Method for surface coating of lithium ion battery anode material with nanoscale iron phosphate

A lithium-ion battery, cathode material technology, applied in nanotechnology, battery electrodes, nanotechnology and other directions for materials and surface science, can solve problems such as uneven distribution, affect practical utility, etc., achieve simple and mature technology, reduce safety Hidden danger, avoid the effect of increasing the interface resistance of the material surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

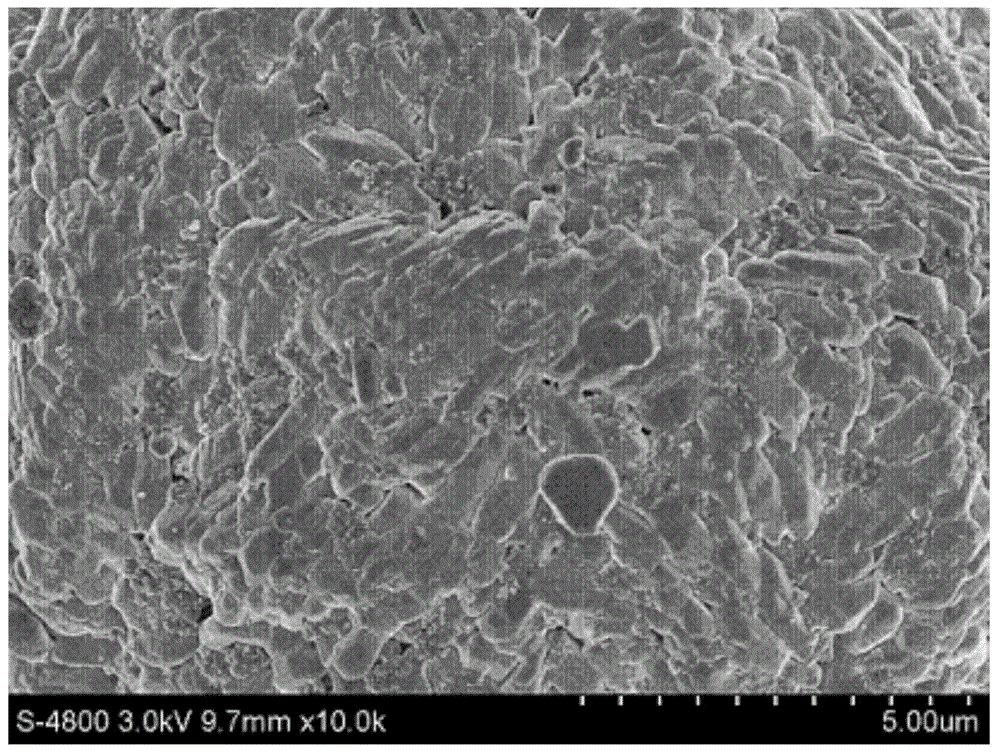

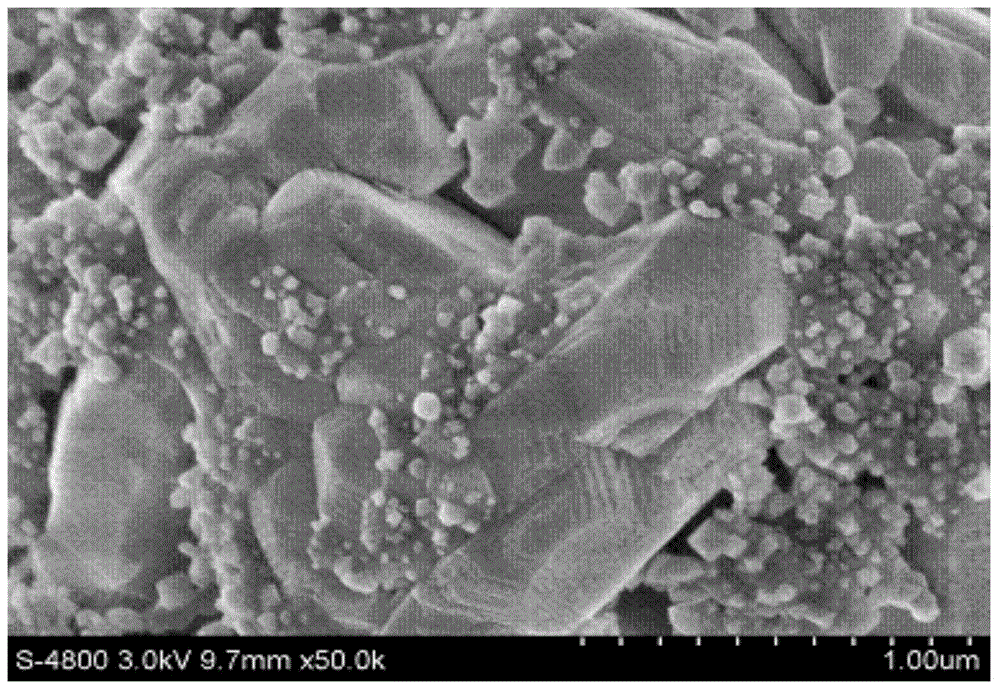

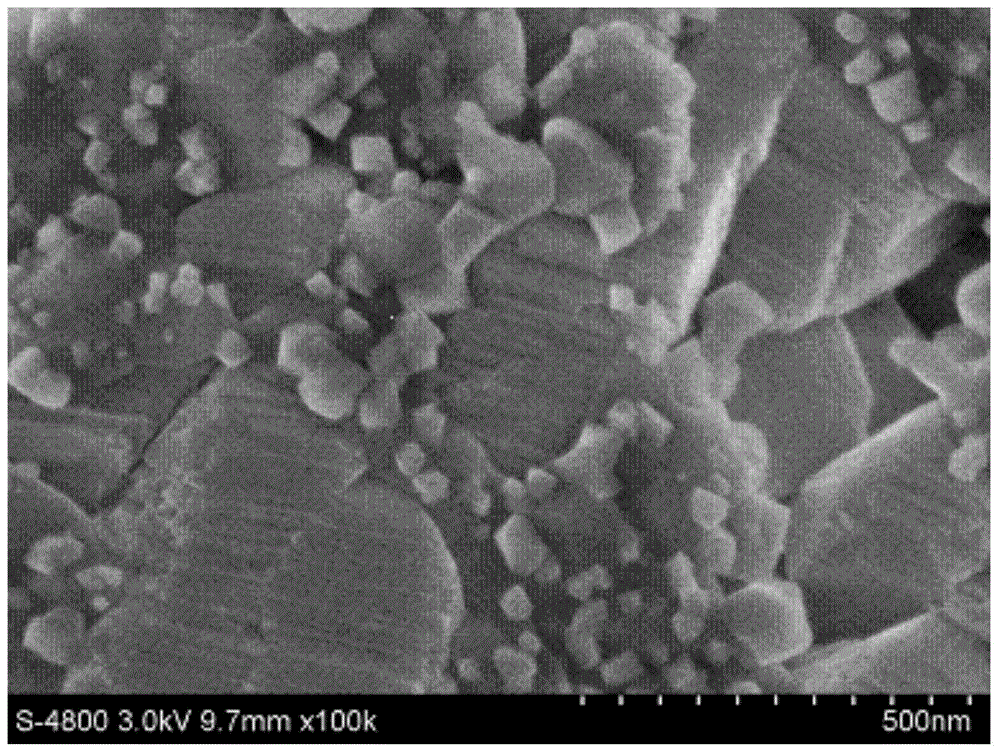

[0049] 2% nanoscale FePO 4 coated LiNi 0.5 co 0.2 mn 0.3 o 2 Cathode material

[0050] Step 1: Preparation of Homogeneous FePO 4 the solution

[0051] ⑴ Preparation of ferric nitrate solution

[0052] Weigh analytically pure Fe(NO 3 ) 3 9H 2 O is used as iron source, is mixed with deionized water into 1.0mol / L iron salt aqueous solution;

[0053] Weigh analytically pure NH 4 h 2 PO 4 As a phosphorus source, prepare a 1.0mol / L phosphate aqueous solution with deionized water;

[0054] ⑵ Preparation of homogeneous FePO 4 the solution

[0055] First, pump the prepared iron salt solution into the stainless steel reaction kettle with a metering pump, set the reaction temperature at 50°C, and the stirring speed of the reaction kettle at 150r / min, then pump the phosphate solution into the iron salt solution with a metering pump to control the solution. The molar ratio of P / Fe in the mixture is 1.02, stir evenly to form a homogeneous brown FePO without precipitation 4 ...

Embodiment 2

[0067] 1% nanoscale FePO 4 coated LiNi 0.5 co 0.2 mn 0.3 o 2 Material

[0068] Change the concentration of iron salt aqueous solution and phosphate aqueous solution in Example 1 to 0.5mol / L, and other steps remain unchanged. After coating, LiNi 0.5 co 0.2 mn 0.3 o 2 ,D 50 =8.569μ㎡, specific surface area 0.36m 2 / g.

Embodiment 3

[0070] 3% nanoscale FePO 4 coated LiNi 0.5 co 0.2 mn 0.3 o 2 Material

[0071] Change the concentration of iron salt solution and phosphate solution in Example 1 to be 1.5mol / L, and the other steps remain unchanged. After coating, LiNi 0.5 co 0.2 mn 0.3 o 2 , D50=8.832μ㎡, specific surface area 0.56m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com