Graphite boat identification system and method for silicon chip production

A recognition system, graphite boat technology, applied in the direction of general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of error-prone, poor product traceability, manual input can not meet the automation system, etc., to reduce errors, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

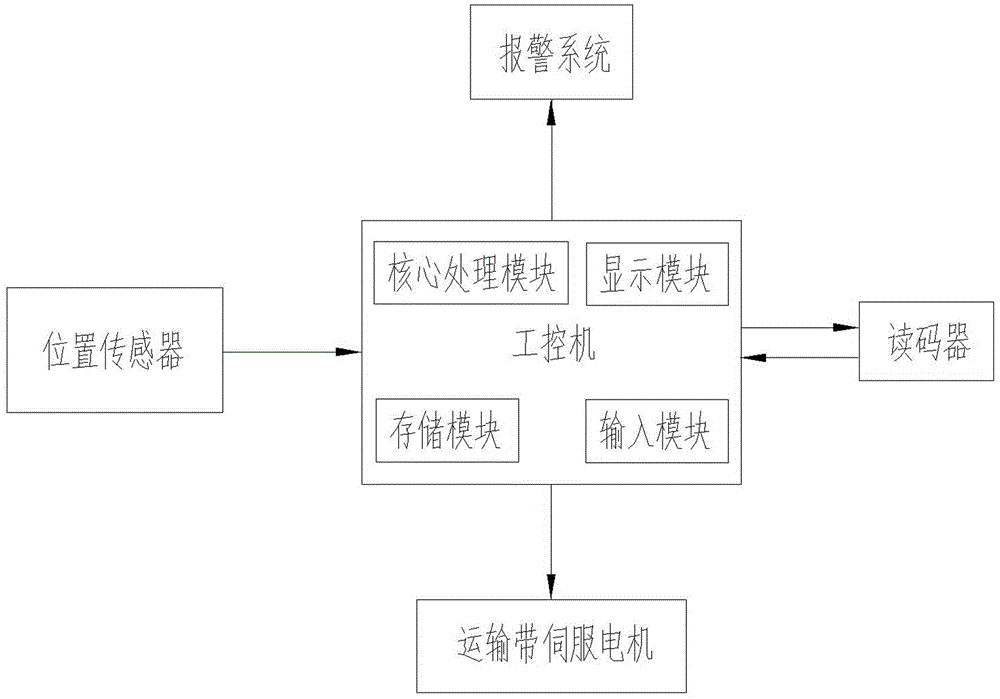

[0025] Such as figure 1 As shown, the graphite boat identification system proposed by the present invention includes: a machine platform, a conveyor belt arranged on the machine platform, and a graphite boat arranged on the conveyor belt for loading silicon wafers, and also includes a code reader, a position sensor and industrial computer.

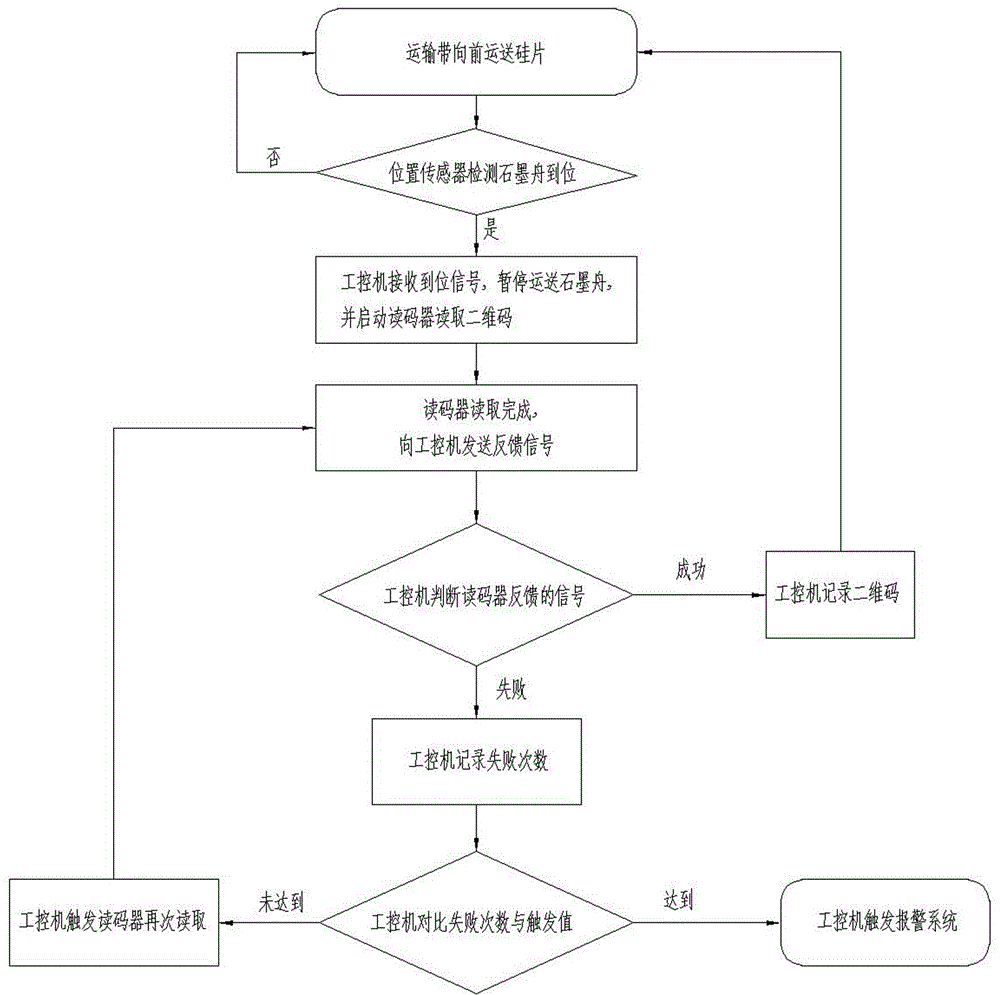

[0026] Two-dimensional codes with different contents are engraved on the same side surface of each graphite boat, and the two-dimensional codes are used to record the boat number or process parameters, etc., and the code reader reads the two-dimensional code information and sends it to the industrial computer for recording. Because the graphite boat is black and has an anti-reflection coating on the surface, it is difficult to read the two-dimensional code. In order to ensure the correct reading of the code reader, the best way is to engrave the two-dimensional code on the graphite boat to a depth greater than or equal to 0.3mm , and adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com