Heavy plate feeder

A plate feeder, heavy-duty technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that rolling bearings are easily damaged by impact, dust is easy to enter the inside of the bearing, and the current of the motor is unstable, so as to reduce maintenance and maintenance frequency, improve the normal operation cycle, and reduce the effect of maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

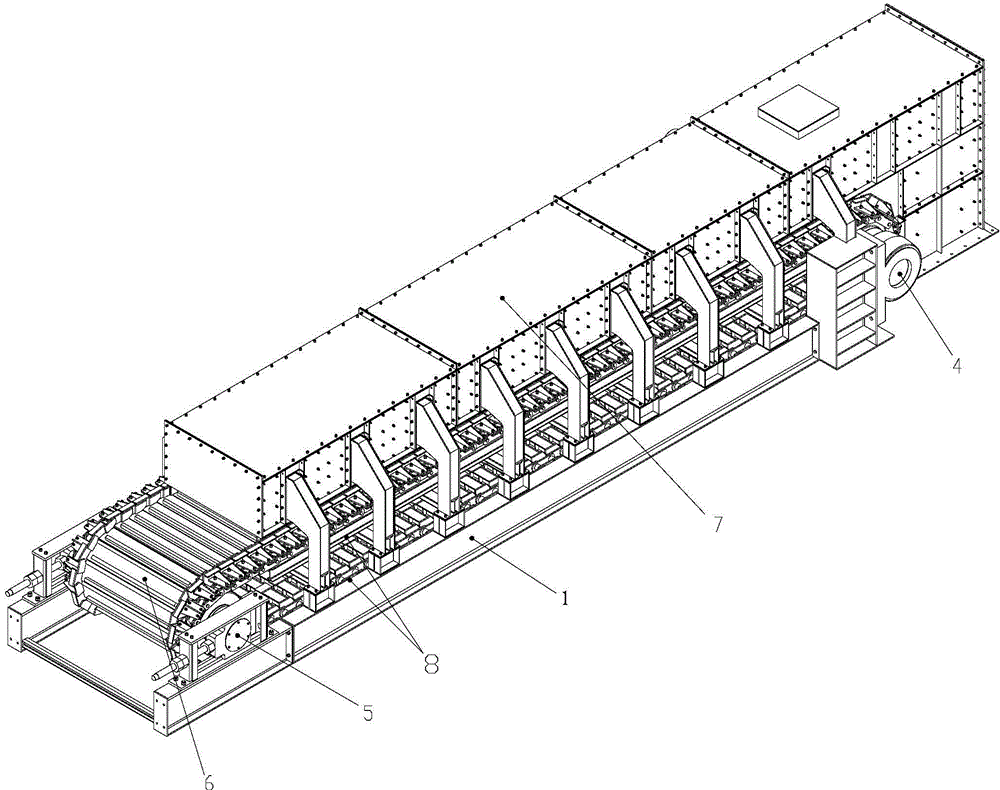

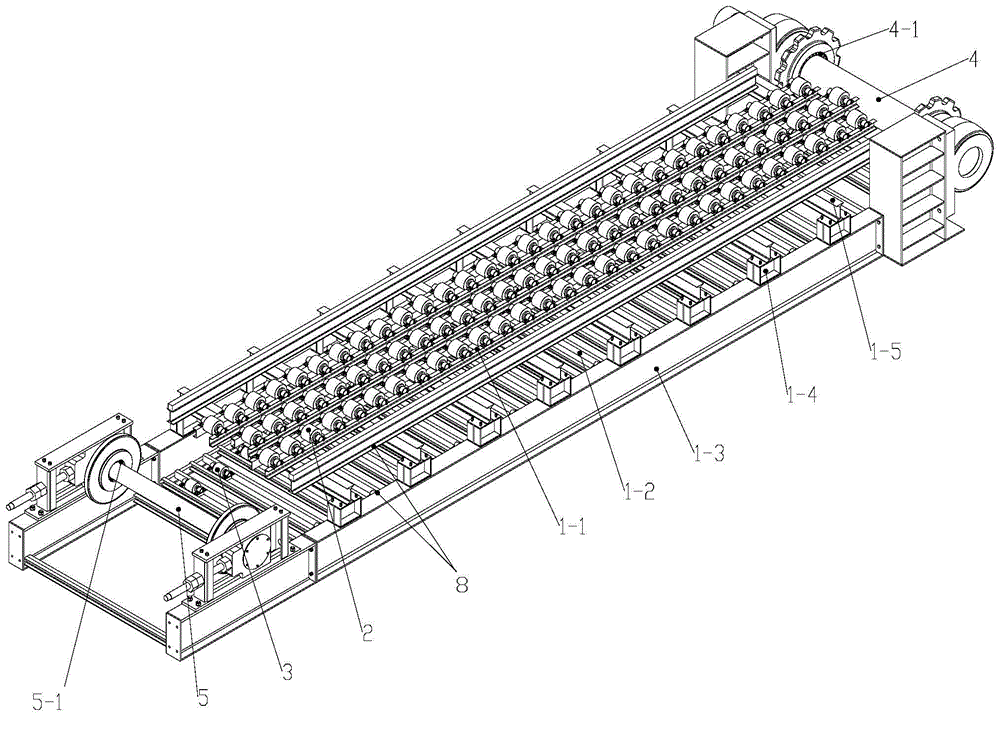

[0032] see Figure 1 to Figure 4 , a heavy-duty apron feeder, mainly including a frame 1, an upper supporting wheel device 2, a lower supporting wheel device 3, a head sprocket driving device 4, a tail sprocket tensioning device 5, a carrying mechanism 6 and a material guide protection device7. Wherein said carrying mechanism 6 is mainly made of conveying chain 6-1 and several conveying troughs 6-2 installed on the conveying chain, and an upper roller device and a lower roller device supporting the carrying mechanism are installed on the frame.

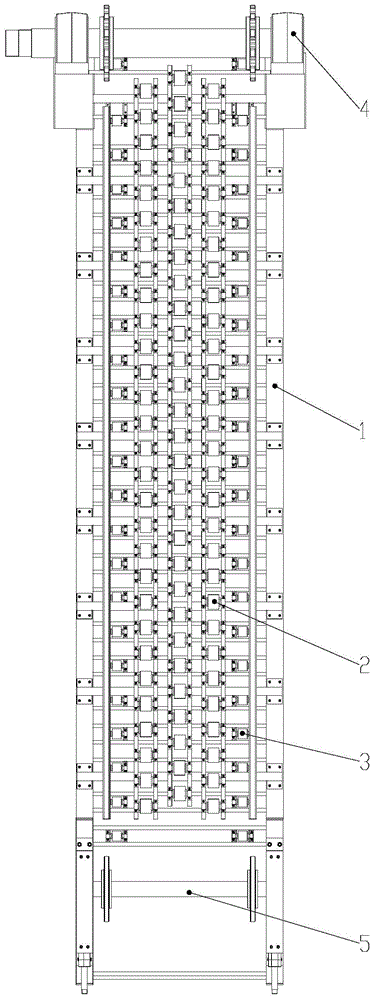

[0033] see Figure 2 to Figure 7 , the structure of the above-mentioned upper supporting wheel device 2 and the lower supporting wheel device 3 is exactly the same. In this embodiment, only the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com