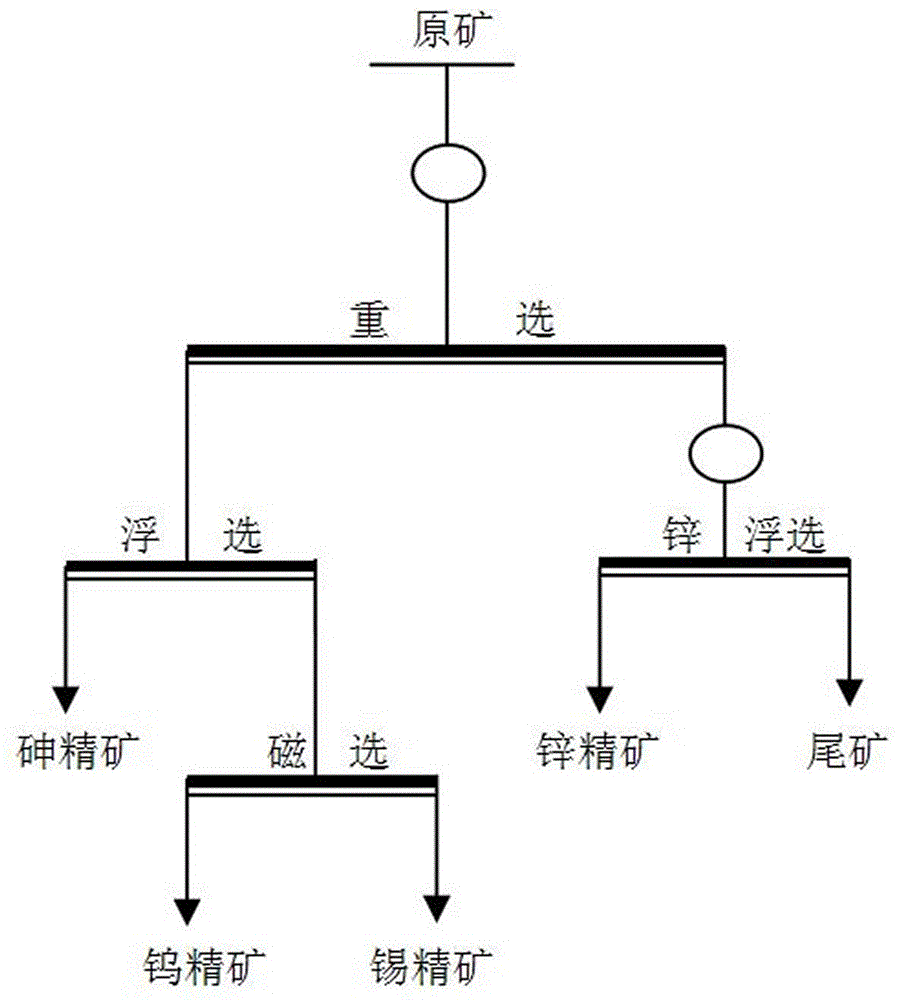

A comprehensive recovery and dressing method for tungsten-tin-zinc polymetallic ore

A beneficiation method, polymetallic technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve problems such as shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The ore contains WO 3 0.141%, Sn0.220%, Zn1.18%, As1.21%, after raw ore grinding, the heavy sand product is obtained through the second-stage shaker separation. The roughing stroke of the first-stage shaker: 15mm, the stroke of the shaker: 290 times min-1, the horizontal water supply: 90mL / s, the water supply to the ore tank: 40mL / s, the transverse inclination of the shaker: 2.5 degrees, the second-stage shaker It is beneficiation, that is, after the raw ore has been roughed and discarded, the concentrate obtained by sweeping the middle ore and the roughed concentrate are combined together as a shaker to feed the ore for tungsten-tin concentration test to obtain tungsten-tin re-separation concentrate. Shaking table stroke: 15mm, shaking table stroke times: 290 times min-1, lateral water supply: 75mL / s, water supply to mine tank: 35mL / s, lateral inclination of shaking table: 2.5 degrees. The heavy sand product is subjected to arsenic flotation, three times of roughing, ...

Embodiment 2

[0022] The ore contains WO 3 0.153%, Sn0.300%, Zn1.08%, As0.87%, after raw ore grinding, the heavy sand product is obtained through two-stage shaker separation. The roughing stroke of the first-stage shaker: 15mm, the stroke of the shaker: 290 times min-1, the horizontal water supply: 90mL / s, the water supply to the ore tank: 40mL / s, the transverse inclination of the shaker: 2.5 degrees, the second-stage shaker It is beneficiation, that is, after the raw ore has been roughed and discarded, the concentrate obtained by sweeping the middle ore and the roughed concentrate are combined together as a shaker to feed the ore for tungsten-tin concentration test to obtain tungsten-tin re-separation concentrate. Shaking table stroke: 15mm, shaking table stroke times: 290 times min-1, lateral water supply: 75mL / s, water supply to mine tank: 35mL / s, lateral inclination of shaking table: 2.5 degrees. The heavy sand product is subjected to arsenic flotation, three times of roughing, and the...

Embodiment 3

[0024] The ore contains WO 3 0.147%, Sn0.234%, Zn1.20%, As1.18%, after raw ore grinding, the heavy sand product is obtained through two-stage shaker separation. The roughing stroke of the first-stage shaker: 15mm, the stroke of the shaker: 290 times min-1, the horizontal water supply: 90mL / s, the water supply to the ore tank: 40mL / s, the transverse inclination of the shaker: 2.5 degrees, the second-stage shaker It is beneficiation, that is, after the raw ore has been roughed and discarded, the concentrate obtained by sweeping the middle ore and the roughed concentrate are combined together as a shaker to feed the ore for tungsten-tin concentration test to obtain tungsten-tin re-separation concentrate. Shaking table stroke: 15mm, shaking table stroke times: 290 times min-1, lateral water supply: 75mL / s, water supply to mine tank: 35mL / s, lateral inclination of shaking table: 2.5 degrees. The heavy sand product is subjected to arsenic flotation, three times of roughing, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com