Integrated series motor driving device

A technology of driving device and series motor, which is applied to electromechanical devices, electric components, electrical components, etc., can solve the problems that the motor cannot achieve high-speed operation, the motor starts and stops for a long time, and cannot meet industrial requirements. Cost, simple structure, the effect of reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

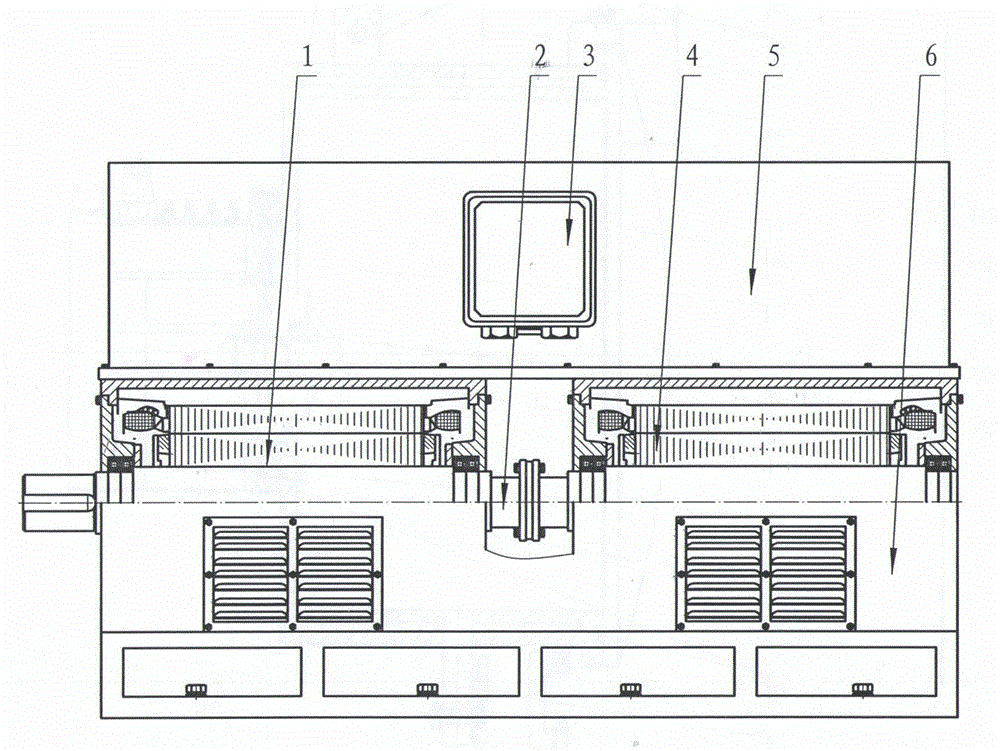

[0010] See figure 1 , including double-axis extension motor 1, coupling 2, junction box 3, motor 4, top cover 5, machine base 6, the aforementioned

[0011] There is a double-axis extension motor 1 on the left side of the upper housing of the machine base 6, a motor 4 is installed on the right side, and a top cover 5 is arranged above the machine base. 2 connection, the lead wires U, V, W of the winding stator of the double-axis extension motor 1 and the lead wires U, V, W of the winding stator of the motor 4 are merged together, and after the merger, they are connected to U, V, W on the junction box. The V and W terminals are correspondingly connected to the output terminals U, V and W of a frequency converter through cables, and are driven and operated by the frequency converter.

[0012] Due to the small rotor inertia, small outer diameter and low linear speed of the motor rotor of the integrated series motor drive device, the motor speed is greatly improved; at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com