Crystalline silicon growth device

A growth device, crystal silicon technology, applied in crystal growth, post-processing device, after treatment, etc., can solve the problems of heater difference, large influence of heat conduction, temperature control precision cross, etc., to achieve slow and uniform heat dissipation, air pumping Easy to filter and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

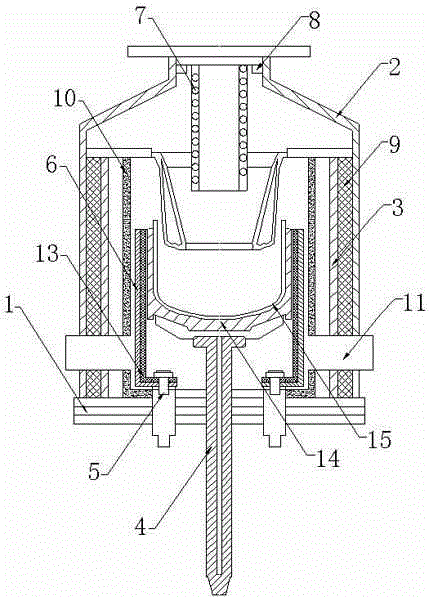

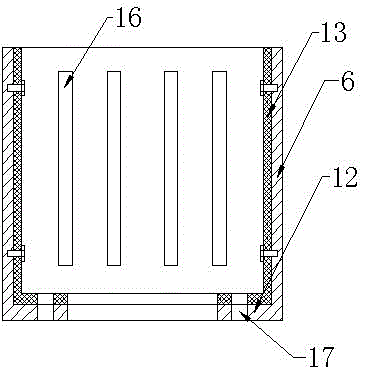

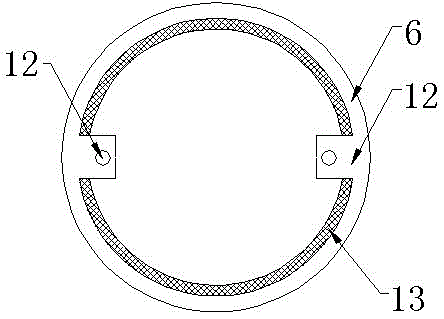

[0021] Such as figure 1 Shown in -3, a kind of crystalline silicon growing device comprises fixed base 1, heat preservation outer barrel 2, heat preservation inner barrel 3, central shaft supporting rod 4, heating electrode 5, heater 6 and water cooling device 7, described heat preservation outer A clasp 8 is arranged on the inner side of the upper port of the bucket 2, the water cooling device 7 is stuck on the clasp 8, the heat preservation inner barrel 3 is arranged inside the heat preservation outer barrel 2, and the heat preservation inner barrel 3 is connected with the heat preservation A graphite felt layer 9 is filled between the outer barrels 2, and a heat insulating layer 10 is arranged inside the heat-insulating inner barrel 3, and a certain distance is set between the heat-insulating layer 10 and the heat-insulating inner barrel 3. An evacuation hole 11 is provided on the side wall of the thermal insulation outer barrel 2. The evacuation hole 11 communicates with t...

Embodiment 2

[0024] Such as figure 1 Shown in -3, a kind of crystalline silicon growing device comprises fixed base 1, heat preservation outer barrel 2, heat preservation inner barrel 3, central shaft supporting rod 4, heating electrode 5, heater 6 and water cooling device 7, described heat preservation outer A clasp 8 is arranged on the inner side of the upper port of the bucket 2, the water cooling device 7 is stuck on the clasp 8, the heat preservation inner barrel 3 is arranged inside the heat preservation outer barrel 2, and the heat preservation inner barrel 3 is connected with the heat preservation A graphite felt layer 9 is filled between the outer barrels 2, and a heat insulating layer 10 is arranged inside the heat-insulating inner barrel 3, and a certain distance is set between the heat-insulating layer 10 and the heat-insulating inner barrel 3. An evacuation hole 11 is provided on the side wall of the thermal insulation outer barrel 2. The evacuation hole 11 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com