Dynamic load fast response circuit

A fast-response, dynamic-load technology, applied to electrical components, adjusting electrical variables, instruments, etc., can solve problems such as response speed that needs to be improved, and achieve the effect of quick response and reduction of deviation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

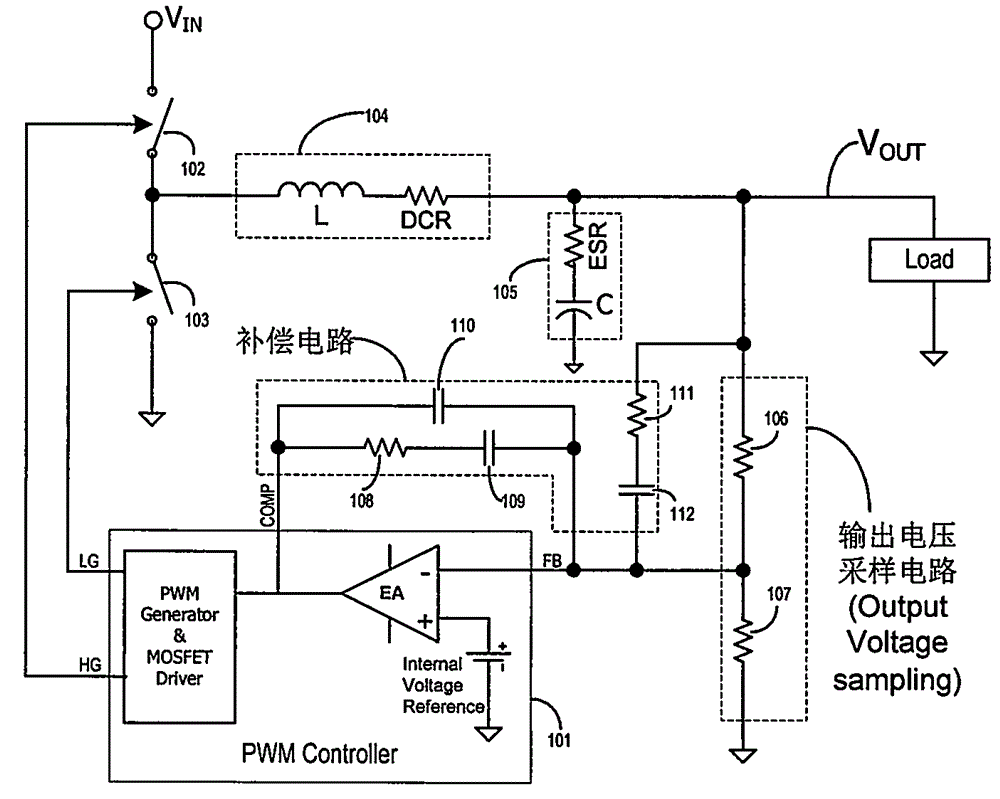

[0033] figure 1 It is a basic voltage-controlled Buck converter; 101 is a PWM control circuit, usually integrated with an error amplifier, a PWM generator, a MOSFET drive circuit, and other auxiliary function circuits such as a reference voltage source, soft start, oscillator, etc.; 102, 103 They are control switching tube and freewheeling switching tube, usually MOSFET; 104 is output filter inductor, which can be equivalent to ideal inductance and equivalent DC resistance in series; 105 is output filter capacitor, which can be equivalent to ideal capacitor and equivalent series Resistance composition; 106 and 107 are the voltage divider resistors for setting the output voltage, 106 is usually called the upper voltage divider resistor, and 107 is the lower voltage divider resistor; 108-112 and the internal error amplifier of the PWM controller form a compensation loop, which can be adjusted appropriately The compensation loop obtains Type-I, Type-II and Type-III control characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com