An emulsified viscosity-reducing oil displacement composition suitable for heavy oil reservoirs

A technology for emulsifying viscosity-reducing heavy oil reservoirs, applied in the field of chemical compound flooding, which can solve the problems of crude oil loss in reservoirs, such as crude oil viscosity, oil washing, unobvious oil displacement effect, high water content of single well in oil layer, etc., and achieve good emulsification performance , The effect of washing oil is good, and it is easy to buy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

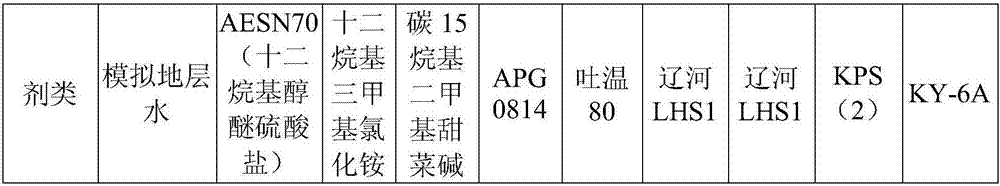

[0027] Different types of industrial active agents and simulated formation water were used to treat crude oil in a certain block of Liaohe River (crude oil density = d = 0.9137g / cm 3 ) to prepare oil sand (80-100 mesh) washing effect. Oil washing process: Weigh a certain amount of oil sand and put it into the oil washing bottle, inject various prepared agents (prepared with corresponding simulated formation water) respectively, and then put it into an air bath shaker to keep warm and shake for 2 hours (oscillation speed = 150-160r / min), then take it out and put it in a thermostat for 5 hours (55°C) to keep warm for 5 hours, record the results, and calculate the oil washing efficiency (oil washing efficiency = mass of precipitated oil / mass of oil contained in original oil sand × 100%), The experimental results are shown in Table 2.

[0028] Table 2

[0029]

[0030]

[0031] From the experimental results, it can be seen that the simulated formation water in the Liaohe oil...

Embodiment 2

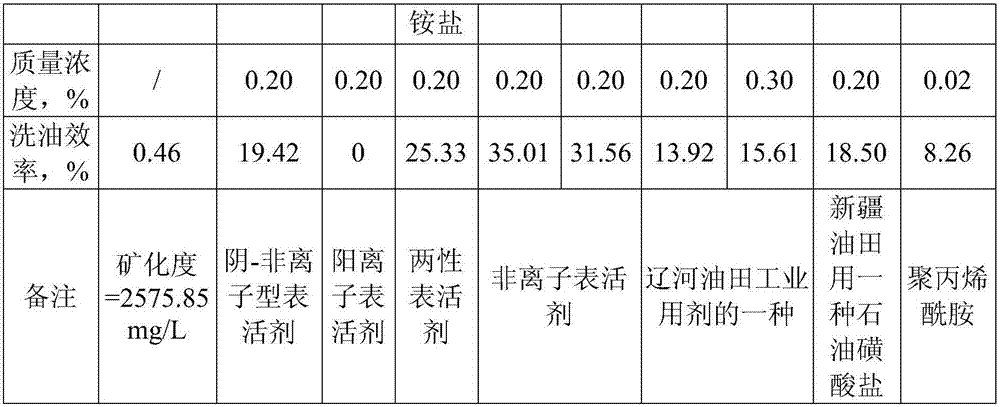

[0033] Using 80-100 mesh to simulate oil sand in a certain block of Liaohe River, aged at 80°C for 20 days, the viscosity of the crude oil used in the emulsification experiment was 4652mPa·s at 80°C. The prepared various compounding agents (PAAS and another additive, prepared with corresponding simulated formation water) were injected respectively, shaken in the air bath shaker for 2 hours and then kept for 5 hours, and the oil washing efficiency test experiment was carried out. The results are as follows: Shown in Table 3 (concentration % of various agents in Table 3 all refers to mass concentration, and herein, unless otherwise specified, concentration % all refers to mass concentration).

[0034] table 3

[0035]

[0036] The system viscosity of the complex agent is not high, and the emulsification stability is better. The combination of PAAS and APG has the best oil removal efficiency, and the combination with T80 has higher oil removal efficiency. The emulsion formed ...

Embodiment 3

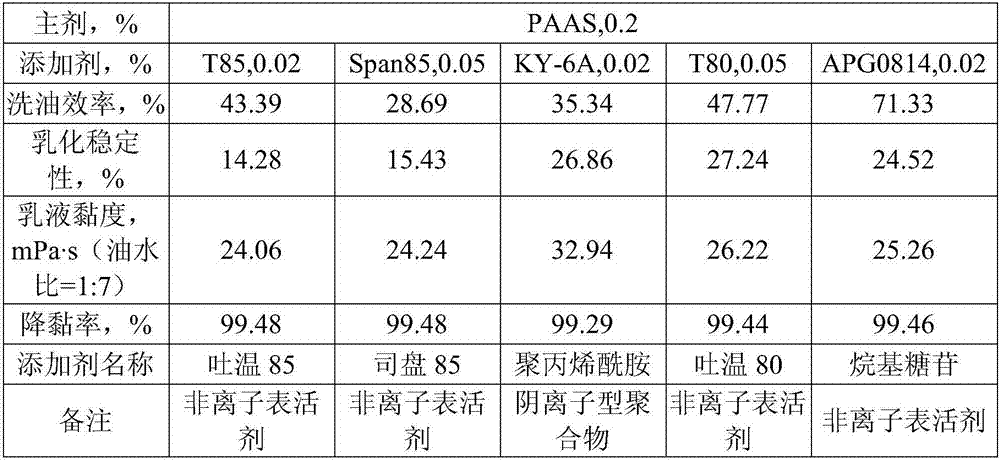

[0038] Using 80-100 mesh simulated oil sand in a certain block of Liaohe River, aging at 55°C for 20 days, injecting prepared various compounding agents (PAAS and APG0814 with different mass concentrations, prepared with corresponding simulated formation water), Shake in a bath shaker for 2 hours, then keep warm for 5 hours, and carry out the oil washing efficiency test experiment, the results are shown in Table 4.

[0039] Table 4

[0040]

[0041] The content of PAAS is 0.2%, and the content of APG0814 is from 0.02% to 0.10%. The experimental results of these four groups show that the oil washing efficiency exceeds 60%, which is a very good effect. The best of these is a combination of the two with a mass ratio of 5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com