A waste heat recovery cycle device

A technology of waste heat recovery and circulation device, which is applied to household heating, heating methods, water heaters/stoves, etc., can solve the problem of ineffective utilization of low-grade waste heat, achieve simple structure, increase heat exchange efficiency, and prolong residence time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

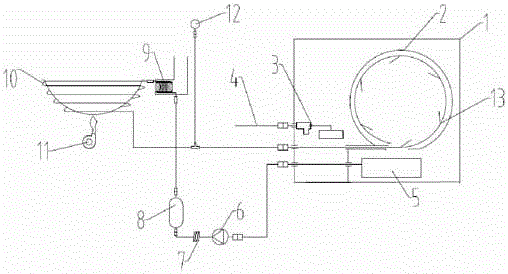

[0015] Embodiment one, such as figure 1 As shown, a waste heat recovery circulation device, the water replenishment port 4 is the water inlet, 1 is the steamer, and a float valve 3 inside it is used to replenish water at a fixed liquid level. When the float valve 3 drops, the water replenishment tank automatically replenishes water. The replenishment water enters the contact steam generator 2 through the replenishment port 4, passes through the filter 5, and the filter 5 can filter out the sundries (such as rice, steamed buns, etc.) dropped from the steamer 1, and there is a The water pump 6 and the water pump 6 work to extract the water passing through the filter 5 in the contact steam generator 2, and then the shock absorber 7 enters the descaler 8, wherein the function of the shock absorber 7 is to gently pass the water pumped out by the water pump 6 The vibration makes the water entering the descaling device a gentle flow. This descaling device 8 uses infrared ceramics to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com