Cycling separation method for manganous dithionate in desulfurized liquid

A technology of manganese dithionate and separation method, which is applied in the field of purification and separation, can solve problems such as product quality impact, and achieve the effect of reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

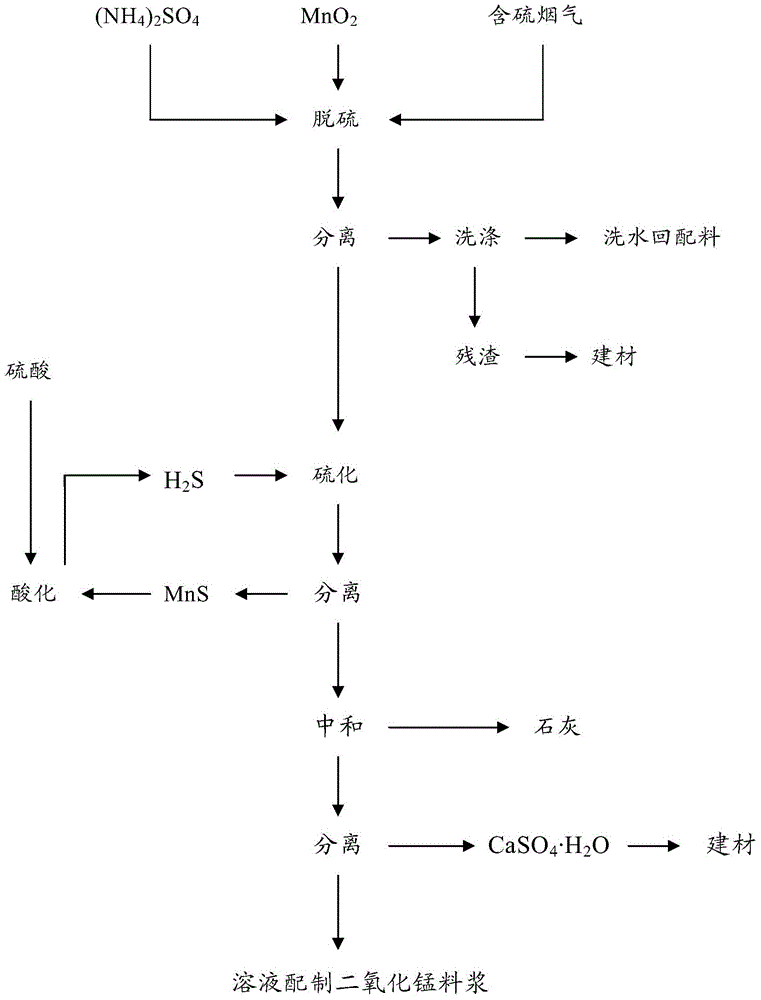

Image

Examples

Embodiment 1

[0056] (1) Desulfurization

[0057] Commercially available manganese dioxide ore powder with a particle size of 90% less than 147 μm (through a 100 mesh sieve) and a manganese content of 20% by weight is formulated into a material with a solid content of 25% by weight with ammonium sulfate solution. Slurry, the slurry is subjected to three-stage countercurrent gas-liquid reaction with sulfur-containing flue gas, and the gas velocity of sulfur-containing flue gas is controlled to be ≤1.5m / sec, and the gas-liquid ratio is 8L / m 3 , for gas-liquid reaction, to the MnO in the slurry 2 The weight percent content is less than 2%; after the reaction is finished, the slurry is neutralized to pH 6.0 with a small amount of lime, separated by pressure filtration, and the obtained filtrate enters the next step of operation. Wash the residue obtained by pressure filtration and separation, and the washing water is used to prepare manganese dioxide slurry. During the desulfurization process...

Embodiment 2

[0065] (1) Desulfurization

[0066] Commercially available manganese dioxide ore powder with a particle size of 90% less than 147 μm (through a 100 mesh sieve) and a manganese content of 45% by weight is formulated into a material with a solid content of 30% by weight with ammonium sulfate solution. Slurry, the slurry is subjected to three-stage countercurrent gas-liquid reaction with sulfur-containing flue gas, and the gas velocity of sulfur-containing flue gas is controlled to be ≤1.5m / sec, and the gas-liquid ratio is 12L / m 3 , for gas-liquid reaction, to the MnO in the slurry 2 The weight percent content is less than 1.5%; after the reaction is finished, the slurry is neutralized to pH 6.5 with a small amount of lime, separated by pressure filtration, and the obtained filtrate enters the next step of operation. Wash the residue obtained by pressure filtration and separation, and the washing water is used to prepare manganese dioxide slurry. During the desulfurization proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com