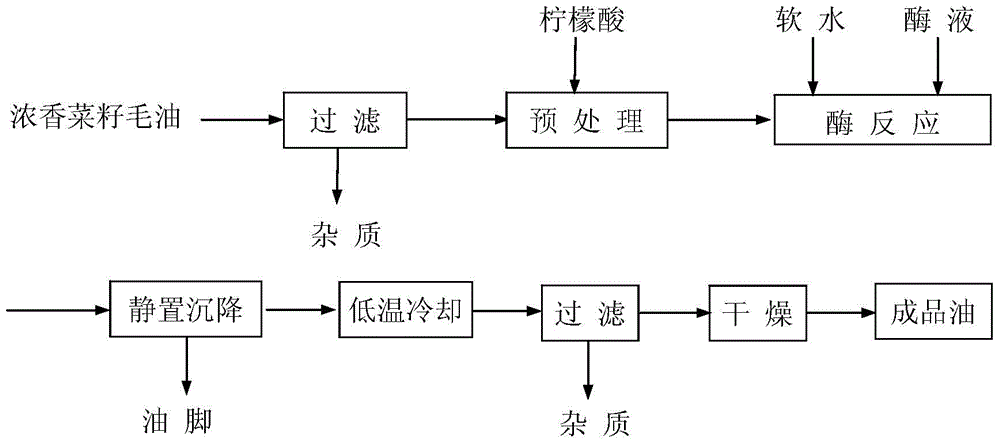

Method for degumming fragrant rap oil through enzymic process

A technology of rapeseed oil and strong aroma, which is applied in the direction of fat oil/fat refining and fat production, which can solve the problems of low refining yield, coking of equipment, and affecting the effect of degumming, and achieve low oil content on dry basis and high oil foot volume The effect of reducing and avoiding oil loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Put the crude rapeseed oil obtained by cleaning and frying the seeds and pressing the oil making process to stand for 24 hours, then centrifuge or mechanically filter out most of the impurities contained in it, and the impurity-removed crude oil passes through the heat exchanger in the enzymatic hydrolysis tank Heat to 40°C-45°C.

[0023] 2. Dissolving the citric acid solid in demineralized water to prepare a citric acid solution with a mass concentration of 50% in the acid tank for subsequent use.

[0024] 3. Add 50% citric acid solution according to the proportion of 0.4% of the oil weight, and stir and mix. The stirring and mixing speed is 50r / min, and the time is 60 minutes.

[0025] 4. Transfer the oil and acid mixture in the acid reaction tank to the enzyme reaction tank, add soft water, the temperature of the soft water is 5°C higher than the oil temperature, the amount of soft water added is about 1.8% of the oil, stir well and evenly, and then press 0.13% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com