Cutter, Device And Method For Manufacturing Cutter

A technology for manufacturing devices and knives, which is applied in the field of improving the structure of knives, and can solve the problems of increased cutting resistance, easy damage, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

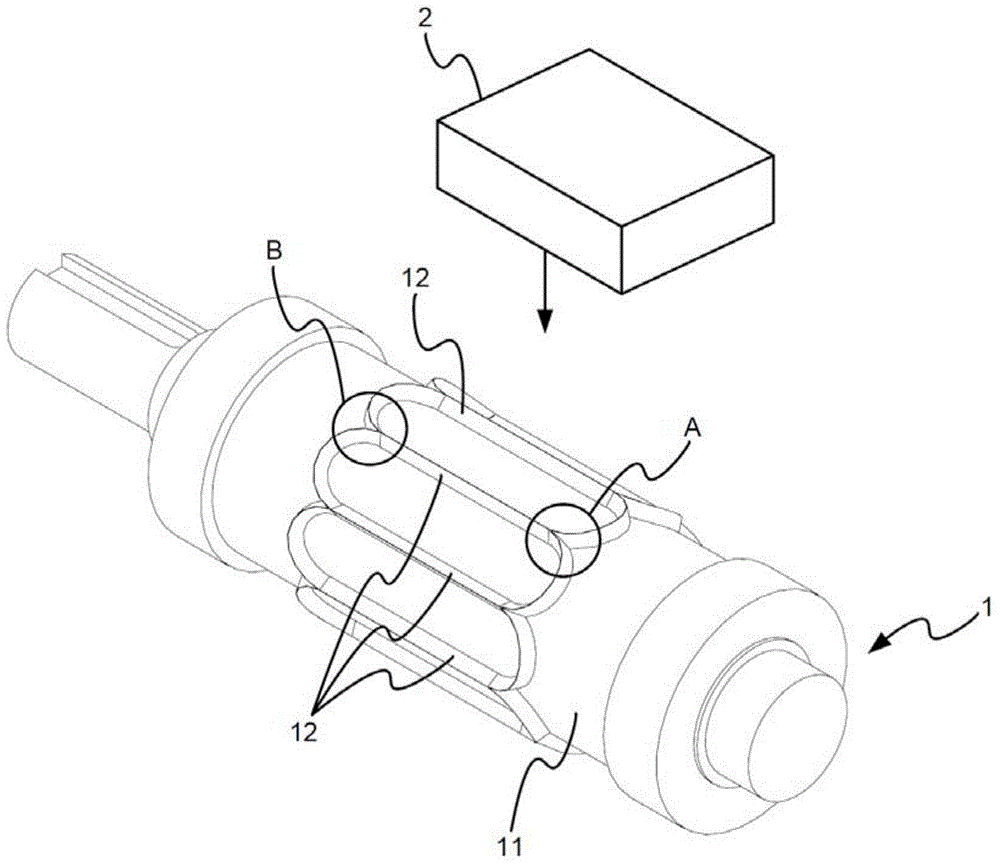

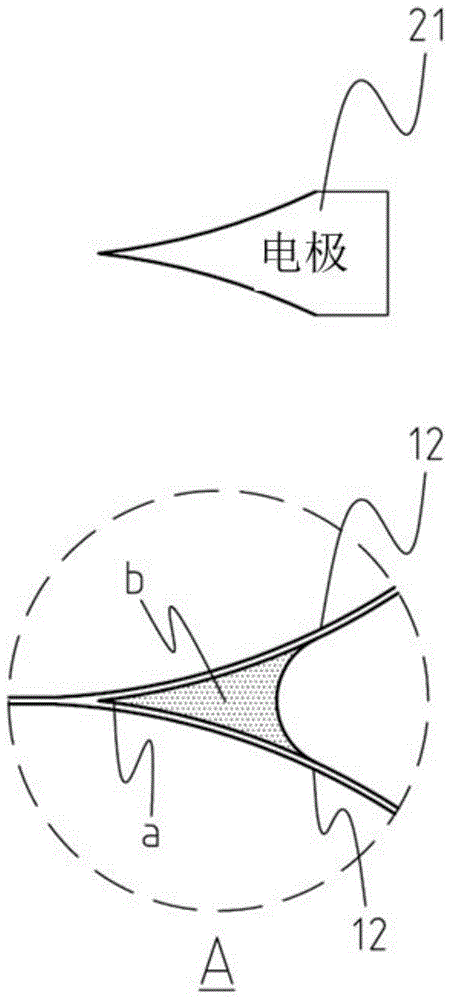

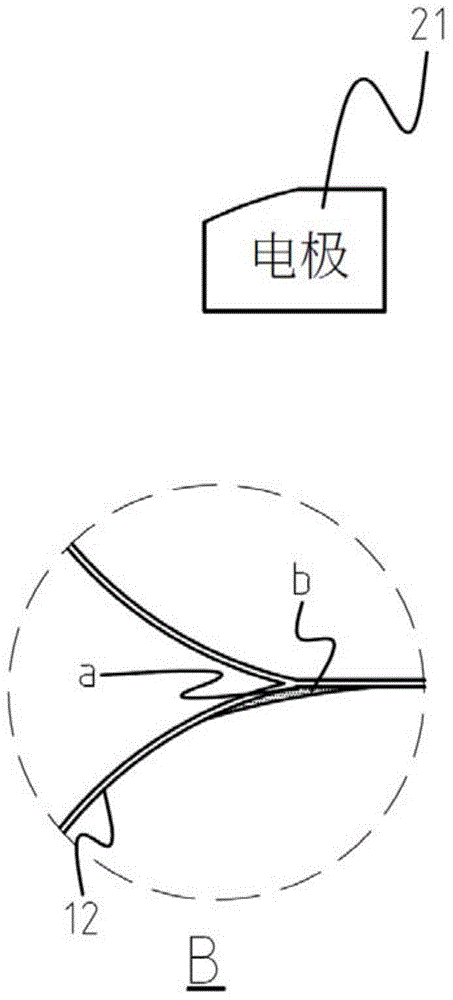

[0024] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 as shown, figure 1 It is a schematic diagram of the present invention. The present invention is a cutter for manufacturing medical dressings and patches and its manufacturing device and method. The cutter 1 includes a cutter wheel body 11, and a plurality of cutting blades 12 formed by processing the cutter wheel body 11. In the illustration of this embodiment, there are a plurality of adjacent cutting blades 12, but the present invention does not limit the plurality of cutting blades 12 to be adjacent to each other or not, and no matter whether it is one cutting blade, multiple phases Adjacent or non-adjacent cutting blades are suitable for the manufacturing apparatus and method of the present invention. The cutting tool manufacturing device includes an electrical discharge machining mechanism 2 corresponding to the cutting tool 1 . figure 2 for the invention figure 1 The enlarged schematic diagram o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com