Quad flat no-lead package lead frame structure and package structure

A square flat, leadless technology, applied in the direction of electrical solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problems of loss of cutting tool life, gas escape, poor bonding of solder paste, etc., to achieve Reduce wear, improve cutting efficiency, and reduce metal thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

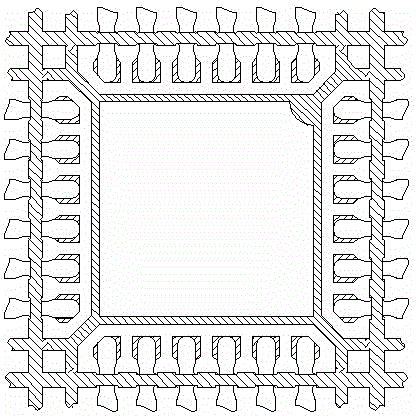

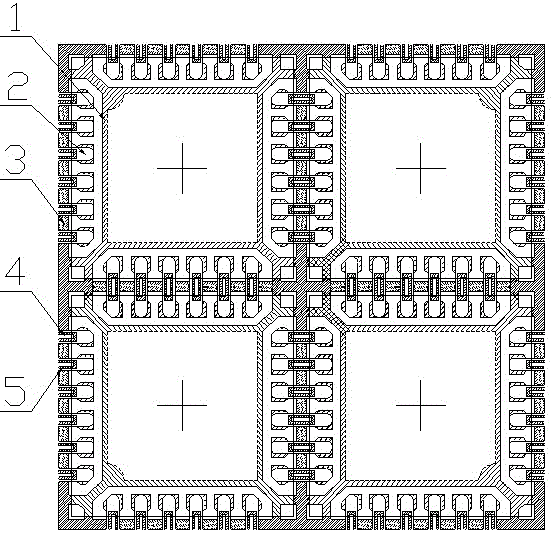

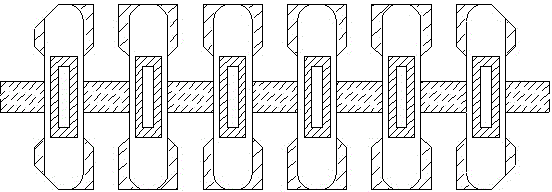

[0028] see figure 2 , the lead frame structure of the present invention is a quadrilateral flat no-lead type package, which includes several carrying units arranged in a matrix and middle ribs 3 for fixing the carrying units between the carrying units, the carrying units include chips The seat 1 and the pin array 2 arranged around the chip seat 1, the middle rib 3 is connected between the pin arrays 2 of two adjacent carrying units, and the back of the pin array 2 is provided with bumps near the middle rib 3 4. The bump 4 is rectangular, and a half-etched groove 5 is arranged around the rectangular bump 4. The bump 4 and the half-etched groove 5 are drawn around the half-etched bump on the back of the pin array near the middle rib. Formed by the pin and the middle rib, the bump 4 will still be partially retained after the rib is removed. The width of the retained part of the bump 4 is 1 / 4~1 / 2 of the width of the pin, and the length extends to 1 / 6~1 / 4, the depth of the half-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com