Method for preparation of drifting road subgrade filler from oil field oily sludge

A technology of roadbed filler and oil sludge, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of complex components, safety and health hazards, etc., to improve treatment capacity, reduce treatment costs, improve The effect of resource utilization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

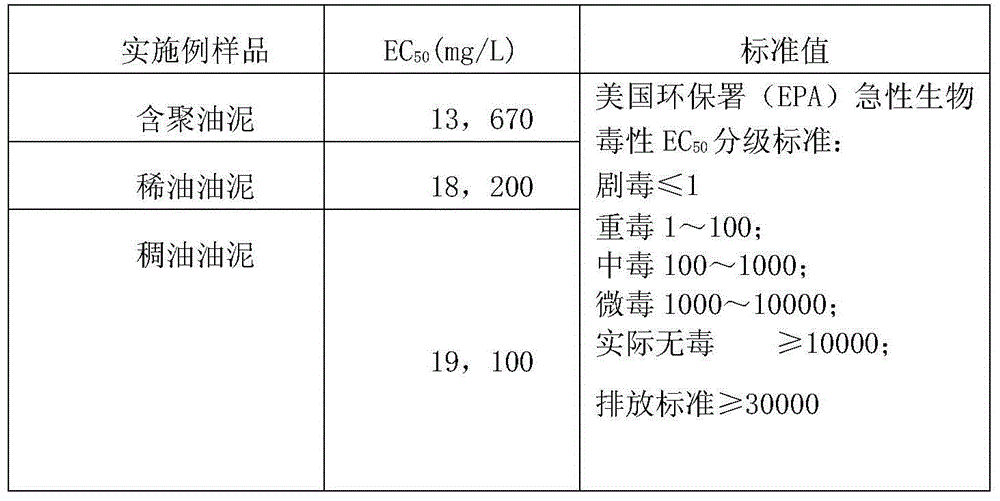

[0030] Example 1: Typical Oilfield Oily Sludge - Polymer Sludge

[0031] (1) Take an appropriate amount of oil sludge containing polymers in an oil field, and remove weeds, tree roots, plastics and other components;

[0032] (2) Wash the oily sludge with tap water at 60°C or use chemicals at room temperature to recover the dirty oil;

[0033] (3) Solid-liquid separation of oily sludge is carried out by centrifugation, the moisture content of the remaining solids is 53%, and the petroleum hydrocarbons are reduced to ≤2%;

[0034] (4) Weigh 500g of residual sludge after treatment, add 50g of curing agent, 45g of drying agent, 20g of fine aggregate and 1.5g of improvement additive, and stir well;

[0035] (5) at Vibrate evenly in a stainless steel mold, cover with film, and carry out standard curing in the curing box;

[0036] (6) The sample was tested after 7 days, and its CBR value was 9.34%, the unconfined compressive strength was 2.69, and the plasticity index was 18.3%. ...

Embodiment 2

[0039] Example 2: Typical oilfield oily sludge—thin oily sludge

[0040] (1) Take an appropriate amount of thin oil sludge from an oilfield to remove weeds, tree roots, plastics and other components;

[0041] (2) Heat and wash the oily sludge with tap water at 60°C or use chemical agents at room temperature to recover the dirty oil;

[0042] (3) Solid-liquid separation of oily sludge is carried out by centrifugation, the moisture content of the remaining solids is 65.4%, and the petroleum hydrocarbons are reduced to ≤2%;

[0043] (4) Weigh 500g of residual sludge after treatment, add 46g of curing agent, 56g of drying agent, 20g of fine aggregate and 1g of improvement additive, and stir well;

[0044] (5) at Stir and oscillate evenly in a stainless steel mold, cover it with a film, and perform standard maintenance in a curing box;

[0045] (6) The test sample was obtained after 7 days, with a CBR value of 7.26%, an unconfined compressive strength of 2.13, and a plasticity ...

Embodiment 3

[0048] Example 3: Typical Oilfield Oily Sludge - Heavy Oil Sludge

[0049] (1) Take an appropriate amount of heavy oil sludge from Liaohe Oilfield, and remove weeds, tree roots, plastics and other components;

[0050] (2) Use the anaerobic pyrolysis device to pyrolyze the oily sludge at 600°C to recover waste oil and non-condensable gas;

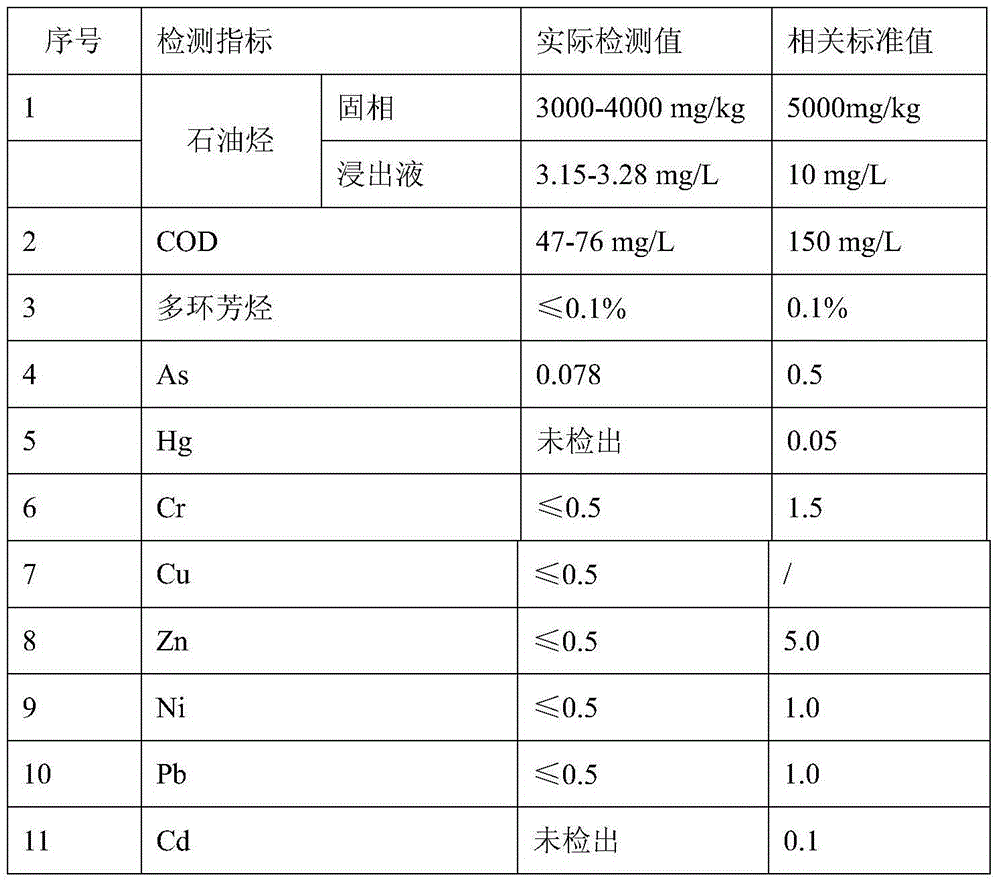

[0051] (3) The moisture content of the remaining solids is less than 0.1%, petroleum hydrocarbons are reduced to ≤0.3%, its CBR value is 8.04%, the unconfined compressive strength is 2.01, and the plasticity index is 10.45%, which meets the requirements of fillers;

[0052] (4) Put the above sample at 0.5t / m 3 The proportion is mixed with the local road construction soil. After treatment, the CBR value is 43.8%, the plasticity index is 10.51, and the degree of compaction is 93%. The maximum dry density is 2.00g / m 3 . The main pollutants in the subgrade samples can meet the requirements of "Soil Environmental Quality Standard 2008" (draft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com