Full-automatic cement foaming machine and process control

A technology for cement foaming and process control, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as damage to building structures, increased building loads, and low production technology levels, and achieve stable bulk density. , The effect of improving the level of production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

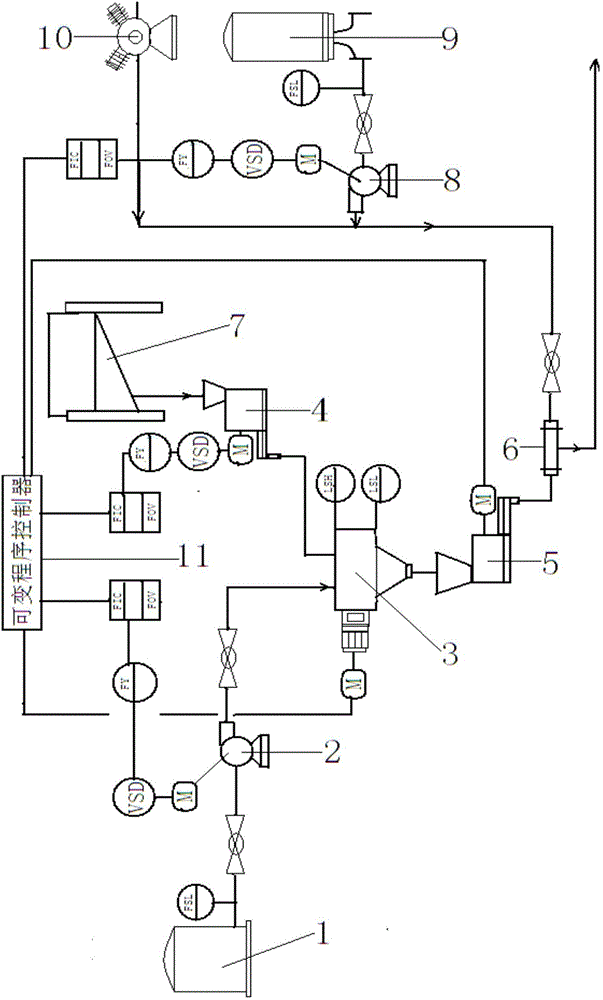

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Full-automatic cement foaming machine provided by the present invention and process control, its concrete operation is:

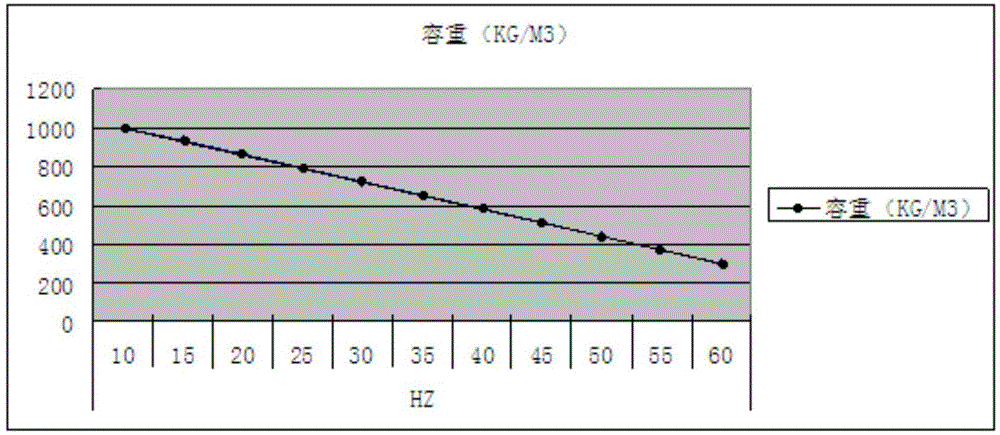

[0022] In the first step, the correlation curve between water, ash, foam injection volume and bulk density is obtained through qualitative experiments on foam concrete with different bulk density. The parameters of the specific curve are shown in the attached figure 2 shown.

[0023] In the second step, the data of the correlation curve is input into the variable program controller 11;

[0024] In the third step, input the required water-cement ratio and foam bulk density on the touch screen of the variable program controller 11, and the variable program controller 11 automatically calculates the frequency required by the variable frequency motor, and then passes the variable program The controller 11 supplies the calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com