Molded capping machine

The technology of capping machine and pressing die is applied in the field of molding capping machine, which can solve the problems of difficult oil circuit processing, poor quality, low production efficiency of bottle caps, etc., so as to improve the molding quality, reduce the number of parts, and improve the cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

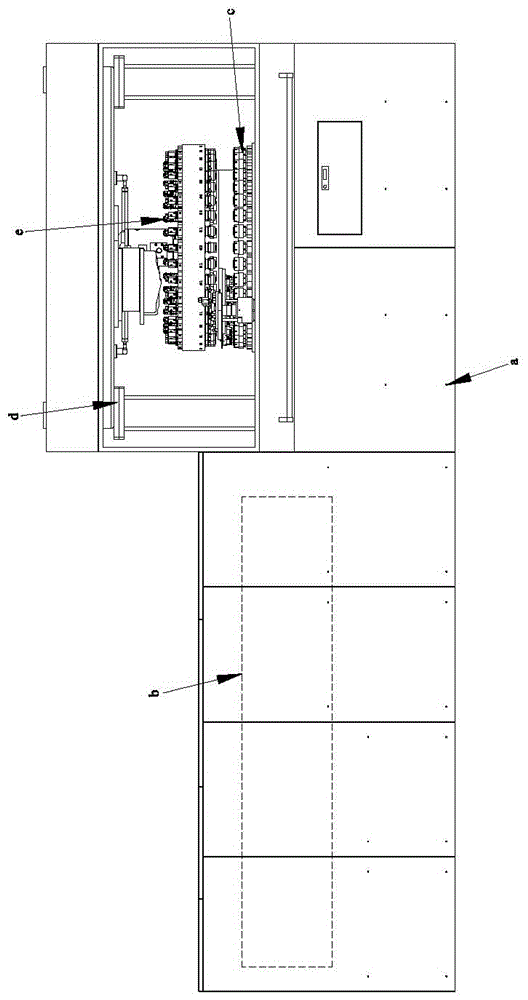

[0091] Please refer to Figure 1 to Figure 17 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a frame a and an extrusion die set b, a pressing die set c, and an input and output die set d arranged on the frame a.

[0092] The specific structure of the extrusion die set b is an existing mature technology, and the specific structure of the extrusion die set b will not be described in detail here.

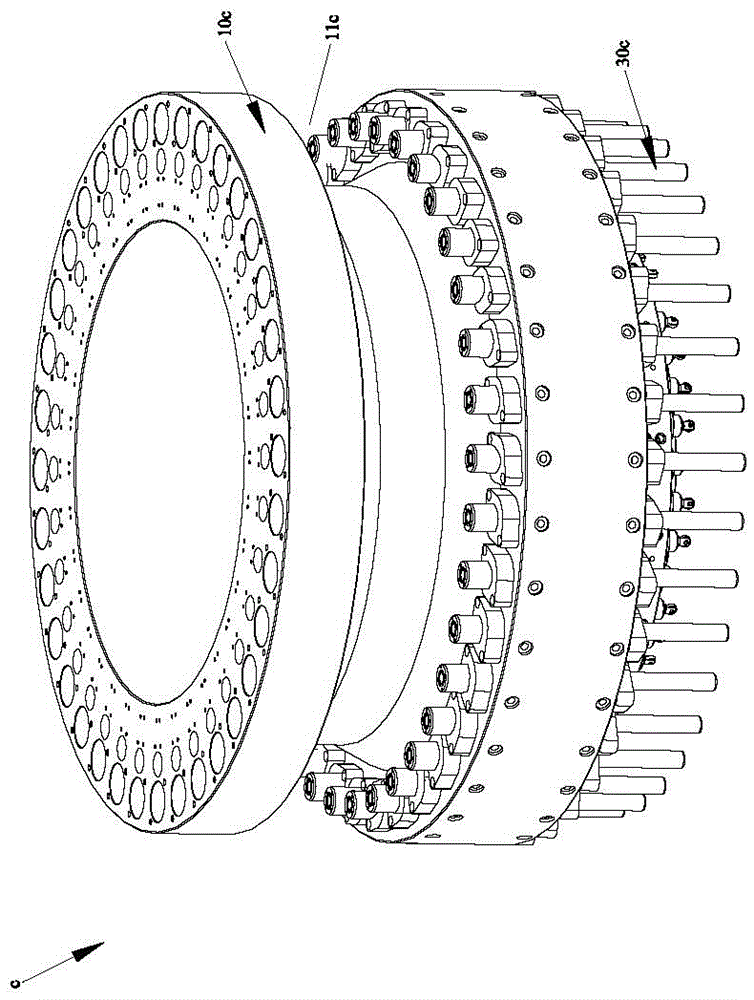

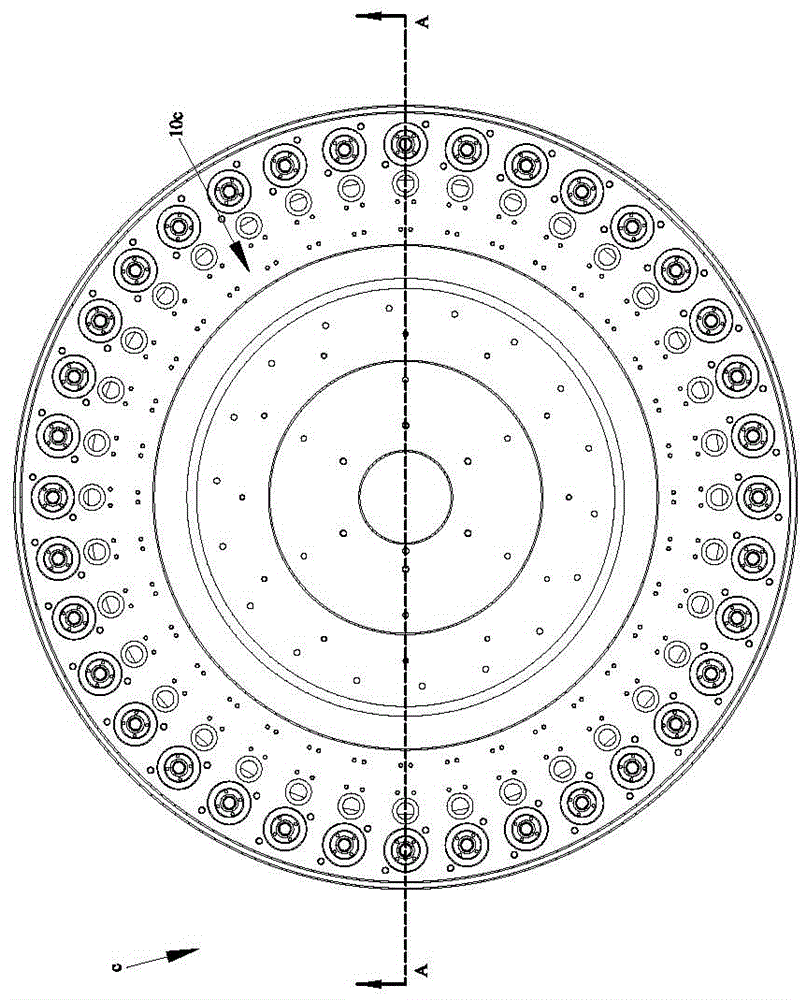

[0093] Such as Figure 2 to Figure 8 As shown, the pressing module c includes a rotating body 10c and an oil circuit splicing body 20c.

[0094] Wherein, the rotating body 10c is an annular body, and the outer peripheral side of the rotating body 10c forms an annular space 11c, and a plurality of piston cavities 12c are evenly distributed on the periphery of the rotating body 10c, and each piston chamber 12c is provided with a piston rod 30c , the top end of the piston rod 30c extends into the annular space 11 and is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com