Three-level acceleration type spiral wave plasma propulsion device

A plasma and three-stage acceleration technology, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of accelerated ions and insufficient thrust performance, and achieve high reliability, broad application prospects, and high propulsion capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

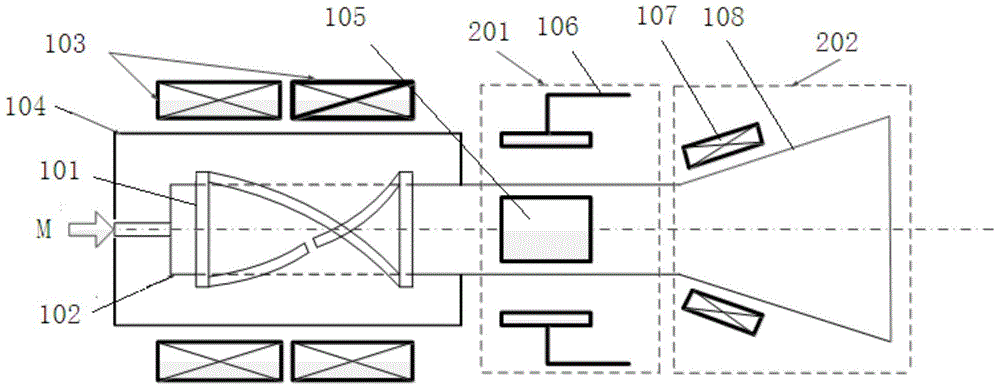

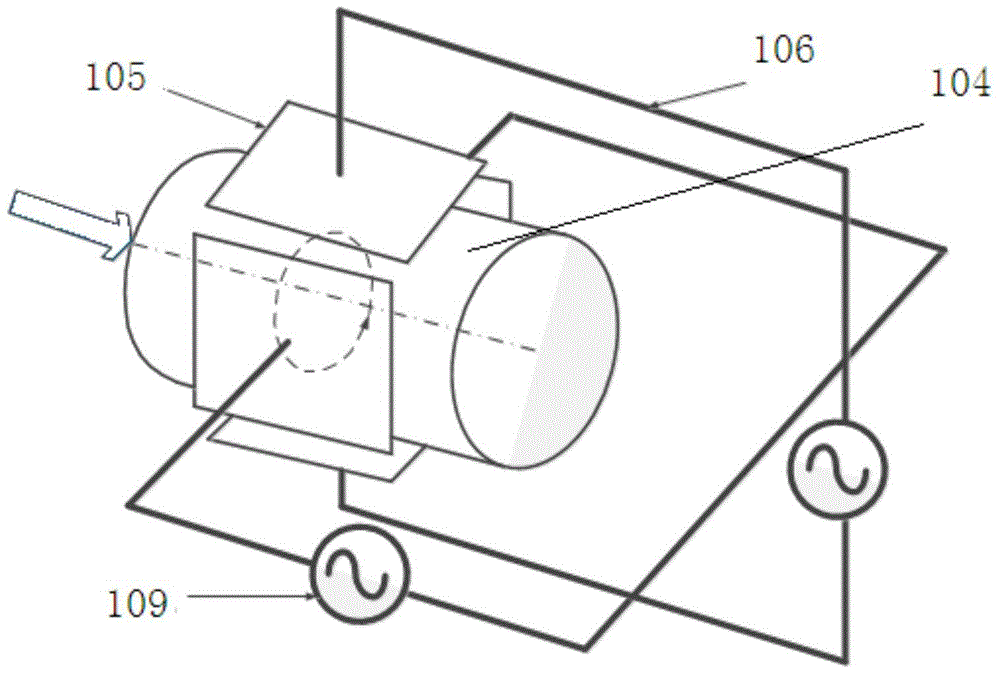

[0009] figure 1 and figure 2 It is a schematic diagram of the structure of this three-stage accelerated helicon wave plasma propulsion device. It can be seen from the figure that its shoji-type antenna 101 is connected to a radio frequency power source and fixed around the outside of the discharge chamber 102 . Both the shoji type antenna 101 and the discharge chamber 102 are fixed inside the sleeve 104 . The electromagnetic coil i-103 is regularly and orderly fixed on the outer peripheral surface of the sleeve 104 . The electromagnetic coil i-103 is surrounded by a hollow copper tube. The working gas comes out of the gas storage chamber and then enters the discharge chamber 102 through the hollow copper tube. This process can not only cool the copper tube, but also preheat the working gas. The sleeve 104 is made of carbon fiber composite material. The discharge chamber 102 is used to shield the plasma in a certain area to prevent the equipment from being corroded. The sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com