Suspended detachable protective cover and its application in on-line transformation of belt conveyor

A belt conveyor and suspension technology, applied in the field of protective covers, can solve the problems of potential safety hazards and the non-stopping of belt conveyors, and achieve the effects of improving work efficiency, eliminating potential safety hazards, and ensuring progress requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

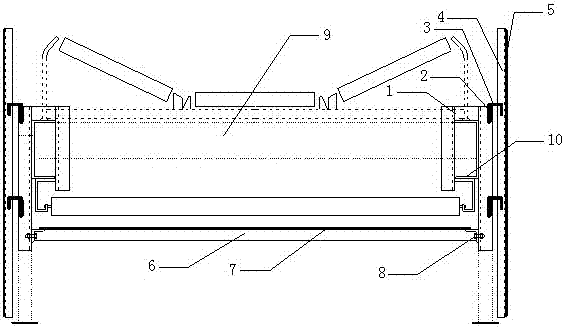

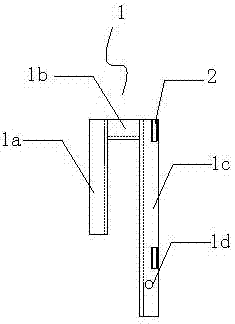

[0029] figure 2 It is a structural schematic diagram of the first component of the embodiment of the suspended detachable protective cover of the present invention. As shown in the figure, the first member 1 is a hook made of L63*6 angle steel, the hook head 1a is parallel to the hook handle 1c, and the connecting part 1b is welded vertically to them; two hook handles 1c are welded up and down. The bolt sleeve made of 22*2 steel pipe, the lower end of the hook handle 1c is provided with a bolt hole 1d; the hook head 1a of the first member 1 is suspended and hooked into the wing plate 10 of the upper and lower roller bracket beams of the belt conveyor; The first member 1 is a group of two arranged along the length of the belt conveyor, and the distance between the two first members 1 is 1000mm;

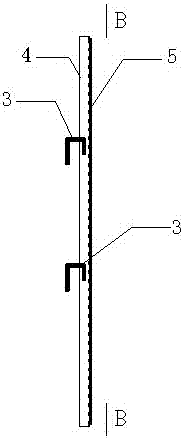

[0030] image 3 is a schematic structural diagram of the second component of the embodiment of the present invention, Figure 6 for image 3 B-B sectional view in . The second co...

Embodiment 2

[0033] Baosteel raw material direct delivery system Phase I and II integrated transfer station reconstruction project is located at the intersection of Weisan Road and Jinger Road in Baosteel factory area. There are 15 east-west and 9 north-south 24 belt conveyors in 4 systems on it, which are responsible for the transfer of raw materials to blast furnaces, sintering, steelmaking, etc. 24 hours a day. This project is based on the premise that Baosteel Ironworks Phase I and Phase II comprehensive transfer stations are not in production, and the 60-ton columns, 400-ton beams, and 120-ton platform boards of the transfer stations are replaced online; The 24 belt conveyors were dismantled, repaired and replaced one by one. The 7.2-meter and 11-meter platforms of the transfer station are shared by multiple parallel belt conveyors. One of them will be out of service for renovation, and the surrounding ones need to be produced and transported normally. Therefore, isolation measures mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com