Overheating protection circuit and overheating protection method based on speed command voltage

A technology of speed command and overheating protection, which is applied in the direction of electrical components, motor control, electronic commutation motor control, etc., can solve the problems of complex circuit, unreceived, and good price, and achieve the effect of high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

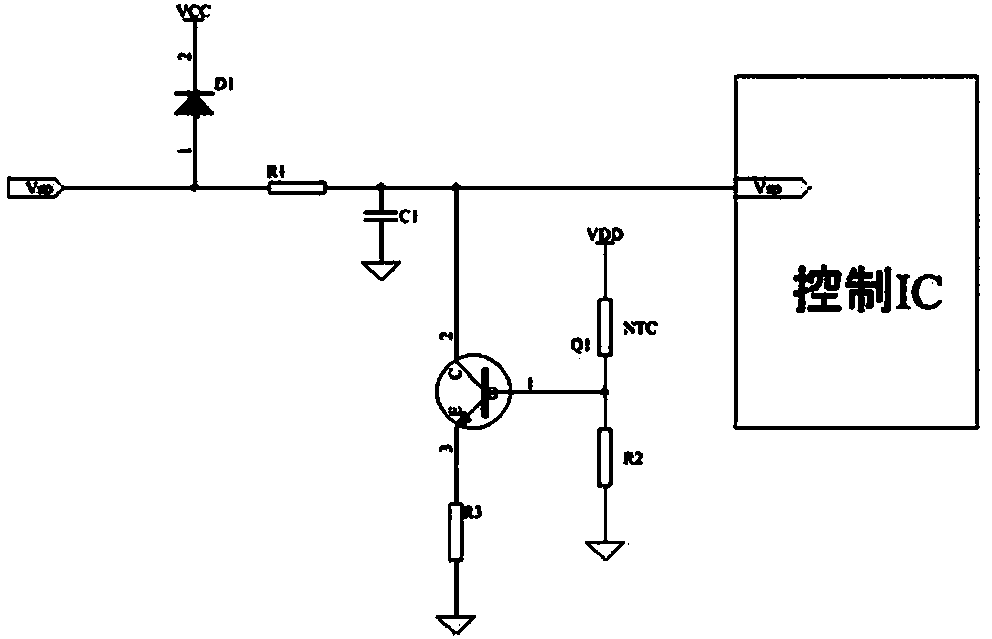

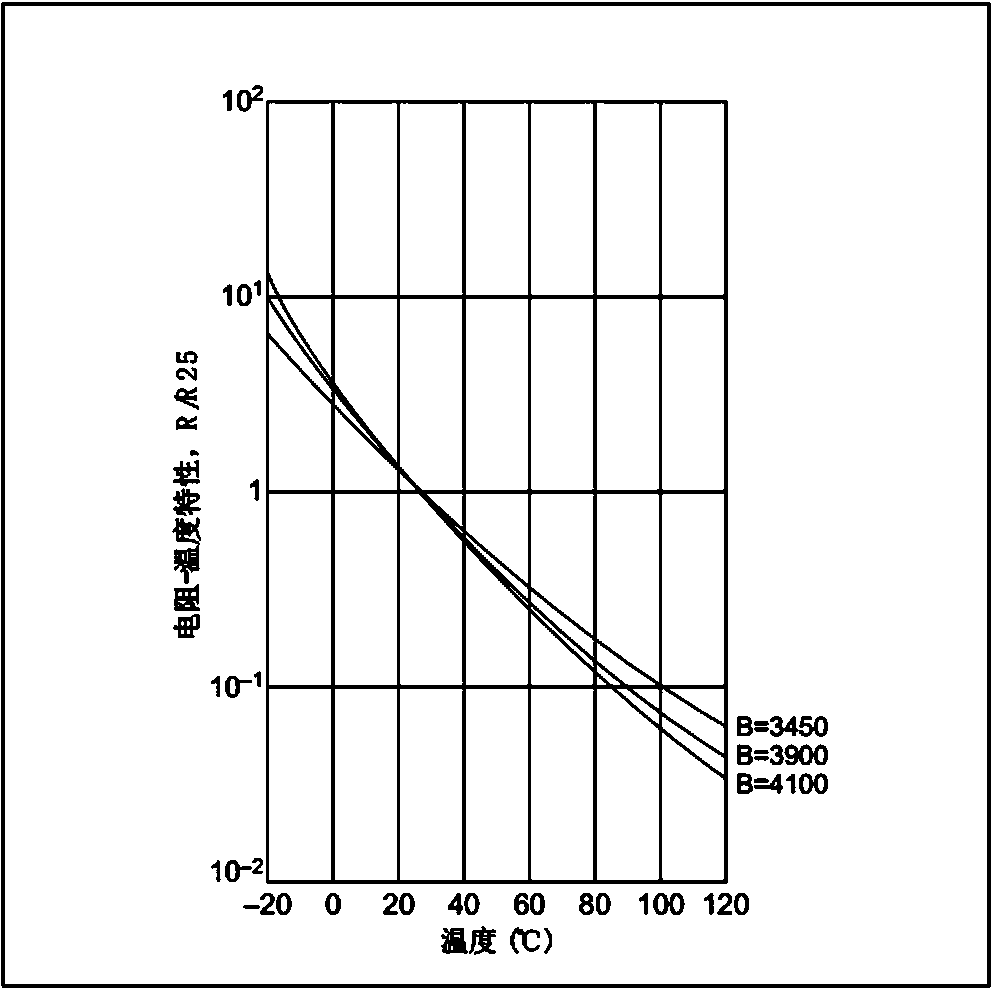

[0023] Please refer to Figure 1 to Figure 3 , the general voltage range of the speed command voltage Vsp is between 2.1V and 5.4. When the speed command voltage Vsp rises, the effective value of the motor terminal voltage increases, and the output power increases; when the speed command voltage Vsp decreases, the effective value of the motor terminal voltage decreases, the output power decreases. Adjusting the speed command voltage Vsp is the most effective way to control the conversion of the motor output power.

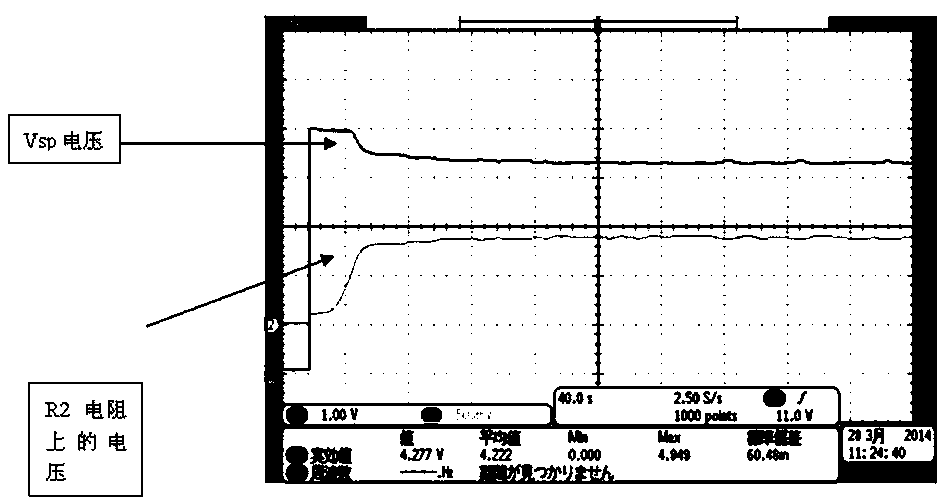

[0024] After the speed command voltage Vsp enters the motor, it first passes through a clamping diode D1 to filter out the large voltage surge to ensure that the speed command voltage Vsp is less than VCC+0.7V, and then the speed command voltage Vsp passes through a low-pass RC filter circuit to filter out High frequency small signal interference. 1.2KΩ and 0.02uF are recommended for this RC parameter. If the time constant is selected too large, there will be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com