High-efficiency electric ESR (Electroslag Refining/Remelting) ingot casting device

An electroslag ingot and high-efficiency technology, applied in the field of electroslag remelting equipment, can solve the problems of ingot shape limitation, low work efficiency, complex structure, etc., and achieve the effects of low cost, high work efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

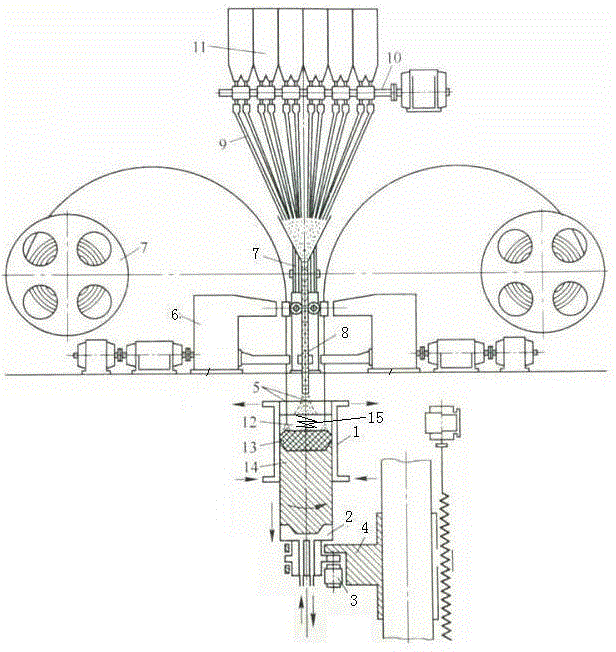

[0015] Example 1: See figure 1 , Efficient electric slag ingot melting casting device, the melting casting device includes feeding devices, feeding devices, control devices, reaction devices, and bottom water tank components.Between the bottom water tank parts, the molten casting device also includes a water -cooled crystallizer 1, which is set on the outside of the reaction device.Inside.The overall structure of the invention is clever, the structure is compact, and the practicality is strong; the technical solution is set in the mixing device to make the metal liquid in the metal pool more fully stirred, which is convenient for forming various shapes of steel ingots.higher efficiency.

Embodiment 2

[0016] Example 2: See figure 1 As a improvement of the present invention, the input device includes material grooves 11, raw material quantitative 10, which is set below the groove.The remaining structures and advantages are exactly the same as Example 1.

Embodiment 3

[0017] Example 3: See figure 1 As a improvement of the present invention, the feeding device includes the guide pipe 8 and the feed pipe 9. The feed pipe is set up above the guide pipe, and the feed pipe is set to a cone.The remaining structures and advantages are exactly the same as Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap