Gear appearance defect detection and sorting system based on machine vision

A sorting system and gear technology, which is applied in the direction of sorting and optical testing for flaws/defects, etc., can solve problems such as low efficiency and precision, complicated measurement process, and numerous detection items, and achieve convenient maintenance, high measurement accuracy, and system structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

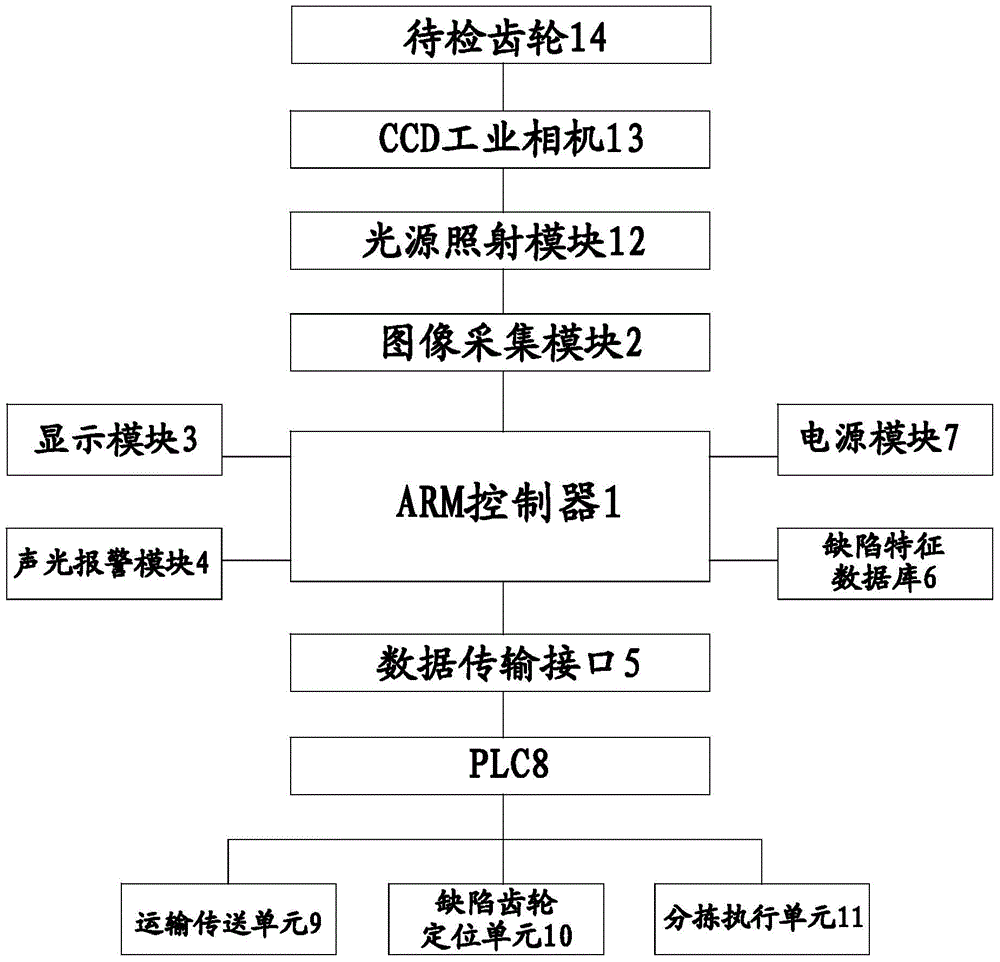

[0009] figure 1 It is a schematic structural diagram of the machine vision-based gear appearance defect detection and sorting system of the present invention. The machine vision-based gear appearance defect detection and sorting system includes an ARM controller 1, an image acquisition module 2, a display module 3, an acousto-optic alarm module 4, Data transmission interface 5, defect characteristic database 6, power supply module 7, PLC 8, transport transmission unit 9, defect gear positioning unit 10, sorting execution unit 11, light source irradiation module 12, CCD industrial camera 13, gear to be tested 14; where:

[0010] The ARM controller 1 is respectively connected to the image acquisition module 2, the display module 3, the sound and light alarm module 4, the data transmission interface 5, the defect feature database 6, and the power supply module 7, The data transmission interface 5 is respectively connected to the ARM controller 1 and the PLC 8, and the PLC 8 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com