A live repair method for electrolytic cell aluminum busbar in strong magnetic field environment

A live repair and strong magnetic field technology, applied in the field of aluminum smelting, can solve problems such as affecting the stable operation of normal production electrolytic cells, damage to busbars in drains, paralysis of aluminum electrolytic series, etc., achieving significant promotion value and use value, and ensuring the diversion effect. , good conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

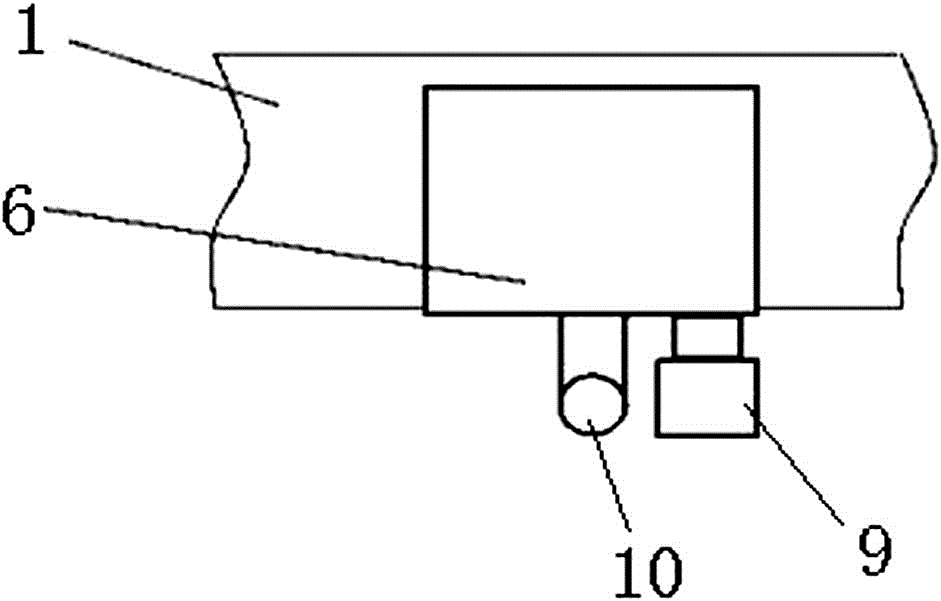

[0018] A live repair method for an aluminum busbar of an electrolytic cell in a strong magnetic field environment, comprising the following steps:

[0019] a. First use a chisel to clean the burnt aluminum busbar 1 oxide layer and impurities;

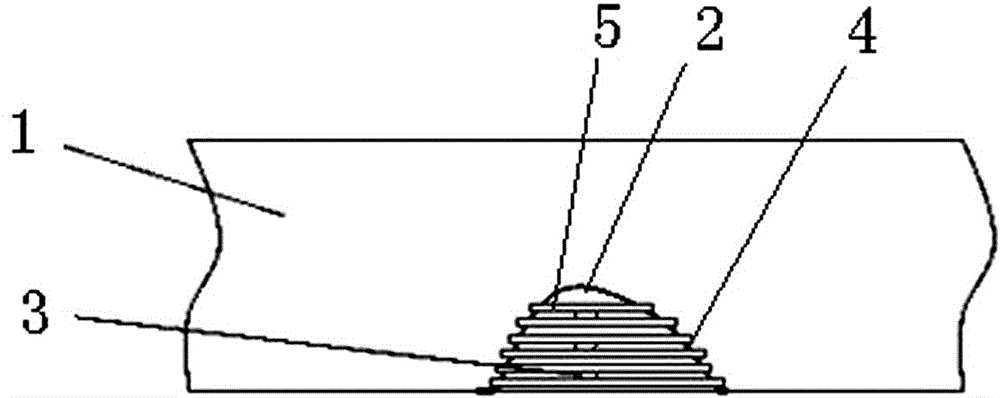

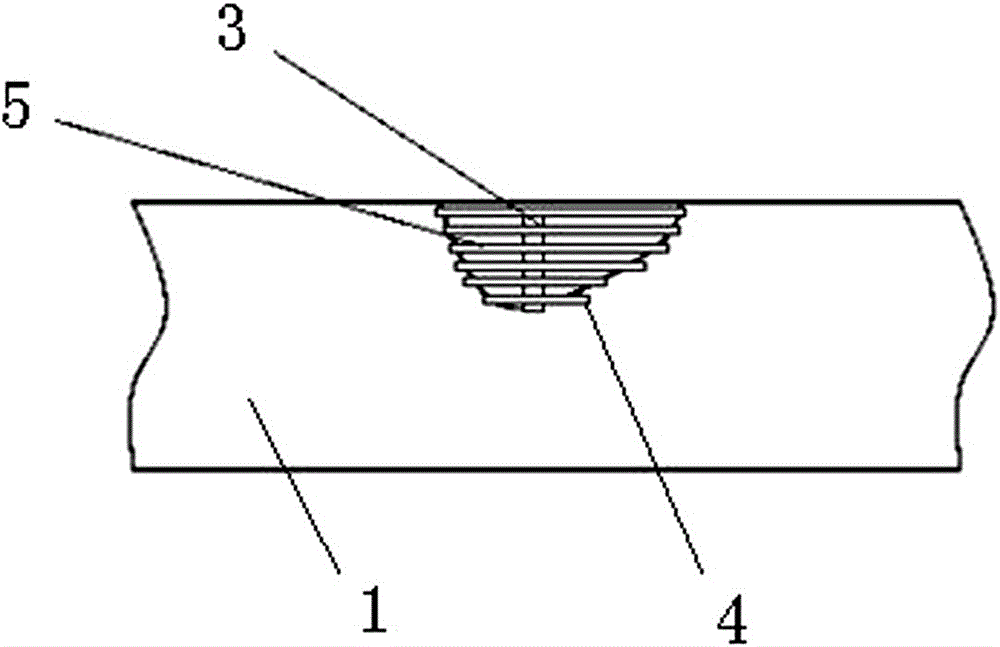

[0020] b. If figure 1 , 2 As shown, in the middle of the damaged surface 2 of the aluminum bus bar and along the longitudinal direction of the aluminum bus bar, a number of holes are set at intervals, and a strong conductive metal rod I3 is preset in each hole, and a Φ20mm thick cold-drawn copper rod is selected. 50mm, the interval between adjacent holes is 10mm;

[0021] c. Set one-to-one corresponding positioning grooves 4 at the edge of the damaged surface of the aluminum busbar and along the lateral direction of the aluminum busbar. Each set of corresponding positioning grooves is preset with a strong conductive metal rod Ⅱ5, and a Φ10mm thick cold-drawn copper rod is selected. Each positioning groove Evenly spaced, each position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com