A kind of hydrocracking catalyst and its preparation method

A hydrocracking and catalyst technology, which is used in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of increasing the production of middle distillate oil, and it is difficult to meet the manufacturer's equipment processing capacity, catalyst reactivity and medium oil selectivity. It can improve the isomerization performance, improve the acid strength and acid density, and improve the isomerization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

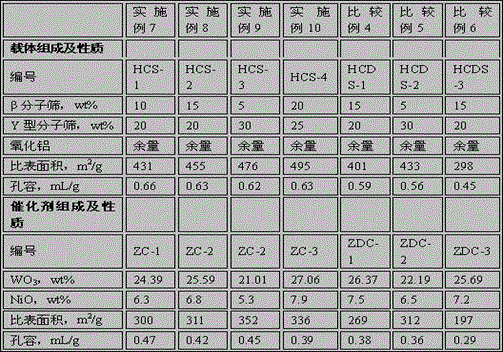

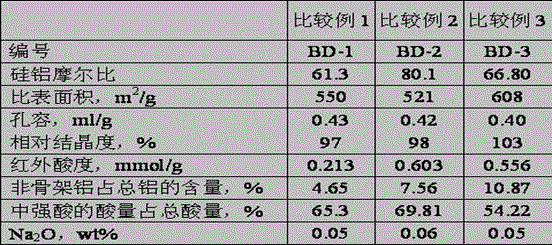

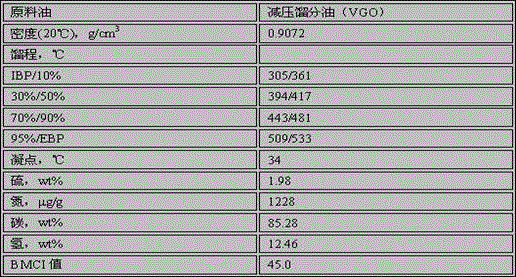

Examples

Embodiment 1

[0044] Take about 3500g of the original powder of β molecular sieve, its chemical silicon aluminum SiO 2 / Al 2 o 3 The (molar ratio) ratio is 22.68, and the sodium oxide content is 0.18wt%. Put the β molecular sieve into the tube furnace, adopt the temperature program method (the heating rate is 100°C / hour), and start to introduce 100wt% water vapor when the temperature of the tube furnace rises to 300°C. 40L / h passed through the β molecular sieve, heated the tube furnace to 550°C, and the constant temperature time was 8 hours. The obtained molecular sieve is coded as BH-1, and its properties are shown in Table 1.

Embodiment 2

[0046] Get about 3500g of the former powder of β molecular sieve, with embodiment 1. Put the molecular sieve into the tube furnace, adopt the temperature program method (heating rate is 100°C / hour), and start to introduce 100wt% water vapor when the temperature of the tube furnace rises to 300°C, and the water vapor is 70L per kilogram of β molecular sieve / h passes through β molecular sieve, heats the tube furnace to 620°C, and the constant temperature time is 8 hours. The obtained molecular sieve is coded as BH-2, and its properties are shown in Table 1.

Embodiment 3

[0048] Weigh 50g of BH-1 molecular sieve into a closed flask with a reflux device, add 400ml of NaOH aqueous solution with a concentration of 0.04mol / L, the weight ratio of NaOH aqueous solution to BH-1 molecular sieve is 8:1, and keep the temperature at 95°C Stir for 2.0 hours, filter, and wash the filter cake with hot deionized water, and stop washing when the pH value of the washing liquid is close to 7. The filter cake was dried in an oven at 120° C. for 5 hours to obtain the β-type molecular sieve of the present invention, which is numbered BJ-1. The properties of the molecular sieve are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com