Modified calcium oxide expansion agent for cement concrete

A technology of cement concrete and calcium oxide, which is applied in the field of building materials, can solve the problems of no improvement in hydration, achieve the effects of improving shrinkage compensation, reducing usage, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

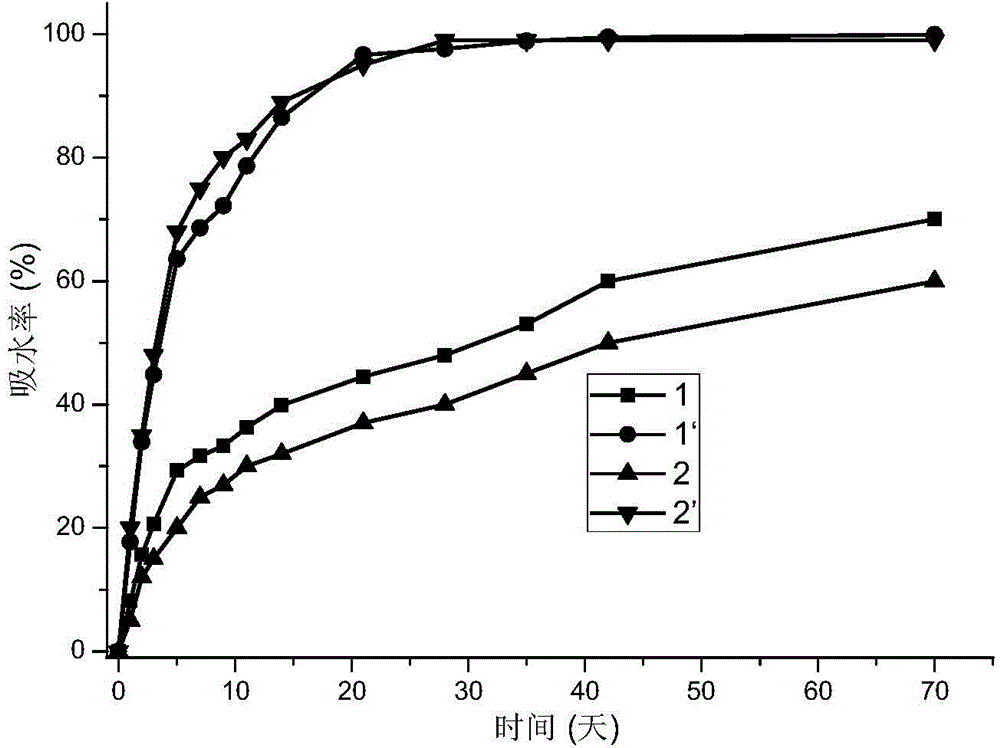

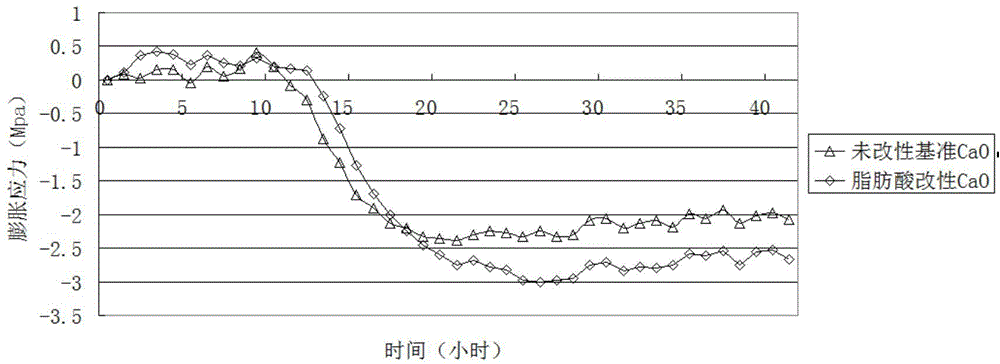

[0023] Weigh the calcium oxide expansion agent and lauric acid with a mass ratio of 999:1, mix them evenly, and grind them in an electromagnetic vibrating mill for 1 min. The free calcium oxide (f-CaO) of the calcium oxide expansion agent is 60%. , the specific surface area is 100m 2 / kg, the modified calcium oxide expansion agent 1 for cement concrete is obtained after grinding.

[0024] In contrast, the unmodified calcium oxide expansion agent used in the present embodiment is marked as 1'.

Embodiment 2

[0026] Weigh the calcium oxide expansion agent and myristic acid with a mass ratio of 99:1, mix them evenly, and grind them in an electromagnetic vibrating mill for 5 minutes. The free calcium oxide (f-CaO) of the calcium oxide expansion agent is 70 %, the specific surface area is 200m 2 / kg, the modified calcium oxide expansion agent 2 for cement concrete is obtained after grinding.

[0027] In contrast, the unmodified calcium oxide expansion agent used in the present embodiment is marked as 2'.

Embodiment 3

[0029] Weigh the calcium oxide expansion agent and arachidic acid with a mass ratio of 95:5, mix them evenly, and grind them in a planetary ball mill for 10 min. The free calcium oxide (f-CaO) of the calcium oxide expansion agent is 80%, and the ratio Surface area is 400m 2 / kg, the modified calcium oxide expansion agent 3 for cement concrete is obtained after grinding.

[0030] In contrast, the unmodified calcium oxide expansion agent used in this embodiment is marked as 3'.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com