Eccentric type biomass fuel feeder

A biomass fuel and feeder technology, applied in fuel supply, combustion methods, combustion equipment, etc., can solve the problems of poor fuel adaptability, influence on boiler operation, unsuitable selection, etc., and achieve low manufacturing cost, good sealing, Overcoming the effect of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

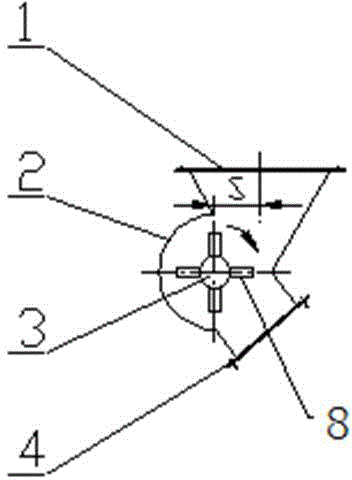

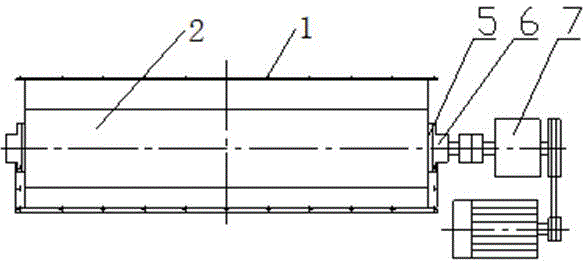

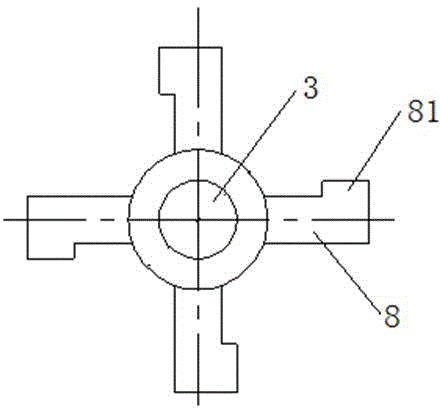

[0023] like figure 1 , 2 As shown, the offset biomass fuel feeder of the present invention includes a casing 2, the casing 2 includes a semicircular arc plate and two end plates, and an upper flange 1 is arranged above the casing 2 , the lower part of the shell 2 is provided with a lower flange 4, and the shell 2 is provided with a feeding shaft 3, the center of the feeding shaft 3 coincides with the center of the semicircular arc plate, and the feeding shaft 3 Both ends of 3 are respectively fixed on the end plate through circular flanges 5, bearings 6 are arranged between the material-removing shaft 3 and the circular flange 5, and one end of the material-removing shaft 3 is connected to a geared motor drive mechanism 7; On the feeding shaft 3, a plurality of groups of feeding sheets 8 located on the same circumference are evenly distributed;

[0024] The center line of the upper square flange 1 is vertically arranged, the center line of the lower square flange 4 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com