the fermentation liquid, reduce the impurity protein in the crystallization liquid, and improve the purity of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com