Turbine-type aeration machine

An aerator and turbine-type technology, applied in the field of aerator, can solve the problems of complex structure and low work efficiency, and achieve the effects of simplifying structure, improving work efficiency, improving oxygen transfer efficiency and oxygenation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

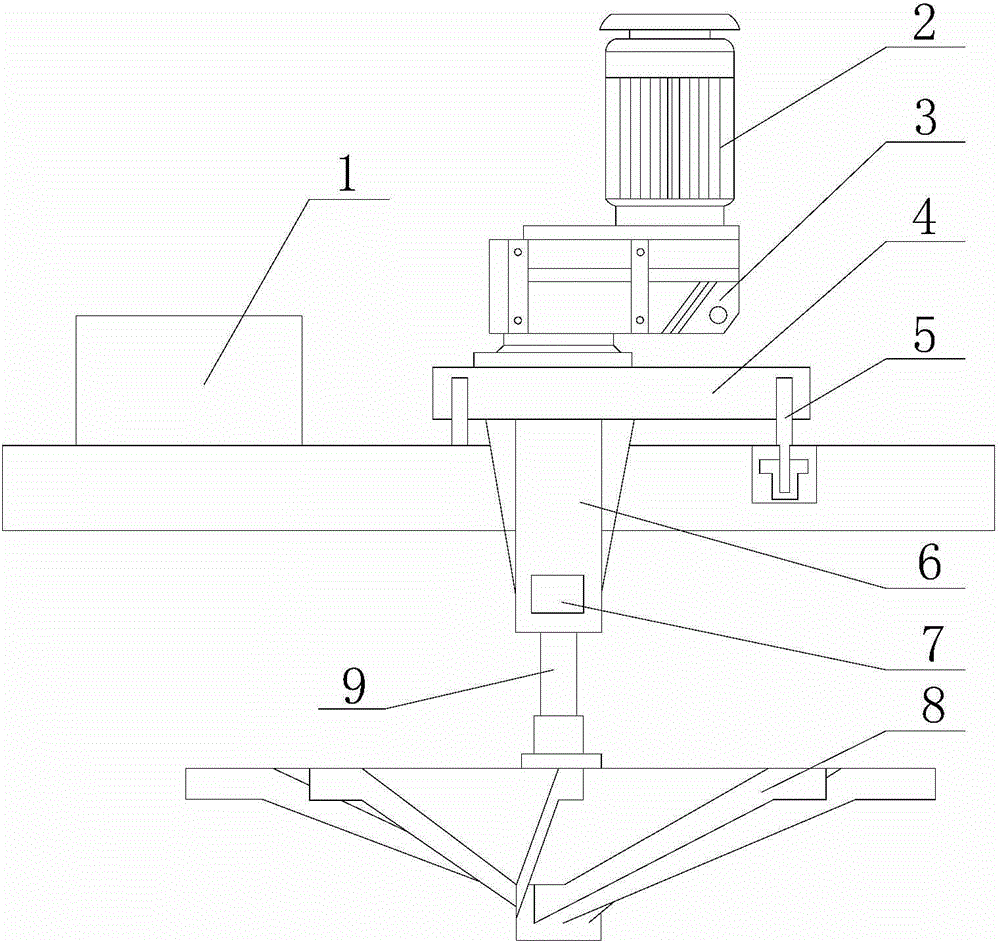

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 As shown, a turbine aerator of the present invention includes a controller (1), a motor (2), a frame (4), a height adjustment device (5), a main shaft (9) and an impeller (8), and the controller The control signal output terminal of (1) is connected to the control signal input terminal of the motor (2), the frame (4) is connected to the ground on the pool through the height adjustment device (5), and the lower part of the motor (2) is provided with a reduction box ( 3), the rotating shaft of the motor (2) is connected to the main shaft (9) through the reduction box (3), the lower end of the main shaft (9) is connected to the impeller (8), and the impeller (8) is located under the water surface in the pool.

[0014] A turbine aerator also includes an inverted umbrella seat (6), the main shaft (9) is arranged in the inverted umbrella seat (6), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com