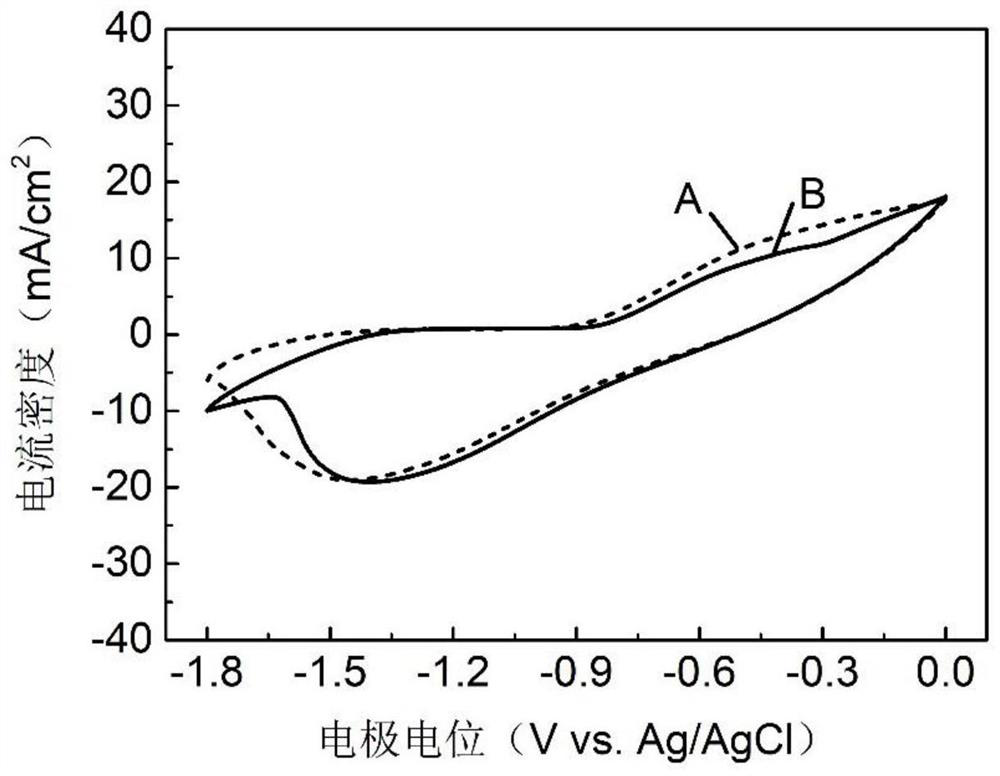

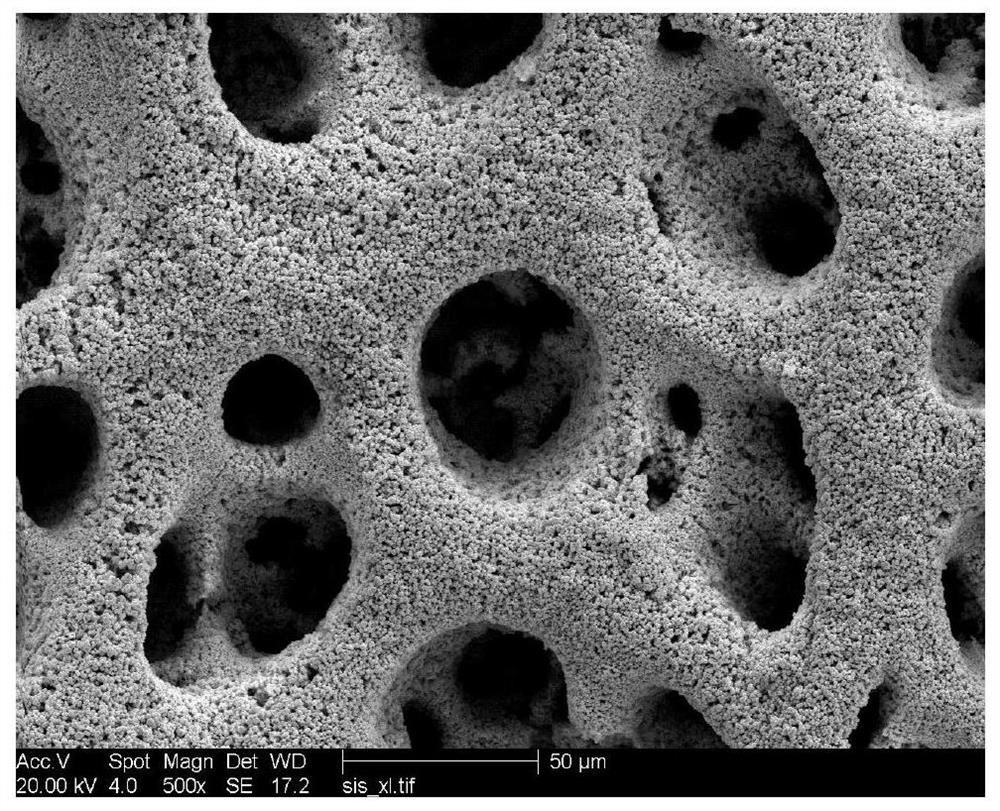

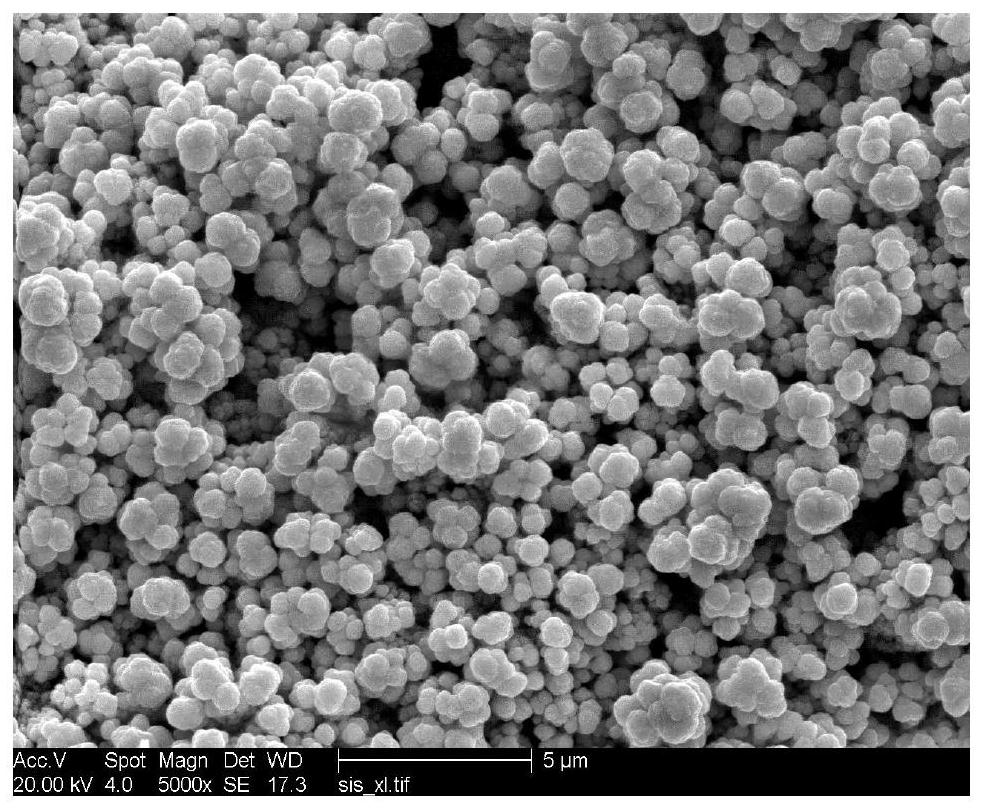

Preparation method of three-dimensional self-supporting porous CuSn alloy catalyst for producing formic acid through carbon dioxide reduction

An alloy catalyst, carbon dioxide technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of large overpotential, poor product selectivity, etc. Small electrode overpotential, high selectivity, effect of increasing catalytic kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0042] Embodiment 1: This embodiment is a method for preparing a three-dimensional self-supporting porous CuSn alloy catalyst for formic acid reduction by carbon dioxide reduction, which is carried out according to the following steps:

[0043] One, prepare the solution that copper sulfate and stannous sulfate coexist:

[0044] CuSO 4 and SnSO 4 Add to dilute H 2 SO 4 Stir and dissolve in the solution to obtain a solution in which copper sulfate and stannous sulfate coexist;

[0045] CuSO in the solution that described copper sulfate and stannous sulfate coexist 4 The concentration is 0.05mol / L~0.5mol / L;

[0046] In the solution that described copper sulfate and stannous sulfate coexist, SnSO 4 The concentration is 0.05mol / L~0.5mol / L;

[0047] 2. Electrodeposition:

[0048] Place the coexistence solution of copper sulfate and stannous sulfate in the electrolytic cell, use the Pt sheet as the counter electrode, and use the Cu sheet as the working electrode, at a current...

specific Embodiment approach 2

[0056] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the dilute H described in step one 2 SO 4 The concentration of the solution is 0.5mol / L-5mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0057] Specific embodiment three: the difference between this embodiment and one of the specific embodiments one or two is: the drying in the vacuum drying oven described in step three is specifically under the vacuum drying oven with a temperature of 20°C to 50°C, Dry 6h ~ 20h. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com