Method for manufacturing discharge lamp electrode

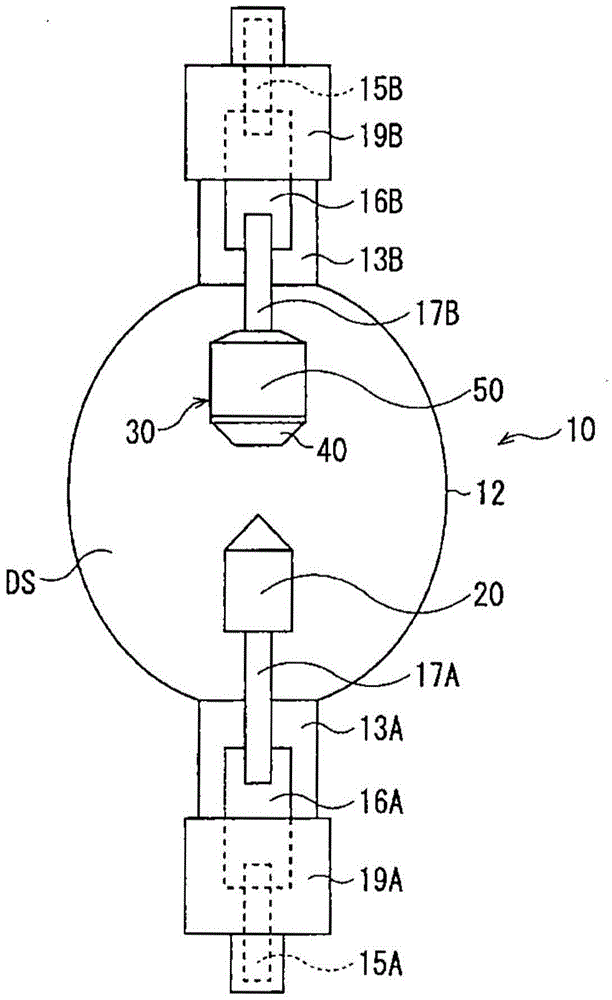

A manufacturing method and technology for discharge lamps, which are applied in the manufacture of discharge tubes/lamps, electrode systems, and thermionic cathodes, etc., can solve the problems of large joint surface application and electrode damage, and achieve the effect of excellent electrode performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

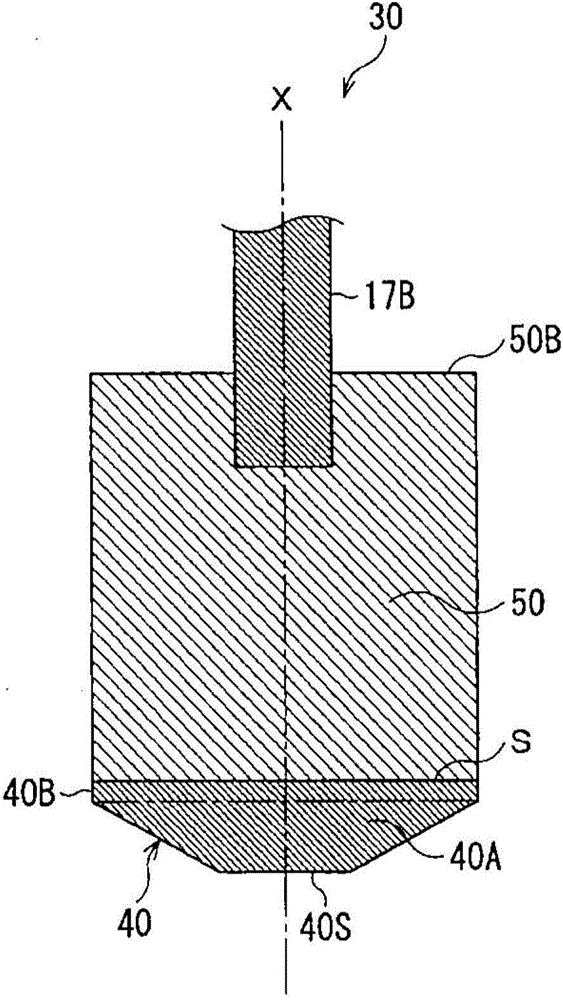

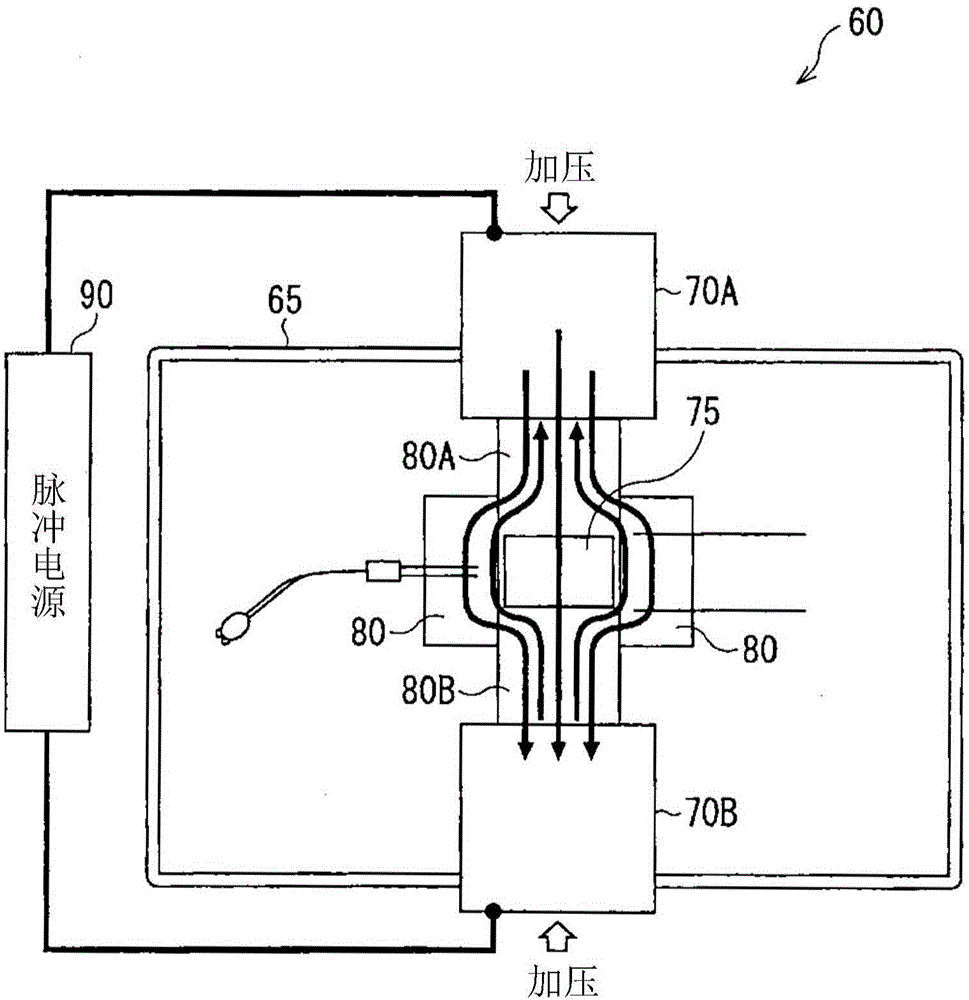

[0151] The discharge lamp of Example 1 corresponds to the discharge lamp of Embodiment 1. Regarding conditional expression (1), an anode in which a tip portion is a thoriated tungsten (thoriated tungsten) member and a main body portion is a pure tungsten member was manufactured by SPS bonding. At this time, the anodes of Examples 1 to 3 and Comparative Examples 1 to 3 were manufactured by changing the outer diameter L of the joining surface, the joining temperature T, the applied pressure P, and the joining time t. Then, a tensile test was performed on each of the manufactured anodes. Table 1 shows the experimental results.

[0152] [Table 1]

[0153]

[0154] Example 1 and Comparative Example 1 are electrodes manufactured by SPS-bonding a thoriated tungsten member and a pure tungsten member without intervening members. Example 2 and Comparative Example 2 are electrodes obtained by SPS bonding with a tantalum (Ta) member interposed therebetween as an insertion member. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com