Wet-process desulfurization wastewater utilization system and process

A technology for wet desulfurization and waste water, which is applied in separation methods, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of hidden dangers of filter mud transportation and high economic cost investment, and solve the problem of water resource loss and improve Dust removal effect and loss saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

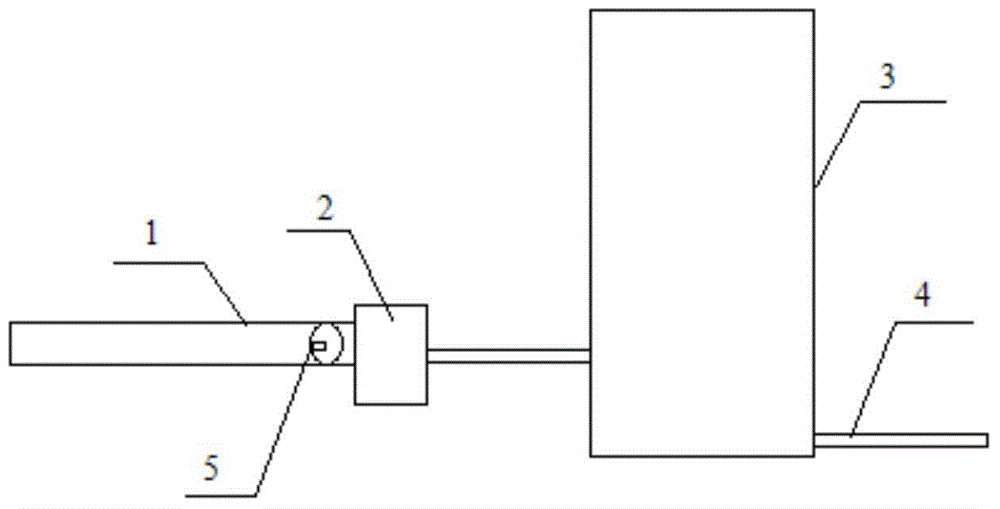

[0023] Such as figure 1 As shown, a wet desulfurization wastewater utilization system of the present invention includes a flue inlet 1, a dust collector 2, an absorption tower 3 and a waste water discharge pipeline 4 connected in sequence, wherein, in the flue inlet 1, there is Gas-liquid two-phase flow atomizer 5.

[0024] In the above embodiment, in order to enhance the utilization effect of waste water, the gas-liquid two-phase flow atomizer is preferably arranged at the flue gas inlet where the flue inlet 1 is connected to the dust collector 2; preferably, the gas-liquid two-phase There are multiple groups of flow atomizers 5, and multiple groups of gas-liquid two-phase flow atomizers 5 are arranged in the cross-section of the flue in a mesh structure, so that the original flue gas can fully contact the atomized wastewater, and fully improve the utilization of wastewater. efficiency, and can effectively prevent the atomized wastewater outlet of the gas-liquid two-phase fl...

Embodiment 2

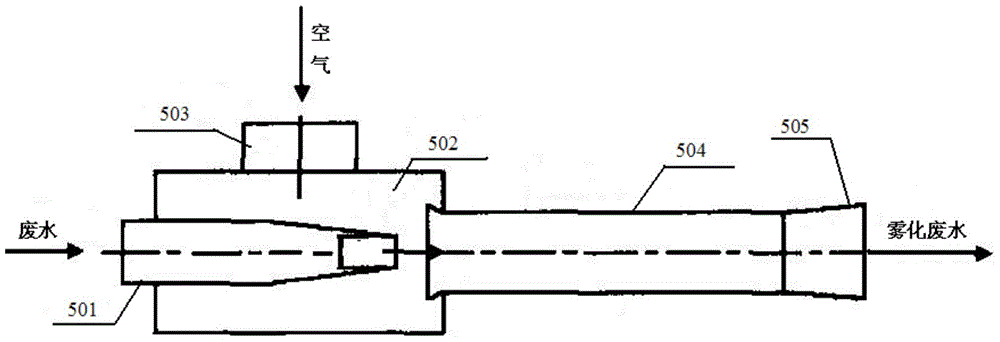

[0031] Such as figure 1 and figure 2 As shown, a wet desulfurization waste water utilization system of the present invention has the same basic settings and applications as in Example 1. In order to enhance the comprehensive utilization effect of waste water removal and further improve the downstream flue gas desulfurization efficiency, the following settings are also included:

[0032] The gas-liquid two-phase flow atomizer 5 includes a nozzle 501, an air chamber 502, a suction pipe 503, a mixing pipe 504, and a diffuser pipe 505, wherein the nozzle 501 is connected to the air chamber 502, and the air chamber 502 is connected to the suction pipe 502 respectively. The tube 503 is connected with the mixing tube 504, the suction tube 503 is connected with the outside air, one end of the mixing tube 504 is adjacent to the nozzle 501, and the other end of the mixing tube 504 is connected with the diffuser tube 505.

[0033] In the above embodiment, in order to enhance the atomiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com