Method for preparing halogen-free flame retardant polypropylene modified material

A flame-retardant polypropylene, modified technology, applied in the field of preparation of modified polypropylene modified materials, to achieve the effects of simple processing technology, increased production capacity, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

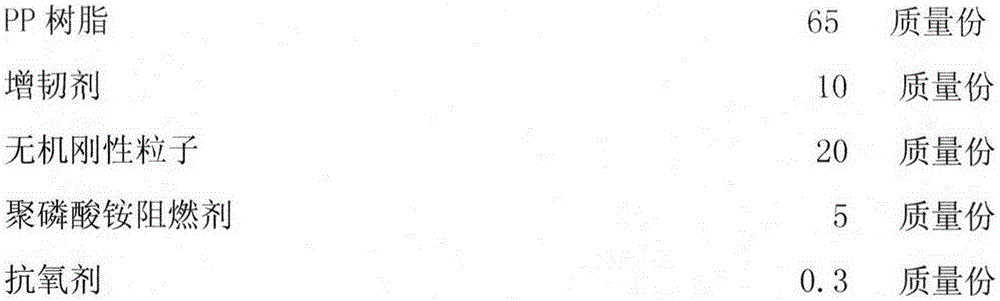

Embodiment 1

[0018] (1) Process formula

[0019]

[0020] (2) Processing technology

[0021] Mix 65 parts by mass of PP resin, 10 parts by mass of toughening agent, 20 parts by mass of inorganic rigid particles, 5 parts by mass of ammonium polyphosphate II, and 0.3 parts by mass of antioxidant in a high-speed mixer at 80-90°C 5 minutes, and then extrude and granulate on the twin-screw extruder. The temperature of the extruder is: 185°C for the first interval, 190°C for the second and third intervals, 195°C for the fourth, fifth, sixth, seventh, and eighth intervals, and 190°C for the ninth interval. ℃, three-stage vacuuming is carried out in the third, fifth, and seventh intervals. Extruded into strips, tested for flame retardancy according to UL94 standards, tested for bending properties according to GB / T9341-2000, tested for impact properties in GB / T1843-1996, tested for tensile properties in GB1040-92, and tested in GB / T3682-2000 melt flow rate.

[0022] According to this process,...

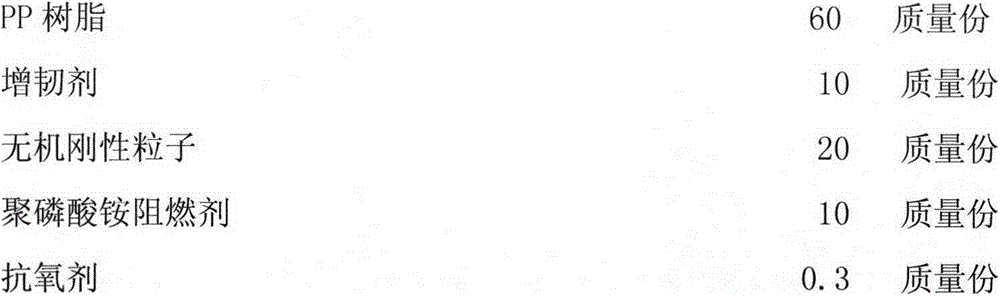

Embodiment 2

[0024] Process recipe

[0025]

[0026] The above formula was molded according to the processing technology of Example 1 to obtain a flame-retardant polypropylene modified material. Its properties are shown in Tables 1 and 2.

Embodiment 3

[0028] Process recipe

[0029]

[0030]

[0031] The above formula was molded according to the processing technology of Example 1 to obtain a flame-retardant polypropylene modified material. Its performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com