Device using high-voltage pulsed discharge to break excess sludge and application method thereof

A high-voltage pulse discharge, excess sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of high energy consumption, low cracking rate, high cost, etc. high energy consumption, high safety and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

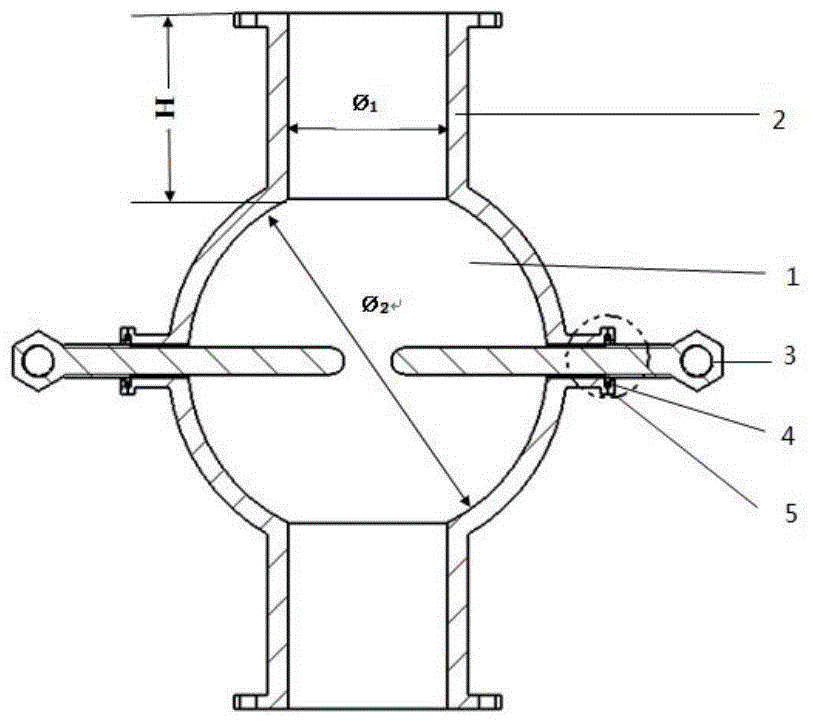

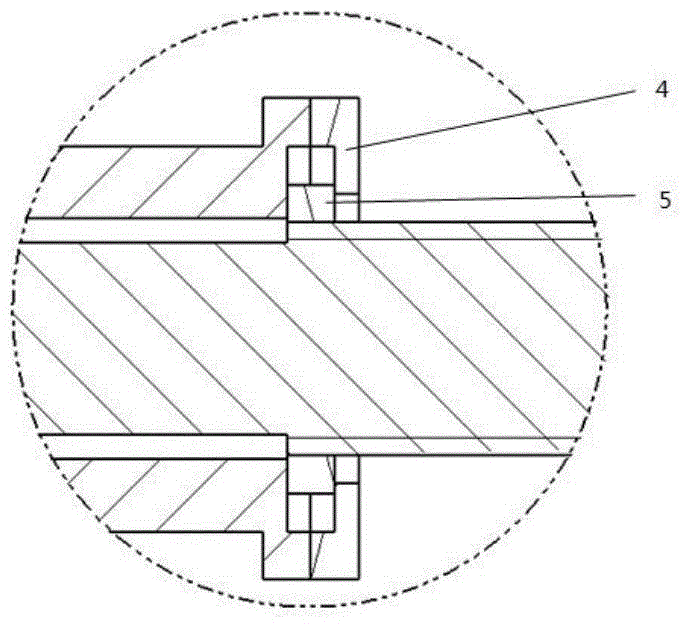

[0035] A device for cracking excess sludge using high-voltage pulse discharge, comprising a pressure-resistant container 1, a sludge flow pipe 2, a discharge electrode 3, a side cover 4, and an insulating nut 5; the pressure-resistant container 1 is a shell, and The pressure vessel 1 is symmetrically provided with two sludge flow pipes and two electrode sockets; the discharge end of the discharge electrode 3 penetrates into the container through the electrode socket; the insulating nut 5 is set on the outside of the discharge electrode 3 to fix the electrode on the On the pressure vessel 1; the side cover 4 is set outside the insulating nut 5 to fix the nut on the pressure vessel 1; except for the electrode discharge part, the outer surface of the device is coated with insulating material;

[0036] Wherein, the pressure-resistant container 1 is a spherical shell structure, the wall thickness of the container is ≥ 1cm, the volume of the spherical container is 3-5L, and its diame...

Embodiment 2

[0038] A device for cracking excess sludge using high-voltage pulse discharge, comprising a pressure-resistant container 1, a sludge flow pipe 2, a discharge electrode 3, a side cover 4, and an insulating nut 5; the pressure-resistant container 1 is a shell, and The pressure vessel 1 is symmetrically provided with two sludge flow pipes and two electrode sockets; the discharge end of the discharge electrode 3 penetrates into the container through the electrode socket; the insulating nut 5 is set on the outside of the discharge electrode 3 to fix the electrode on the On the pressure vessel 1; the side cover 4 is set outside the insulating nut 5 to fix the nut on the pressure vessel 1; except for the electrode discharge part, the outer surface of the device is coated with insulating material;

[0039] Wherein, the pressure-resistant container 1 is a square shell structure, the wall thickness of the container is ≥ 1cm, and the volume of the container is 3-5L; the diameter of the di...

Embodiment 3

[0041]According to the requirement of disintegration of excess sludge, the device is connected through the sludge flow pipe 2 to form a multi-level disintegration system, so that the excess sludge can achieve the desired disintegration effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com