Preparation method for beta-chitosan with different molecular weights

A technology of chitosan and molecular weight, applied in the field of marine chemical engineering, can solve difficult problems and achieve the effect of less reagents, less time-consuming and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

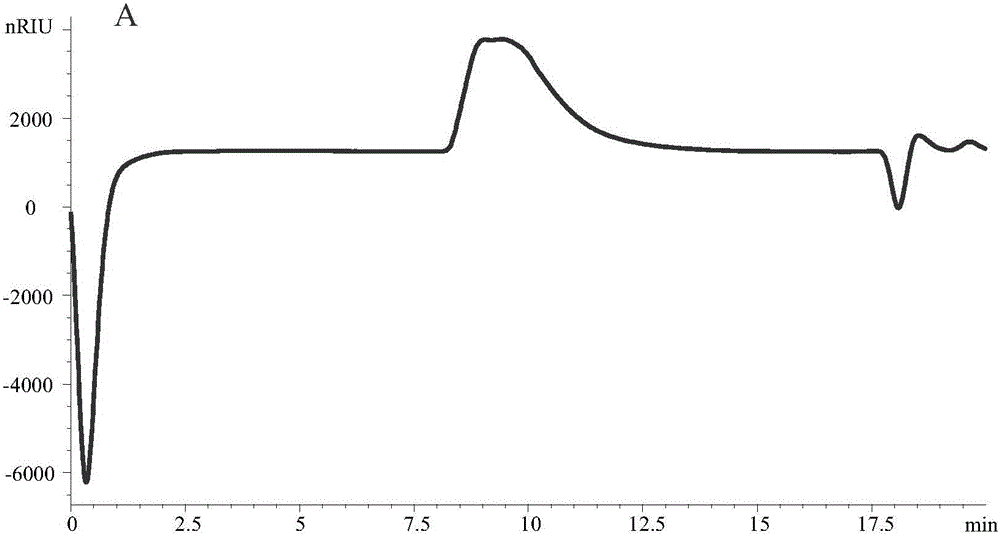

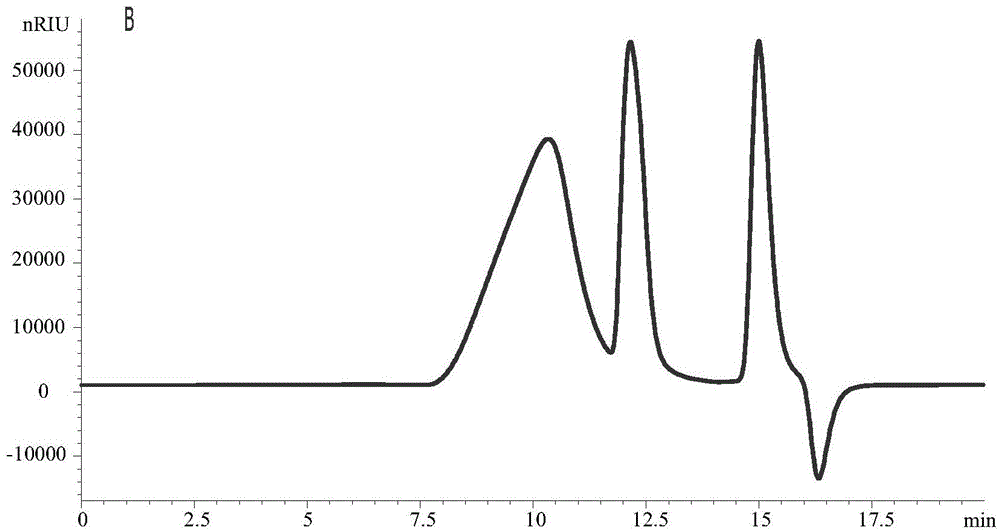

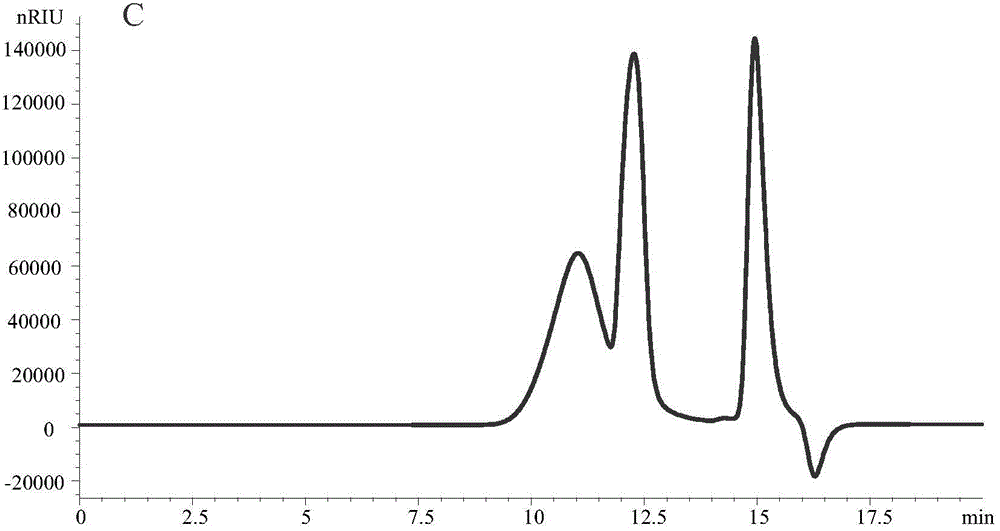

[0025] Take by weighing 12g beta-chitosan, molecular weight is 4717KDa, degree of deacetylation is 91.04%, is dissolved in the glacial acetic acid solution of 400mL 2% (volume concentration), stirring and dissolving until obtaining clear, homogeneous concentration is 3% (mass concentration) β-chitosan. Take multiple 100ml microwave reactors, add 50ml of the above-mentioned dissolved β-chitosan to each reactor, and then add 1.5mL of 30% hydrogen peroxide respectively, at 600W, 70°C, the stirring speed is 600r / min , respectively reacted for 10min, 15min, 20min, 25min, 30min, 40min, 60min, 80min, 100min, 180min, will obtain different reaction solutions dialyzed, lyophilized and carry out the determination of molecular weight and structure (see Figure 1A , Figure 1B , Figure 2A with Figure 2B ). The weight average molecular weight (Mw) and number average molecular weight (Mn) of β-chitosan degradation products were analyzed by high performance gel exclusion chromatography (...

Embodiment 2

[0031] Weigh 12g of β-chitosan with a molecular weight of 4717KDa and a degree of deacetylation of 91.04%, dissolve it in 400ml of glacial acetic acid solution with a volume concentration ratio of 2%, stir and dissolve until a clear, homogeneous concentration of 3% β-chitosan is obtained. Chitosan. Get a plurality of 100ml microwave reactors, add 50ml of the above-mentioned dissolved β-chitosan in each reactor, and then add different amounts of 30% hydrogen peroxide to the reactors successively, and the different amounts of 30% hydrogen peroxide is 0.5 mL, 1mL, 1.5mL, 3mL, 4mL, 5mL, 10ml, 600W, 70℃, 700r / min. After reacting for different times, the obtained solutions were dialyzed with dialysis bags for 2-3 days to remove salt ions, rotated under high pressure at 50°C, and then freeze-dried under reduced pressure, and the molecular weight and structure were determined (see Figure 1A , Figure 1C , Figure 2A with Figure 2C). The weight average molecular weight (Mw) and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com