High temperature and high pressure coal and rock true triaxial fracturing and seepage test device and test method

A high-temperature and high-pressure, test-device technology, used in measuring devices, using stable tension/pressure to test material strength, permeability/surface area analysis, etc., can solve problems such as inability to meet hydraulic fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

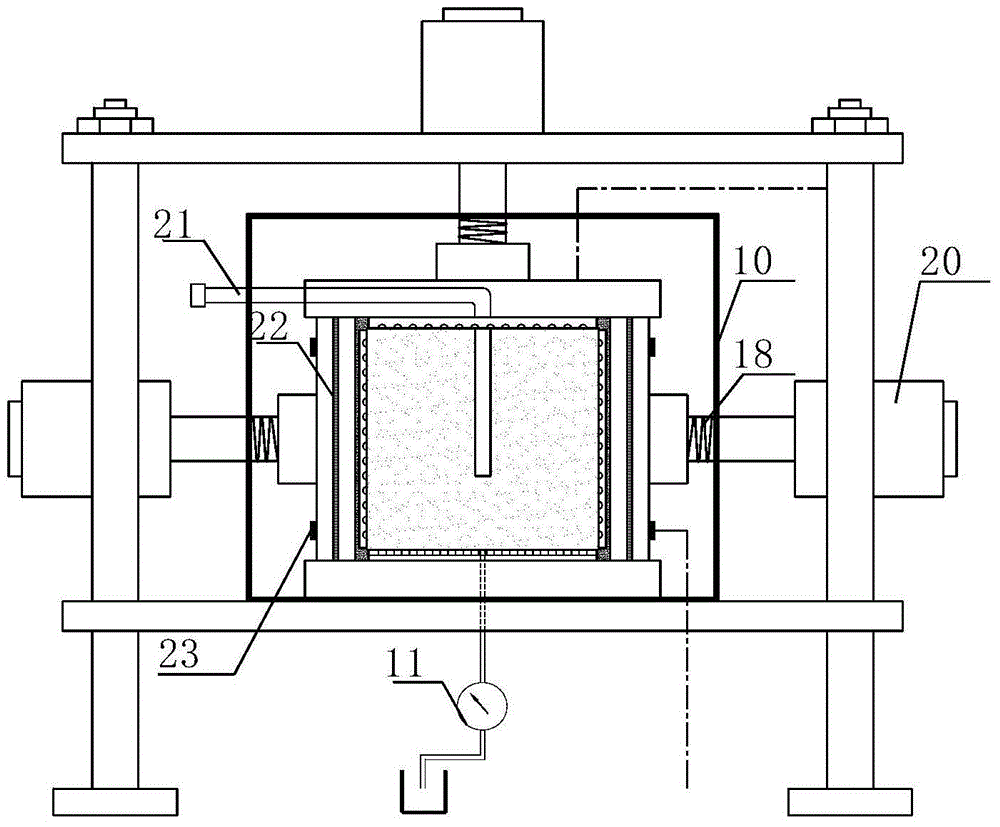

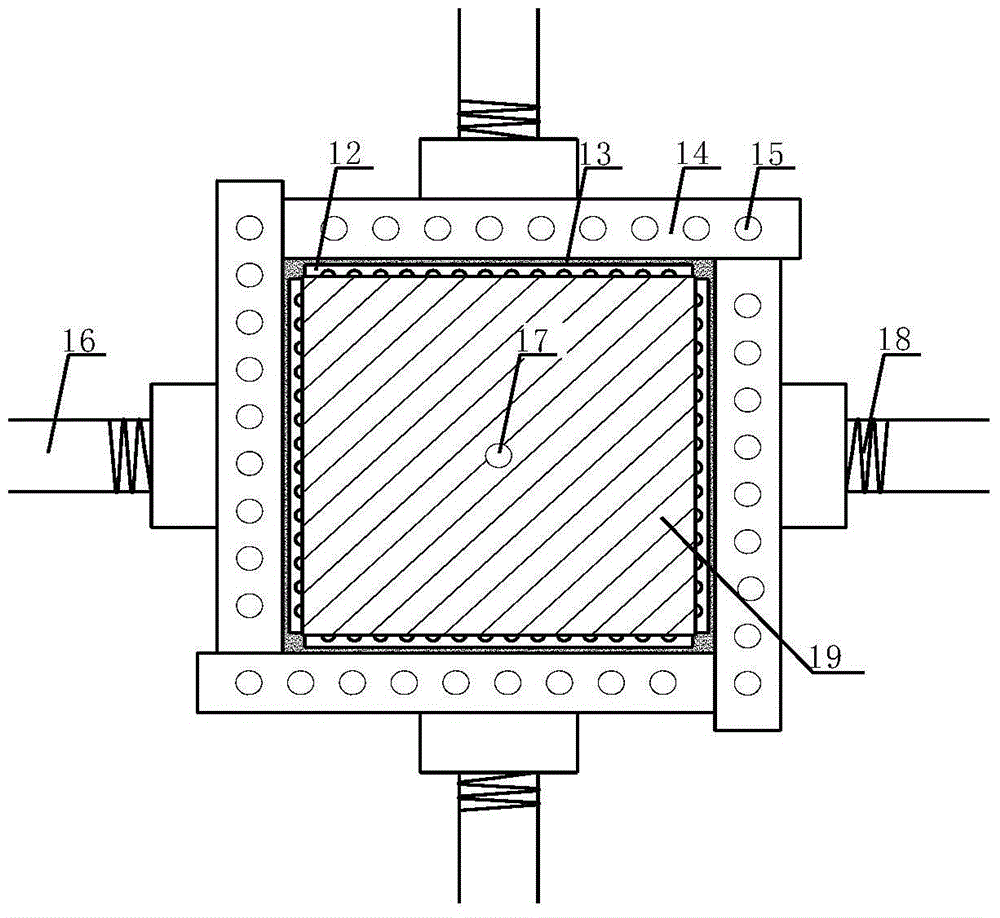

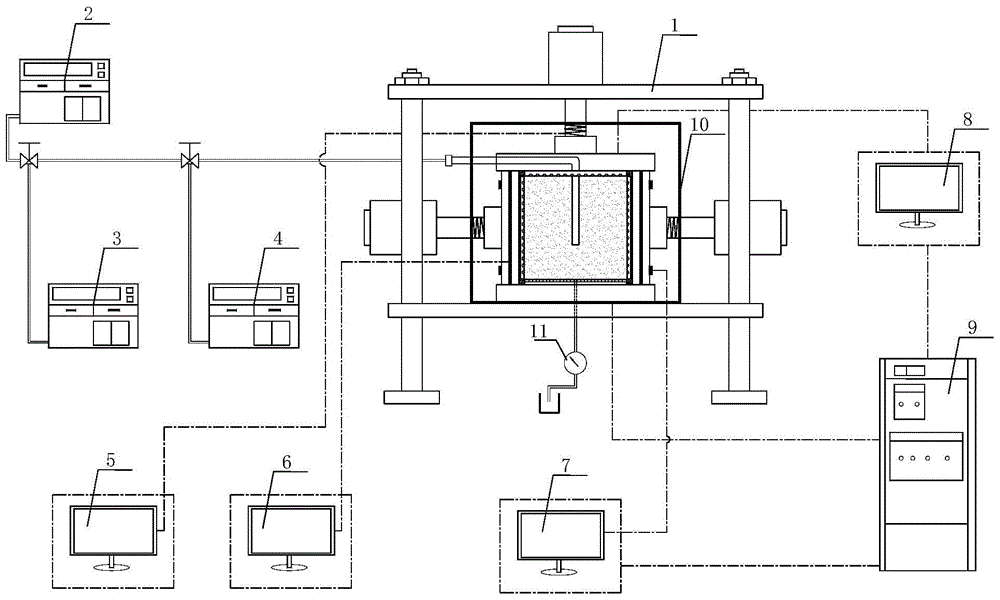

[0033] Detailed ways: According to the requirements of the experiment, there are two options for the size and specification of the coal rock specimen 19, namely: 100×100×100mm or 300×300×300mm. The test device can meet the test requirements of simulating the geological environment conditions of mineral burial depth up to 2000m, and the test piece 19 is heated to 400° C. through the heating rod 22 .

[0034] The true triaxial real-time loading system 1 loads different axial pressures and horizontal pressures in two directions on the test piece 19, so as to simulate the real burial geological environment of minerals. The fracturing fluid injection system uses a set of servo booster pumps to inject fracturing fluid or supercritical CO into the simulated wellbore 2 Fracturing was performed on specimen 19. The temperature loading and heat preservation control system 6 mainly provides a predetermined heating temperature for the test piece 19 so that the test piece 19 is evenly he...

Embodiment approach 1

[0036] In this implementation example, 100×100×100 mm is taken as an example. Hydraulic fracturing was selected as the fracturing method, the stress condition of the 2000m deep formation was simulated, and the temperature loading was selected as 400°C.

[0037] Adopt the experimental method of the test device of described simulation hydraulic fracturing process, comprise the steps:

[0038] Step 1: Before the experiment, process and drill a central hole 17 of Φ10mm and a depth of 70mm on the 100×100×100mm test piece 19. This hole is used to insert the fracturing string 21 to simulate the wellbore, and the central hole 17 inserted into the string is drilled. Sealing;

[0039] Step 2: Seal the test piece 19 and the porous plate groove 12 with the ultra-high temperature resistant sealant 13, and clamp it with the pressure transmission plate 14 and send it into the pressure chamber;

[0040] Step 3: Connect each monitoring device, perform true three-axis servo loading, and apply...

Embodiment approach 2

[0047] In this implementation example, 300×300×300mm is taken as an example. Hydraulic fracturing was selected as the fracturing method, the stress condition of the 1000m deep formation was simulated, and the temperature loading was selected as 250°C.

[0048] Adopt the experimental method of the test device of described simulation hydraulic fracturing process, comprise the steps:

[0049] Step 1: Before the experiment, process and drill a central hole 17 of Φ20 mm and a depth of 250 mm on the 300 × 300 × 300 mm test piece 19, which is used to insert the fracturing string 21 to simulate the wellbore, and seal the central hole of the inserted string hole;

[0050] Step 2: Seal the test piece 19 and the porous plate groove 12 with the ultra-high temperature resistant sealant 13, and clamp it with the pressure transmission plate 14 and send it into the pressure chamber;

[0051] Step 3: Connect each monitoring device, perform true three-axis servo loading, and apply axial press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com