Method for simulating linear polymer crystallization

A linear polymer, polymer technology, applied in special data processing applications, instruments, electrical digital data processing, etc. The alignment process cannot be revealed, and the crystal structure information cannot fully represent the crystallization behavior of the polymer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

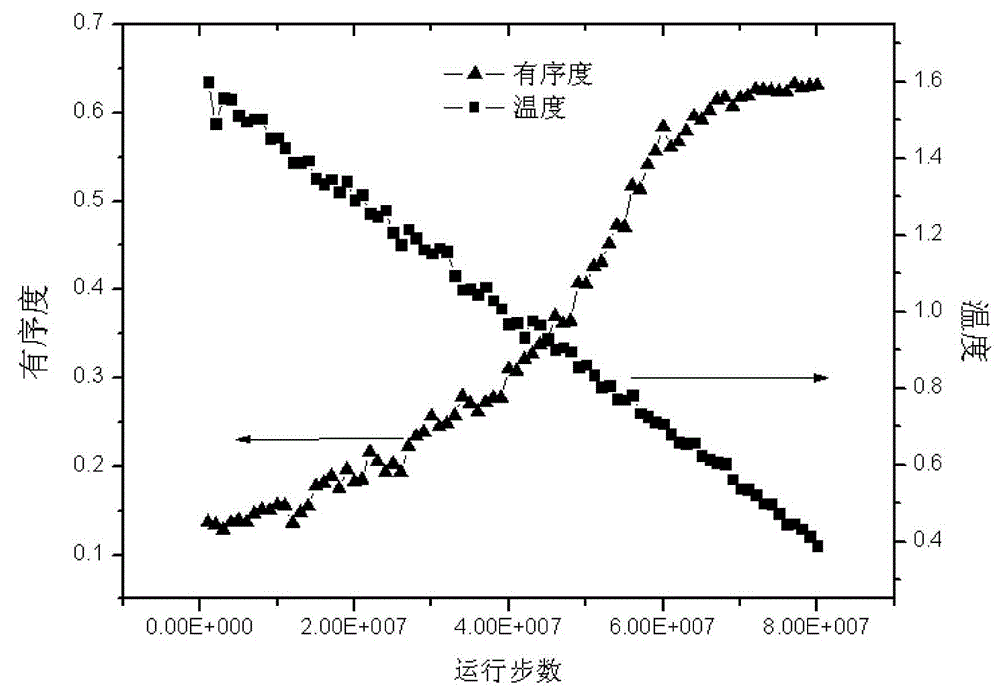

[0029] Establish a coarse-grained polymer model with 1000 particles in each chain and 3 chains, perform NPT equilibrium movement at T=0.1, T=0.1 to T=1.6NPT movement, T=1.6 NPT movement, T=1.6 Cool down to T=0.4NPT movement, then T=0.4 for equilibrium, output the temperature, step number, and atomic coordinates during the deformation process. It can be seen from the figure that the degree of order increases rapidly at 40000000 steps, that is, when the temperature is T=0.85. Before that, it is the crystallization nucleation period, and the crystallization is slow, and then it is the growth period, and the crystal grows rapidly. When the temperature drops to T=0.6, the crystallization ends.

Embodiment 2

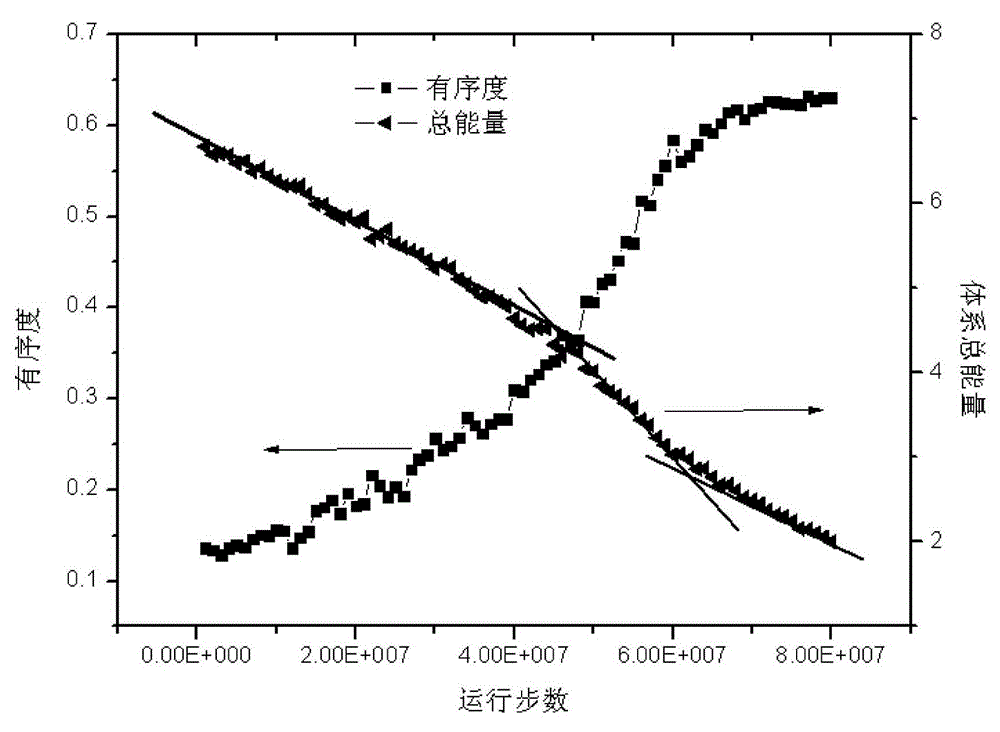

[0031] Establish a coarse-grained polymer model with 1000 particles in each chain and 3 chains, perform NPT equilibrium movement at T=0.1, T=0.1 to T=1.6NPT movement, T=1.6 NPT movement, T=1.6 Cool down to T=0.4NPT movement, then T=0.4 to balance, output the temperature, step number, atomic coordinates and energy changes during the deformation process. It can be seen from the figure that the change process of system energy is consistent with the change process and turning point of crystallinity, which is consistent with the crystallization process.

Embodiment 3

[0033] Establish a coarse-grained polymer model with 1000 particles in each chain and 3 chains, perform NPT equilibrium movement at T=0.1, T=0.1 to T=1.6NPT movement, T=1.6 NPT movement, T=1.6 Cool down to T=0.4NPT movement, then T=0.4 for equilibrium, and output the temperature, steps, volume, etc. during the deformation process. It can be seen from the figure that the reciprocal of the volume has an obvious turning point at about 40 million steps, which is consistent with the change of the crystallinity curve, which further proves the crystallization process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com