Production method of 5XXX-serial aluminum alloy large-diameter thin-walled pressure-resisting pipe

A super-large diameter, production method technology, applied in metal processing, tubular articles, metal processing equipment, etc., can solve the problems of poor fusion welding performance, poor fusion welding performance, difficult welding seams, etc., and achieve good weld consistency and welding. The effect of good seam strength and high pressure resistance in the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 5083 aluminum alloy pipe welding

[0017] (1) Material preparation: the specification (length×width×thickness) is 6180mm×2308mm×35mm hot-rolled sheet;

[0018] (2) Curling (or rolling) the hot-rolled plate on a special large-scale plate rolling machine to make it roll into a circular drum with an effective inner diameter of Φ700mm;

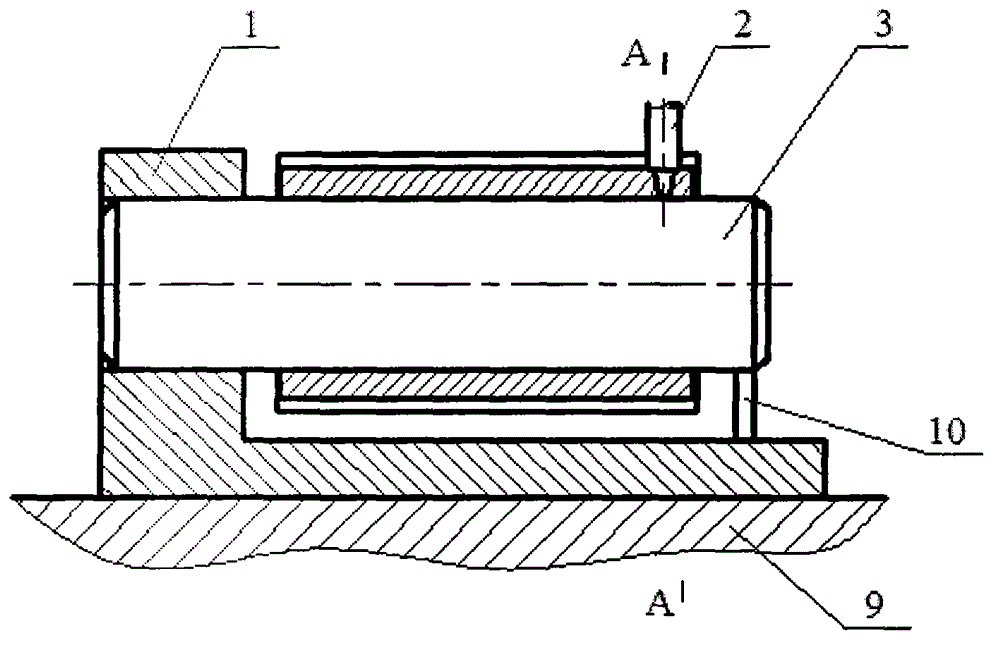

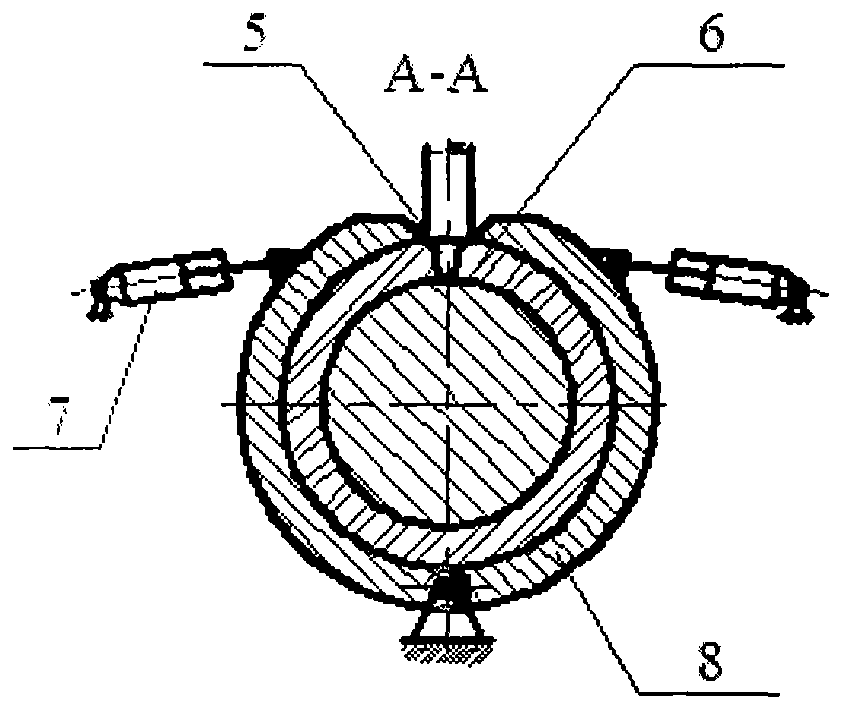

[0019] (3) Put the welding clamp body 1 first (such as figure 1 , figure 2 shown) is installed on the workbench 9 of the friction stir welding machine, and then the rolled aluminum alloy tube 6 is installed on the positioning mandrel 3 of the welding clamp body 1, and the weld seam 5 is at the position of the positioning mandrel 3 at the same time At the position of the upper busbar, the aluminum alloy tube 6 is clamped on the positioning mandrel 3 through a special circular clamp 8 and a hydraulic clamping mechanism 7 .

[0020] (4) Adjust the position of the stirring head 2 so that it welds from one end of the weld to the...

Embodiment 2

[0024] Embodiment 2 5052 aluminum alloy pipe welding

[0025] (1) Material preparation: the specification (length×width×thickness) is 6180mm×3956mm×60mm hot-rolled sheet;

[0026] (2) Curling (or rolling) the hot-rolled plate on a special large-scale plate rolling machine to make it roll into a circular drum, and the effective inner diameter of the drum is Φ1200mm;

[0027] (3) Put the welding clamp body 1 first (such as figure 1 , figure 2 shown) is installed on the workbench 9 of the friction stir welding machine, and then the rolled aluminum alloy tube 6 is installed on the positioning mandrel 3 of the welding clamp body 1, and the weld seam 5 is at the position of the positioning mandrel 3 at the same time At the position of the upper busbar, the aluminum alloy tube 6 is clamped on the positioning mandrel 3 through a special circular clamp 8 and a hydraulic clamping mechanism 7 .

[0028] (4) Adjust the position of the stirring head 2 so that it welds from one end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Σ0.2 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap