Electric worm-gear airplane braking system and method for operating braking system

A worm gear, electric brake technology, applied in aircraft braking arrangements, vehicle components, brakes, etc., can solve problems such as far away, and achieve the effects of reducing weight, fast response, and saving space occupancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

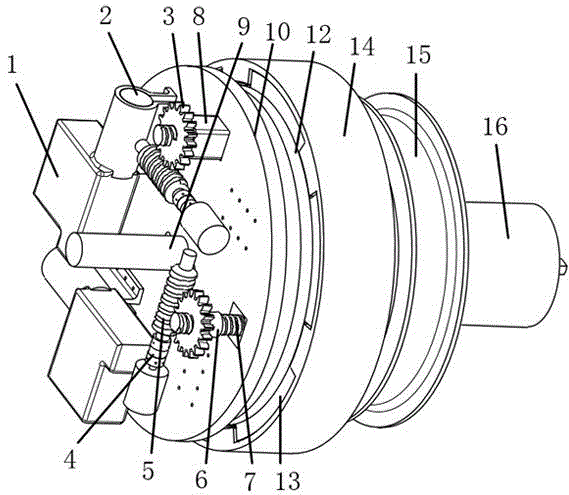

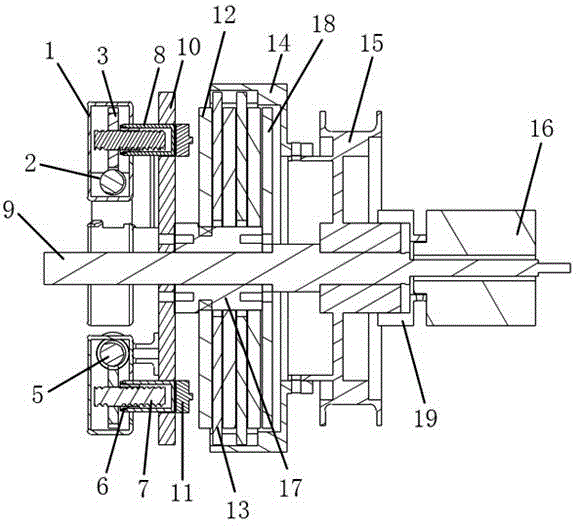

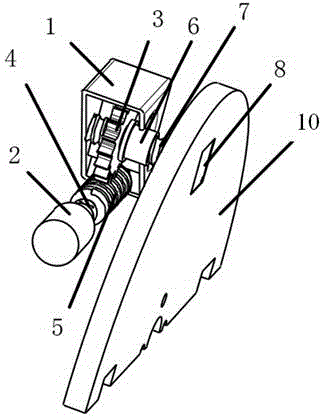

[0026] All-electric braking system with worm and gear actuation is attached figure 1 , 2 , 3, 4, 5, and 6. The working principle of the all-electric brake system with worm gear actuation will be described here.

[0027] The working principle of the all-electric brake system with worm gear actuation is:

[0028] (a) When the aircraft wheel receives the brake command, the motor 2 starts, the rotor rotates, the worm 5 is driven to rotate through the coupling 4, the worm 5 rotates to drive the worm wheel 3 to rotate, and the worm wheel 3 drives the ball screw 7 connected to it Rotate together, the nut 6 on the ball screw is fixedly connected with the outer cylinder 8 of the screw nut. Since the outer cylinder 8 is restricted by the square groove opened on the support cover 10 of the electric actuator, the outer cylinder 8 has no gap around the axis of the ball screw. Rotational freedom, so the ball nut 6 and the outer cylinder 8 can only advance or retreat along the axial direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com