Ti3C2Tx-TiO2 nanotube array self-supporting film electrode material as well as preparation method and application thereof

A self-supporting thin film, nanotube array technology, applied in nanotechnology, nanotechnology, battery electrodes, etc., can solve the problems of unfavorable large-scale application promotion, high requirements for personnel operation level, complex coating process, etc. The effect of fast transmission, abundant active sites, and simple process

Active Publication Date: 2021-07-02

TONGJI UNIV

View PDF9 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Ordinary powdered electrode materials usually need to be mixed and dissolved with binders and conductive materials, and film-formed by coating and other processes. The added binders and solubilizers will seriously affect the performance of the material itself; and the coating process is complex, The requirements for the operation level of personnel are high, and the promotion of its large-scale application is not utilized. Therefore, it is very important to develop self-supporting electrode materials with excellent performance that can be directly applied

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] The invention provides a Ti 3 C 2 T x -TiO 2 Nanotube array self-supporting thin film electrode material and its preparation method and application.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

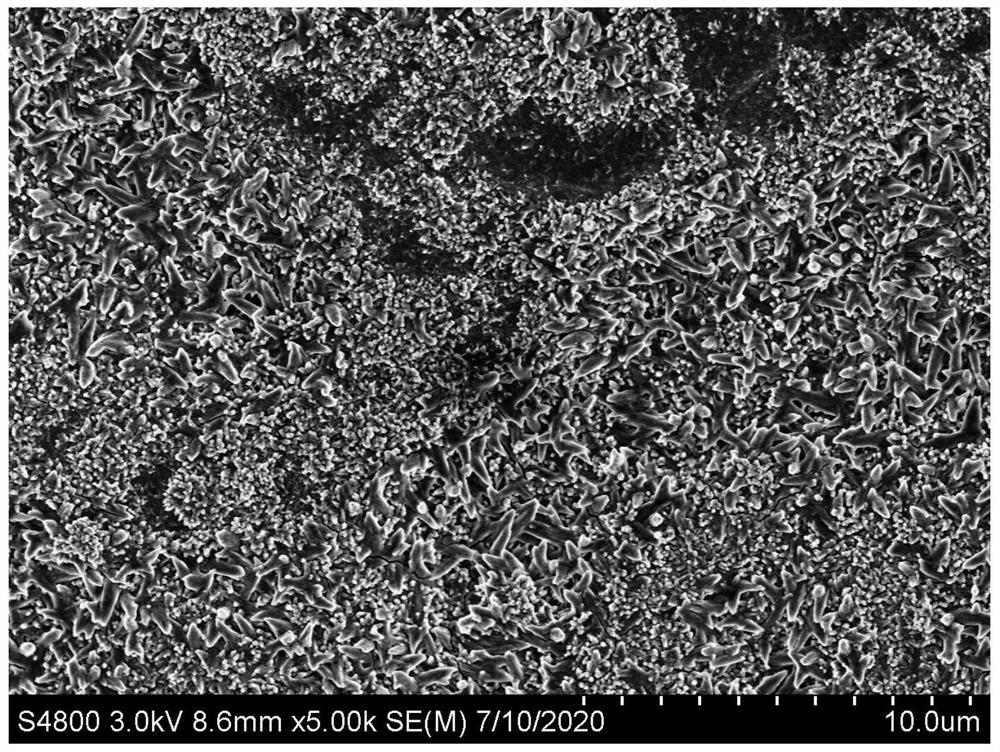

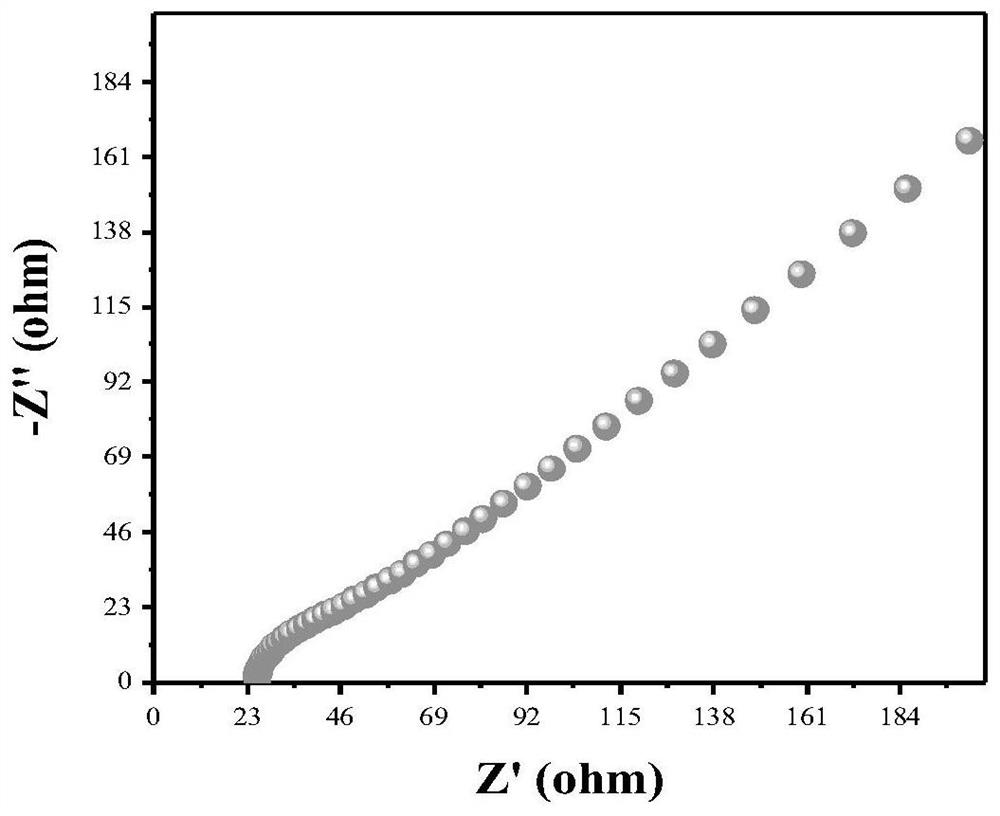

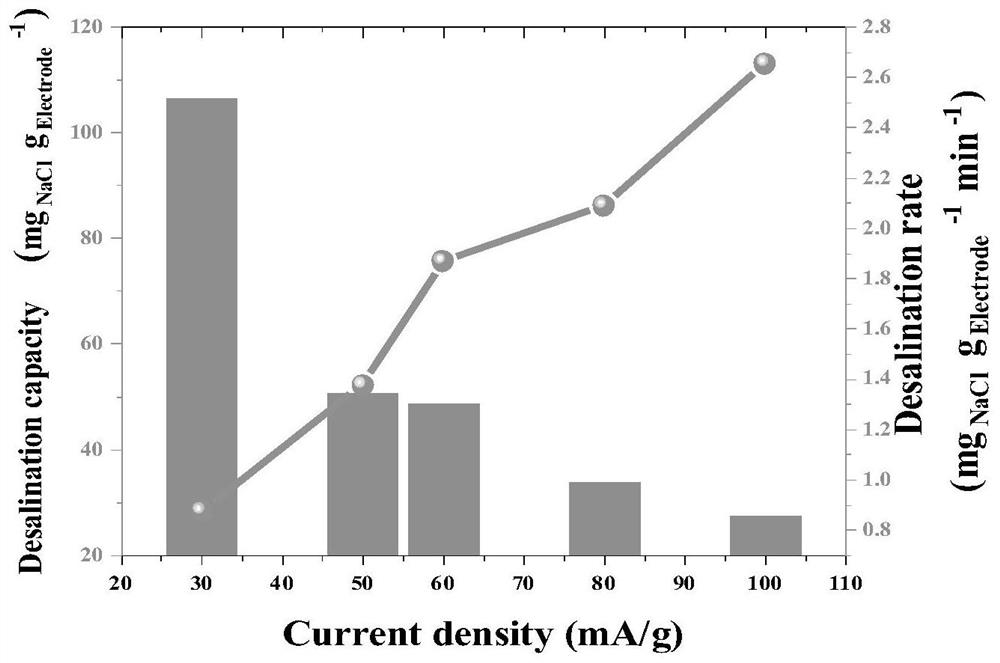

The invention provides a Ti3C2Tx-TiO2 nanotube array self-supporting film electrode material as well as a preparation method and application thereof, and belongs to the field of nano materials. The preparation method comprises the following steps: carrying out etching, cleaning, stripping and centrifuging on Ti3AlC2 to obtain a few-layer Ti3C2Tx aqueous dispersion; carrying out vacuum suction filtration on the Ti3C2Tx aqueous dispersion, and drying to obtain a Ti3C2Tx self-supporting film; and allowing the Ti3C2Tx self-supporting thin film to react in hot alkali liquor and rotate at a certain rotating speed, and cleaning and drying to obtain the Ti3C2Tx-TiO2 nanotube array self-supporting thin film. According to the prepared Ti3C2Tx-TiO2 nanotube array self-supporting thin film electrode structure, few crystal defects of the Ti3C2Tx-TiO2 nanotube structure and the array structure are beneficial to electron transmission, a large number of active sites exposed out of the nanotube array are beneficial to adsorption of ions or target pollutants, the mechanical performance is high, and the material can be directly used as an electrode material in the fields of supercapacitors, capacitive deionization, batteries, electro-adsorption and the like.

Description

technical field [0001] The invention belongs to the technical field of environmental material synthesis, in particular to a Ti 3 C 2 T x -TiO 2 Nanotube array self-supporting thin film electrode material and its preparation method and application. Background technique [0002] Electrode materials are key factors determining the performance of batteries, capacitors, and electrosorption. Ordinary powdered electrode materials usually need to be mixed and dissolved with binders and conductive materials, and film-formed by coating and other processes. The added binders and solubilizers will seriously affect the performance of the material itself; and the coating process is complex, The operation level of personnel is high, and the promotion of its large-scale application is not utilized. Therefore, it is very important to develop self-supporting electrode materials with excellent performance that can be directly applied. Contents of the invention [0003] For the deficienc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01G11/86H01G11/46H01G11/30H01G11/26H01G11/24C02F1/469H01M4/36H01M4/48H01M4/583B82Y30/00B82Y40/00

CPCH01G11/86H01G11/26H01G11/24H01G11/46H01G11/30C02F1/4691C02F1/469H01M4/364H01M4/48H01M4/583B82Y30/00B82Y40/00Y02E60/10Y02E60/13

Inventor 马杰孙怡然

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com