Preparation method and application of graded-structure BiOI/Bi2MoO6 composite visible light catalyst

A hierarchical structure, visible light technology, applied in the field of environmental pollution control, can solve the problem of low electron/hole separation efficiency, achieve excellent visible light catalytic degradation activity, easy preparation process, and improved degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

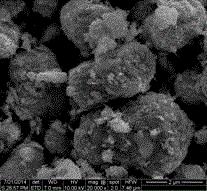

[0020] Example 1 Bi 2 MoO 6 Preparation of microspheres

[0021] Synthesis of Bi by solvothermal method 2 MoO 6 Microspheres, weighing 0.485 g Bi(NO 3 ) 3 ·5H 2 O was added to 10 mL of ethylene glycol solution, ultrasonically dispersed, and completely dissolved into a transparent solution; 60 mL of absolute ethanol was slowly added to the transparent solution, magnetically stirred, and 0.0618 g (NH 4 ) 6 Mo 7 o 24 4H 2 O, magnetic stirring to dissolve completely; move it to a 100 mL autoclave, and react at 140 °C for 16 h; after the autoclave gradually cools down to room temperature, centrifuge to precipitate, and wash with ethanol and deionized water for 3 The second time, the product was placed in an oven at 60 °C for 6 h.

Embodiment 2

[0022] Example 2 Bi 2 MoO 6 Preparation of microspheres

[0023] Synthesis of Bi by solvothermal method 2 MoO 6 Microspheres, weighing 0.97 g Bi(NO 3 ) 3 ·5H 2 O was added to 20 mL of ethylene glycol solution, ultrasonically dispersed to make it completely dissolved into a transparent solution; 50 mL of absolute ethanol was slowly added to the transparent solution, magnetically stirred, and 0.1236 g (NH 4 ) 6 Mo 7 o 24 4H 2 O, magnetic stirring to make it completely dissolved; move it to a 100 mL autoclave, and react at 160 °C for 12 h; after the autoclave gradually cooled to room temperature, centrifuge to precipitate, wash with ethanol and deionized water for 3 The second time, the product was placed in an oven at 70 °C for 5 h.

Embodiment 3

[0024] Example 3 Bi 2 MoO 6 Preparation of microspheres

[0025] Synthesis of Bi by solvothermal method 2 MoO 6Microspheres, weighing 1.455 g Bi(NO 3 ) 3 ·5H 2 O was added to 30 mL of ethylene glycol solution, ultrasonically dispersed, and completely dissolved into a transparent solution; 40 mL of absolute ethanol was slowly added to the transparent solution, magnetically stirred, and 0.1854 g (NH 4 ) 6 Mo 7 o 24 4H 2 O, magnetic stirring to dissolve completely; move it to a 100 mL autoclave, and react at 180 °C for 10 h; after the autoclave gradually cools down to room temperature, centrifuge to precipitate, and wash with ethanol and deionized water for 3 The second time, the product was placed in an oven at 80 °C for 4 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com